Small size high peak power driving method, driving circuit and driver

A high-peak, driver technology, applied in the field of small high-peak power drive methods, drive circuits and drivers, can solve the problems of multiple mechanisms, multiple functions, and small size of the driver, and achieve the effect of multiple mechanisms, multiple functions, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

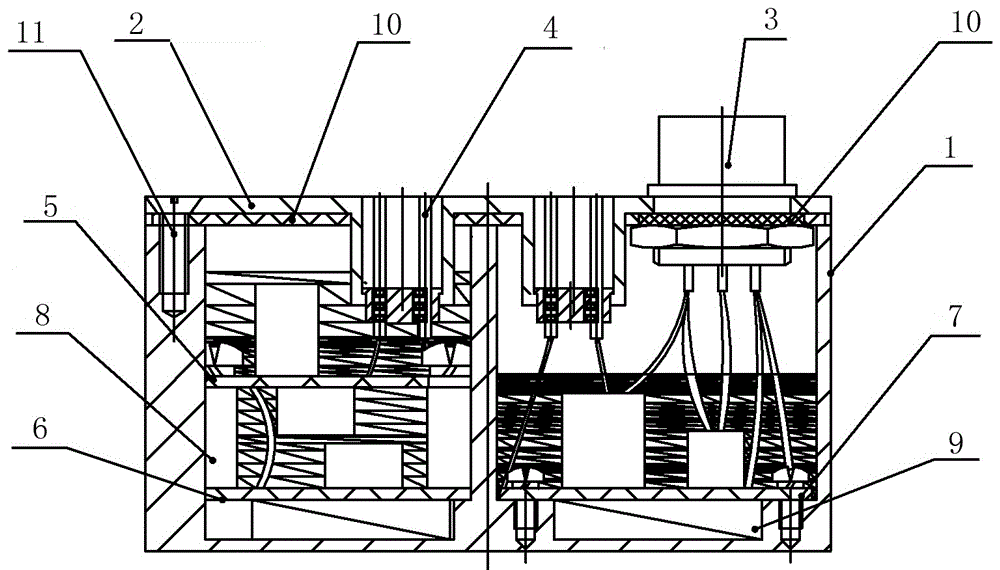

[0022] attached by figure 1 As shown, the small high-peak power driver of the present invention includes a housing, a housing cover, an electrode pin, an electrical component, and a socket. The housing is sealed with a chamber and a chamber, and a chamber is respectively fixed with circuit board 1 and circuit board 2 and filled High-temperature-resistant potting glue, the circuit board three in the second chamber is filled with high-temperature-resistant potting glue, and the shell covers of the two chambers are respectively provided with electrode pin 1 and electrode-connecting pin 2, and the shell cover and the shell are sealed by conductive rubber pads.

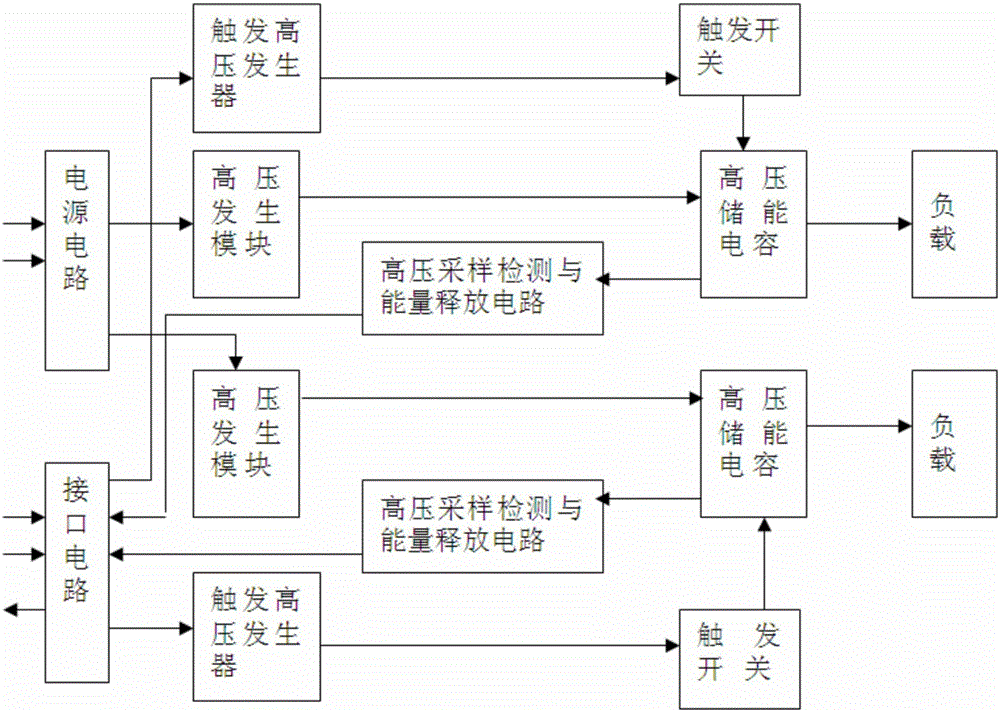

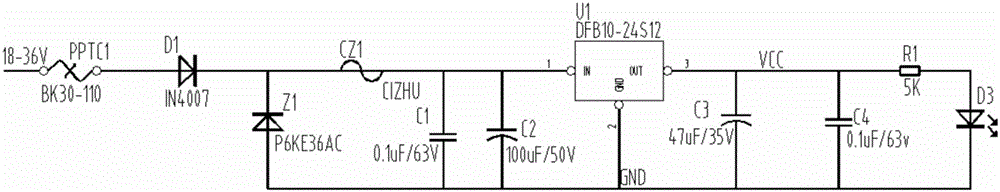

[0023] Depend on figure 1 and figure 2 As shown, the electrical components include a first circuit board, a second circuit board and a third circuit board. Among them, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com