Selective catalytic reduction catalyst

A selectivity and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, catalyst activation/preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

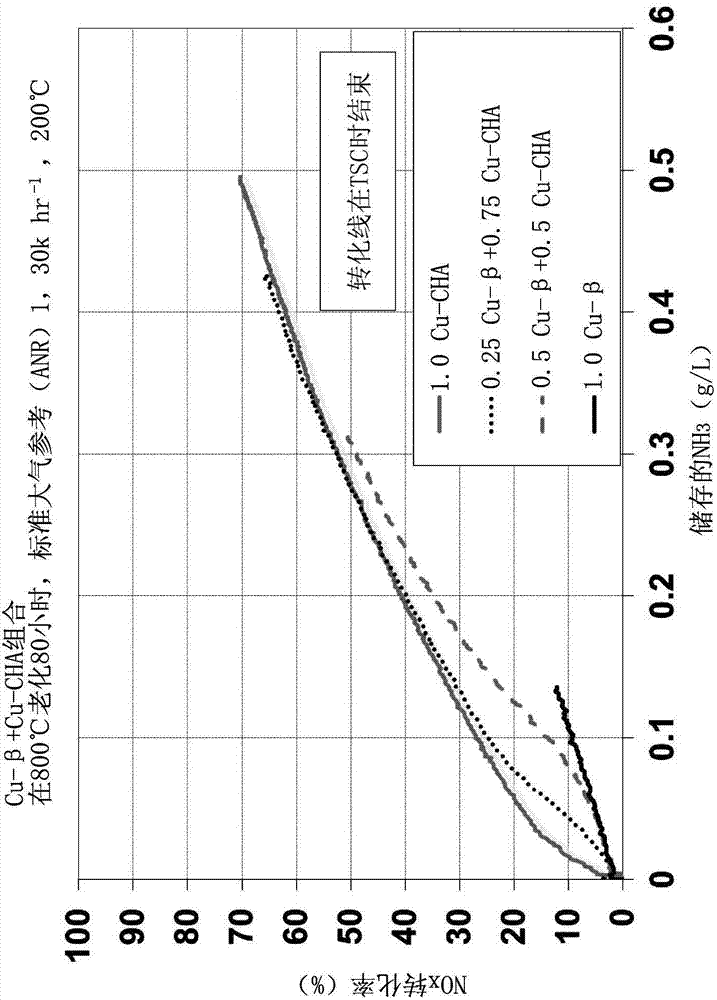

[0074] Interestingly, referring to figure 1 , by replacing a part of Cu / CHA with Cu / β, the ammonia storage capacity of the SCR system is reduced. refer to figure 1 , will be at 200°C and 30,000 h -1 NO x The conversion of is plotted as a function of the amount of ammonia stored on the catalyst in g / L. The line for conversion terminates at the point where ammonia slips through the system. The Cu / β sample itself is conversion limited and starts leaking very early. The Cu / CHA sample had the highest storage capacity and achieved the highest NO x conversion rate and leaked at the latest. Combining Cu / β with Cu / CHA reduces the ammonia storage capacity of the system and limits NO at this very low temperature x transforming ability. Without being bound by any theory, it is believed that the combination of Cu / CHA in layered form with Cu / β improves the NO x Conversion rates. The Cu / β catalyst alone stored about 0.14 g / L of NH 3 has ammonia slip at low levels of , and has a lo...

example 2

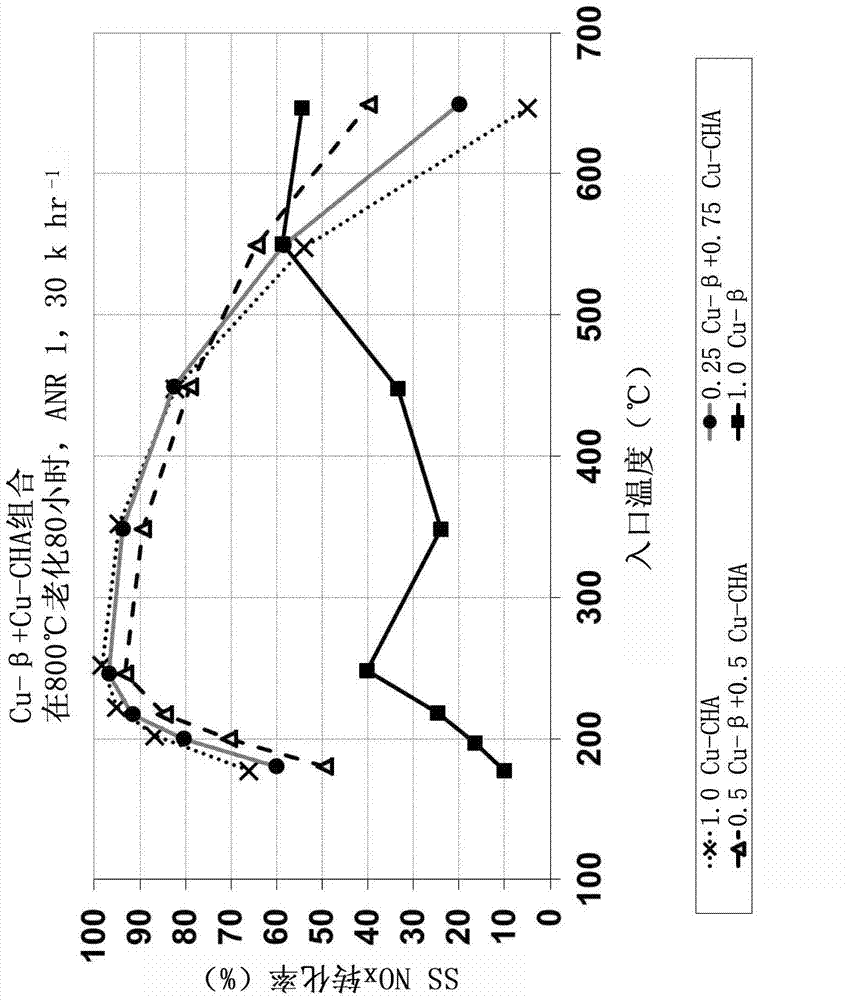

[0076] The next part of the improvement is NO at filter regeneration conditions (>500°C) x conversion rate. refer to figure 2 , experimented with different amounts of Cu / β and Cu / CHA in the system. Data were collected under steady state conditions utilizing a space velocity of 30000 / h of a flowing gas containing 14% oxygen, 5% water, 5% carbon dioxide, 350ppm NO, 350ppm NH 3 , the balance being nitrogen. Under similar conditions at 800°C (no NO x and NH 3 ) under hydrothermal aging of the catalyst for a total of 80 h. The aging is considered to represent 150,000 miles. Data shown with diamonds are for all Cu / CHA systems. High NO at 200-400°C is ideal for most driving conditions x The operating window for the conversion rate. Data shown as squares are for all Cu / β regimes. For the entire operating window, very poor conversion rates were obtained. However, the NO at 650°C x The conversion rate of is better than that of Cu / CHA sample. Replacing 1 / 4 of Cu / CHA with Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com