Electric low-power-consumption valve

An electric valve, low power consumption technology, applied in the direction of sliding valve, lift valve, valve details, etc., can solve the problems of unstable working performance of electric valve, increased opening and closing force, and malfunction of drainage valve, so as to achieve the flow of water supply. Good performance, small fluid pressure loss, and the effect of overcoming scaling and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

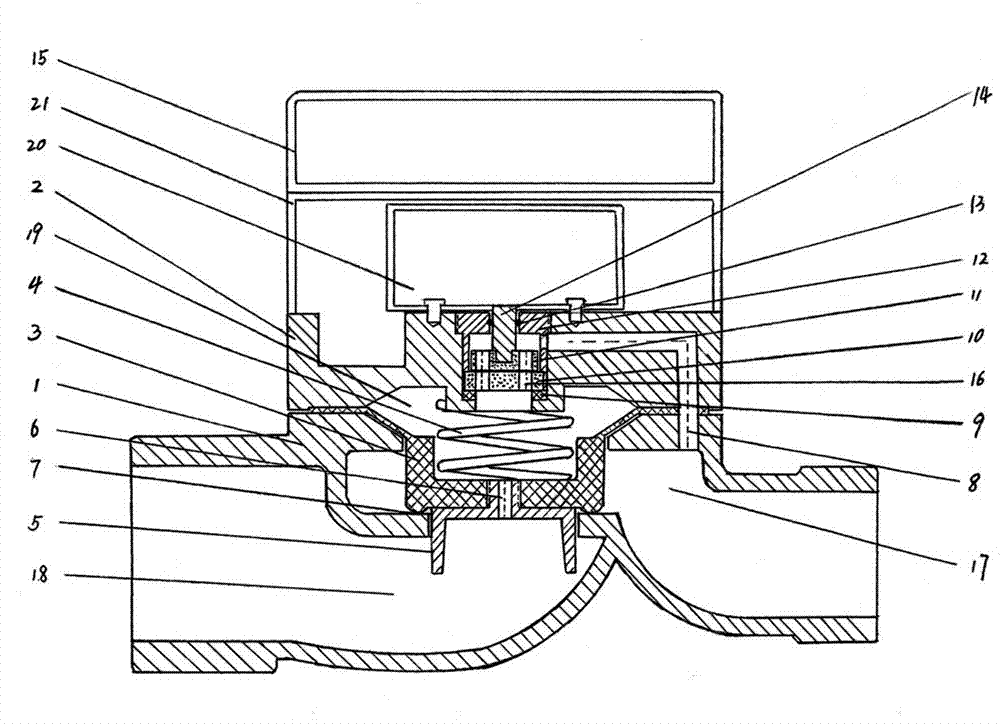

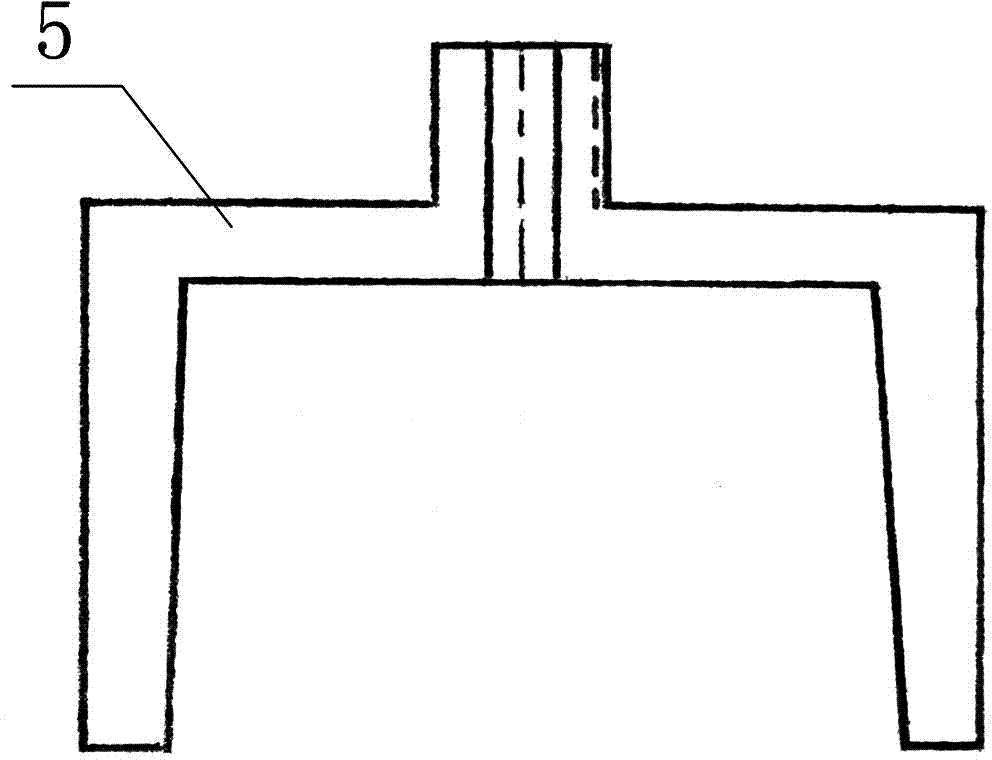

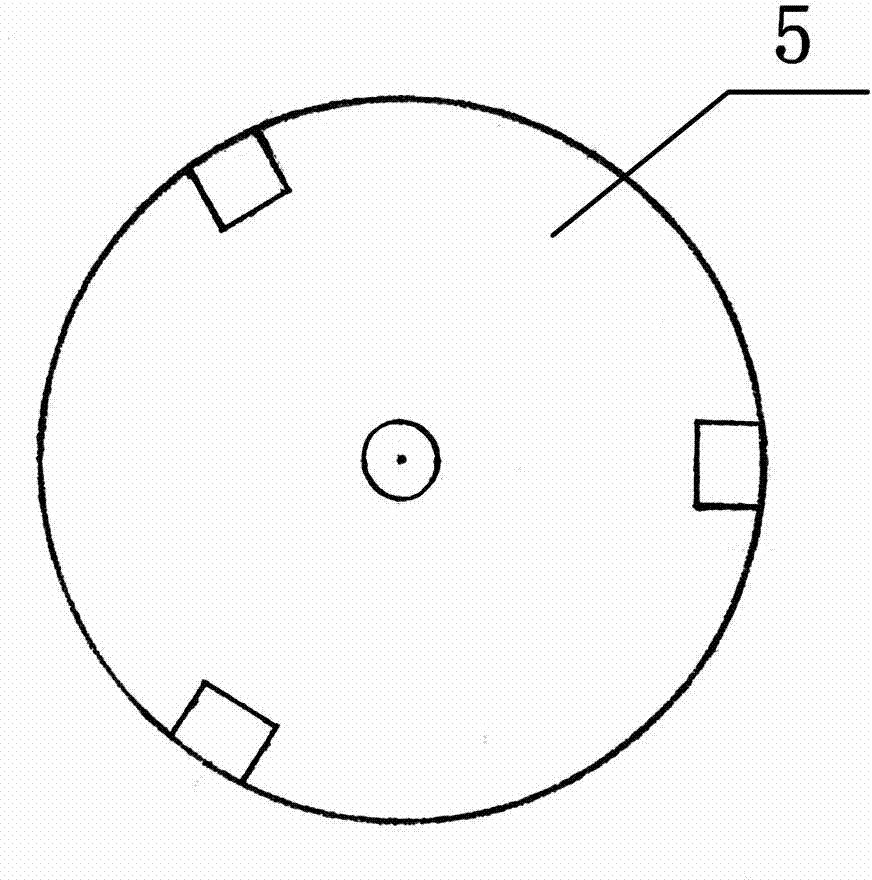

[0014] Such as figure 1 As shown, the low-power electric valve of the present invention includes a valve body 1, a valve cover 2, an electric actuator 20, an electrical shield 21 and a junction box 15 that are solidly connected as one, wherein the left end of the valve body 1 is provided with a water inlet cavity 18 , the right end is provided with a water outlet chamber 17, the water inlet chamber 18 and the water outlet chamber 17 are either turned off or opened by controlling the integral rubber sealing valve core 3, and the pressure control chamber 19 communicates with the inlet pressure diversion hole 6 and the pressure relief diversion hole 8 . In the low power consumption electric valve of the present invention, a pot-shaped integral rubber sealing valve core 3 is fixedly connected between the valve body 1 and the valve cover 2, and a pressure control chamber 19 is formed between the valve cover 2 and the integral rubber sealing valve core 3 . The integral rubber seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com