A method for reducing the moisture content of silver flotation second-stage press filter residue

A technology of press filter residue and flotation, which is applied in flotation, solid separation, process efficiency improvement, etc. It can solve the problems of small pressing area of diaphragm plate, unfavorable recovery of water-soluble zinc, and high moisture content of slag, so as to speed up water volatilization, reduce Equipment maintenance difficulty, effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

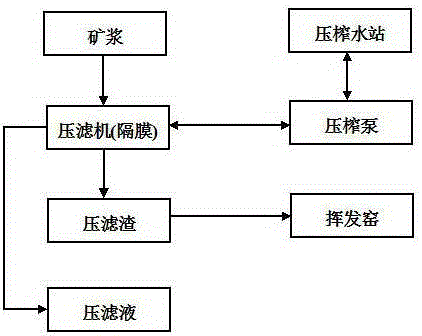

Image

Examples

Embodiment 1

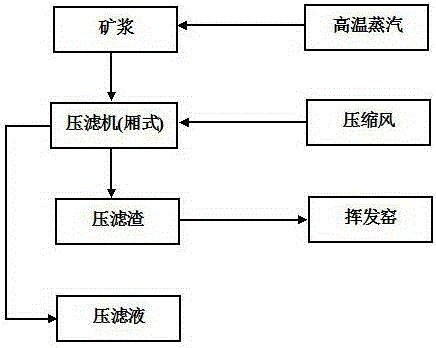

[0011] Example 1: A zinc hydrometallurgy company processes 200t of zinc concentrate on average per day, and performs two-stage pressure filtration on the acid leaching slag slurry after zinc smelting for silver flotation. Press filter process such as figure 2 As shown, the process features are as follows:

[0012] ① Use high-temperature steam to heat the acid leaching slag pulp for 1 hour to obtain a uniform temperature pulp.

[0013] ②Introduce the heated acid leaching slag slurry to a volume of 10m 2 In the inner cavity of the filter press, close the feed valve of the filter press after the inner cavity of the filter press is filled with pulp.

[0014] ③Using three units with a gas volume of 20m 3 The compressed air blower blows the slurry, and the blowing time is 30 minutes.

[0015] ④ After the injection is completed, close the valve of the compressor fan, and return the machine to unload the slag.

[0016] The ore pulp after the second-stage pressure filtration was ...

Embodiment 2

[0017] Example 2: A zinc hydrometallurgy company handles 800t of zinc concentrate per day, and performs two-stage pressure filtration on the acid leaching slag slurry after zinc smelting for silver flotation. Adopt the technological process identical with embodiment 1, this technological feature is as follows:

[0018] ① Use high-temperature steam to heat the acid leaching slag pulp for 1 hour to obtain a uniform temperature pulp.

[0019] ②Introduce the heated acid leaching slag slurry to a volume of 16m 2 In the inner cavity of the filter press, close the feed valve of the filter press after the inner cavity of the filter press is filled with pulp.

[0020] ③Using three sets of gas volume are 25m 3 The compressed air blower blows the slurry, and the blowing time is 30 minutes.

[0021] ④ After the injection is completed, close the valve of the compressor fan, and return the machine to unload the slag.

[0022] The ore pulp after the second-stage pressure filtration was t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com