Regeneration method of palladium catalyst for hydrogenation reaction

A technology of hydrogenation reaction and palladium catalyst, applied in chemical instruments and methods, catalyst regeneration/reactivation, chemical/physical processes, etc., can solve problems such as inability to screen, affect palladium catalyst activity, increase regeneration equipment and regeneration procedures, etc. , to achieve the effect of optimizing the hydrogenation reaction operation, improving the regeneration effect, and improving the regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

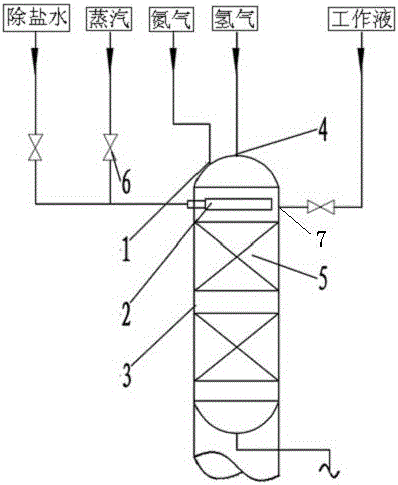

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

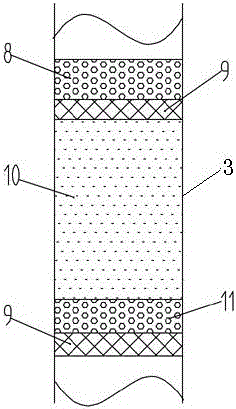

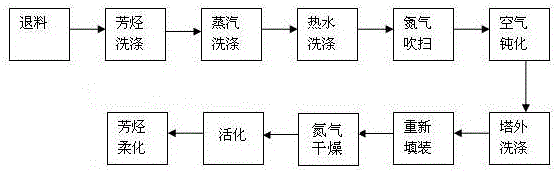

[0027] The regeneration method of palladium catalyst for hydrogenation reaction of the present invention is as figure 1 Shown, including stripping, aromatics scrubbing, steam scrubbing, hot water scrubbing, nitrogen purge, air passivation, external scrubbing, refilling, activation and aromatics softening processes. The palladium catalyst bed layer of the hydrogenation tower and each material inlet are as figure 2 As shown, the specific regeneration steps are as follows:

[0028] (1) Material removal: discharge all the working liquid of the palladium catalyst bed 5 of the hydrogenation tower 3 into the working liquid storage tank from the bottom of the tower, and the palladium catalyst bed maintains a nitrogen atmosphere and maintains a pressure of 50Kpa;

[0029] (2) Aromatic hydrocarbon washing: Aromatic hydrocarbons are passed into the hydrogenation tower through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com