Regenerated concrete dewatering pipe and manufacturing method thereof

A technology for recycling concrete and drainage pipes, applied in the field of drainage pipes, can solve the problems of unsatisfactory connection effect, difficult positioning of connection and high cost of raw materials, and achieves the effects of ingenious structural design, simple processing and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

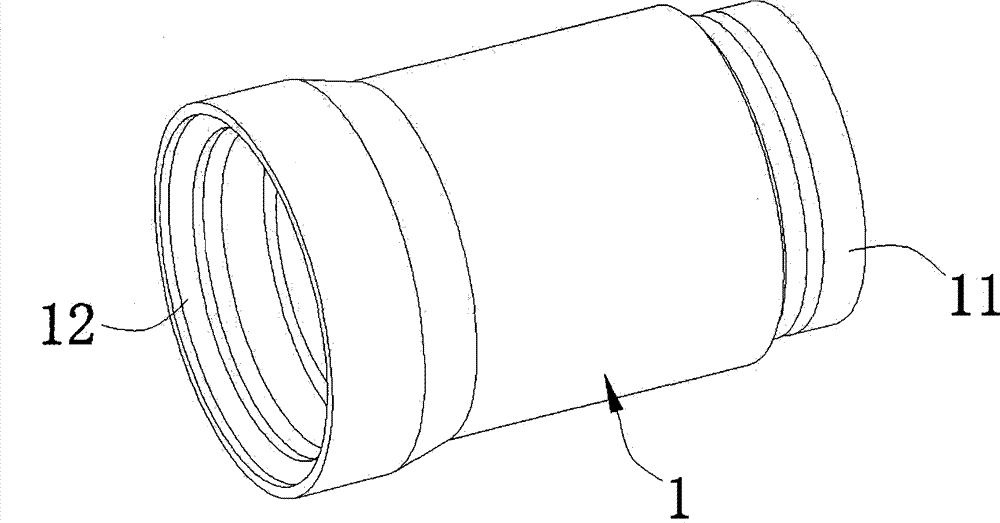

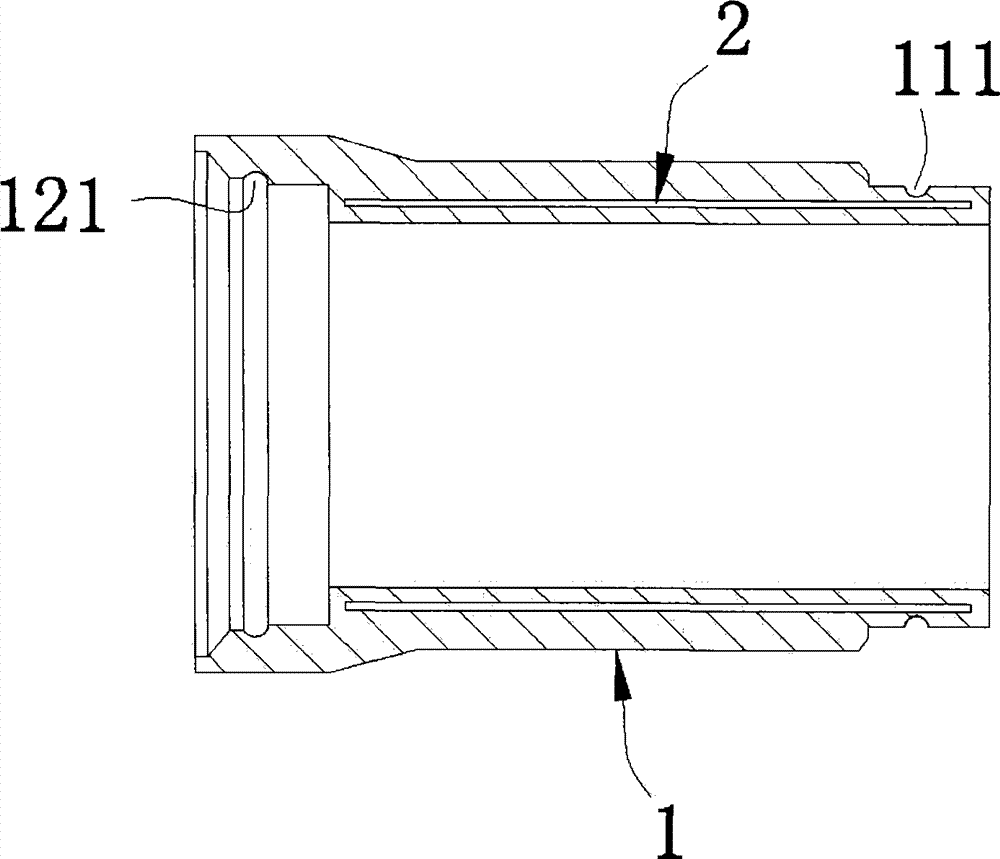

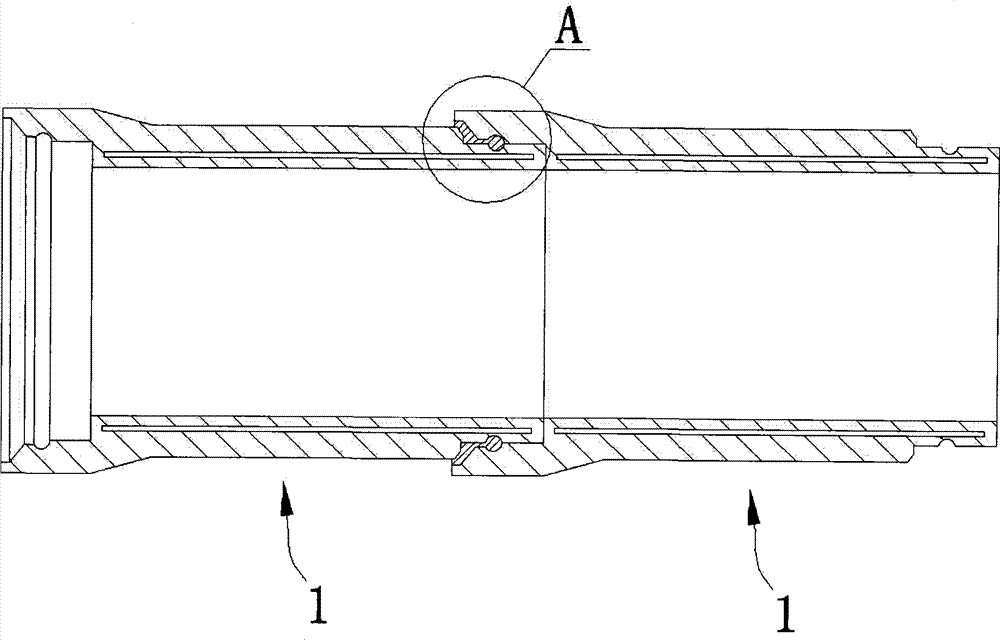

[0026] Embodiment 1: see Figure 1 to Figure 5 , a recycled concrete drainage pipe provided in this embodiment, which includes a tubular body 1 and a reinforcing rod 2 embedded in the tubular body 1 and extending along its axial direction, the outer edge of one end of the tubular body 1 is provided with The annular notch forms a socket 11, and the opening at the other end grows radially to form a socket cavity 12 compatible with the socket 11; preferably, an annular locking position 111 is provided on the socket 11, and The inserting cavity 12 is provided with an annular recess 121 corresponding to the annular clamping position 111, and the opening of the inserting cavity 12 is outwardly expanded to form a filler slope 122, and the inner wall of the insertion cavity 12 corresponds to the filler slope 122. The position between the annular recess 121 is inwardly recessed to form a feed channel 123 that can connect the annular recess 121 with the external space when the plug 11 i...

Embodiment 2

[0034] Embodiment 2: This embodiment provides a recycled concrete drainage pipe and its manufacturing method, which is basically the same as that of Embodiment 1, except that the components and weight percentages in the recycled concrete drainage pipe are different. The components and their mass percentages are as follows: 16% cement, 6% fly ash, 29% sand, and 49% recycled crushed stone.

Embodiment 3

[0035] Embodiment 3: This embodiment provides a recycled concrete drainage pipe and its manufacturing method, which is basically the same as that of Embodiment 1, except that the components and weight percentages in the recycled concrete drainage pipe are different. Its components and their mass percentages are as follows: 13% of cement, 5% of fly ash, 28% of sand, and 54% of recycled gravel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com