Dehydrated instant fried rice block and manufacturing method thereof

A production method and technology for fried rice, which are applied in food preparation, food science, application and other directions, can solve problems such as poor taste, and achieve the effects of reducing packaging costs, good taste and complete nutritional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

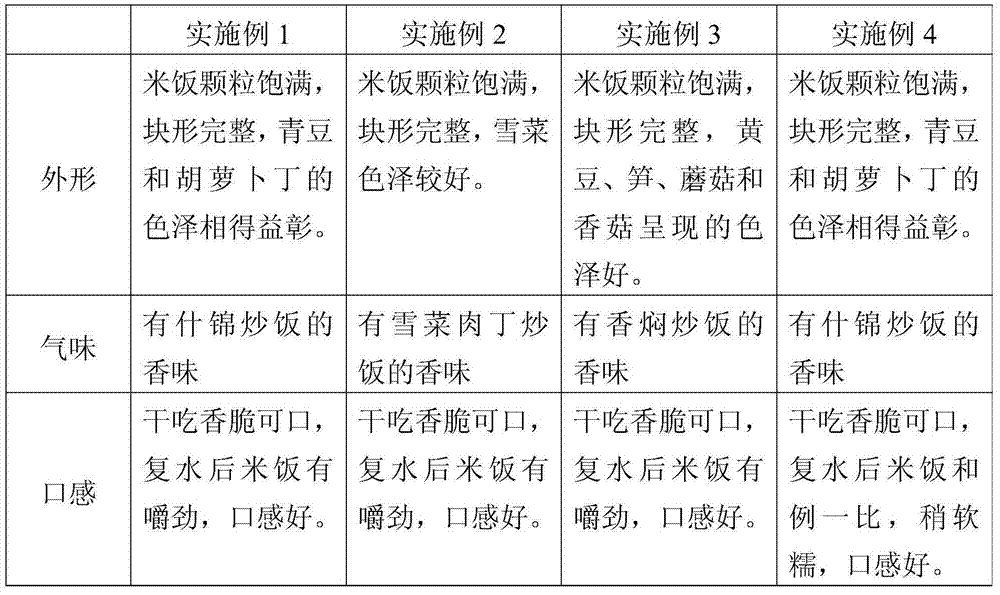

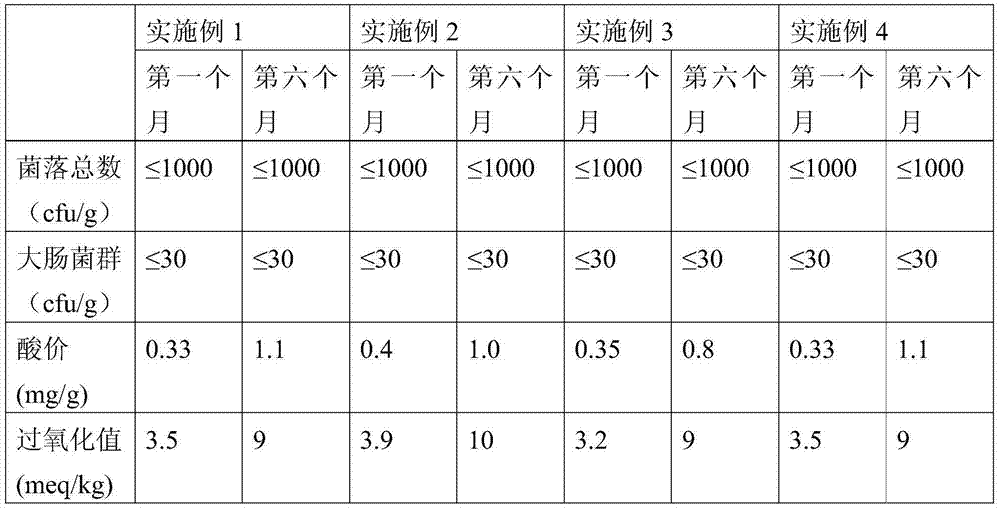

Examples

Embodiment 1

[0045] Embodiment 1, making assorted fried rice pieces

[0046] 1) Steamed rice:

[0047] ①Wash 100 parts by weight of rice with water and put it into a tray;

[0048] ② Add 120 parts by weight of water to the rice tray and soak for 30 minutes;

[0049] ③Add 5 parts by weight of shortening to the rice processed in step ②, and stir evenly;

[0050] ④Put the tray into the steamer. At this time, the water temperature in the steamer is 100°C, steam at normal pressure (1 atmosphere) for 1 hour, take it out, and set aside to get rice;

[0051] 2) Make assorted fried rice cubes

[0052] ①Preparation of main materials, auxiliary materials and additives

[0053] The composition of the main ingredients is as follows: 30 parts by weight of pork; 20 parts by weight of green beans; 4 parts by weight of diced mushrooms (dried); 24 parts by weight of diced carrots (washed);

[0054]The composition of auxiliary materials is as follows: 8 parts by weight of soybean oil; 2.65 parts by weig...

Embodiment 2

[0063] Embodiment 2, shredded pork fried rice with pickled vegetables

[0064] 1) Steamed rice

[0065] The steps are the same as step 1) in Example 1.

[0066] 2) Make fried rice cubes with pickled vegetables and shredded pork

[0067] Prepare main ingredients, auxiliary materials and additives:

[0068] The composition of the main ingredients is as follows: 40 parts by weight of pork (after precooking); 30 parts by weight of pickled cabbage (washed);

[0069] The composition of auxiliary materials is as follows: 10 parts by weight of peanut oil; 2 parts by weight of salt; 10 parts by weight of cooking wine; 6 parts by weight of minced green onion (washed); 6 parts by weight of minced ginger (washed);

[0070] The composition of the additive is as follows: 1 part by weight of shortening; 100 parts by weight of binding liquid;

[0071] Wherein 100 parts by weight of the adhesive liquid consist of: 1 part by weight of adhesive; the rest is water; the adhesive is gelatin;

...

Embodiment 3

[0073] Embodiment 3, pork edible mushroom fried rice piece

[0074] 1) Steamed rice

[0075] The steps are the same as step 1) in Example 1.

[0076] 2) Make Pork Edible Mushroom Fried Rice Cubes

[0077] Prepare main ingredients, auxiliary materials and additives:

[0078] The composition of the main ingredients is as follows: 35 parts by weight of pork (precooked); 20 parts by weight of bamboo shoots; 10 parts by weight of mushrooms (fresh); 5 parts by weight of soybeans (dry); 2.5 parts by weight of shiitake mushrooms (dry);

[0079] The composition of auxiliary materials is as follows: 10 parts by weight of soybean oil; 5 parts by weight of lard; 2.5 parts by weight of salt; 10 parts by weight of minced green onion (washed); 10 parts by weight of cooking wine; 1.25 parts by weight of soy sauce;

[0080] The composition of the additive is as follows: 1 part by weight of shortening; 100 parts by weight of binding liquid;

[0081] Wherein 100 parts by weight of the adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com