A feed type eccentric adjustable automatic polishing device

An automatic polishing and eccentric technology, applied in the direction of grinding drive device, grinding/polishing equipment, grinding machine, etc., can solve the problems of unstable workpiece surface quality, large capital investment, unsuitable for the development status of small and medium-sized enterprises, etc., to get rid of man-made Factors, high degree of flexibility, good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

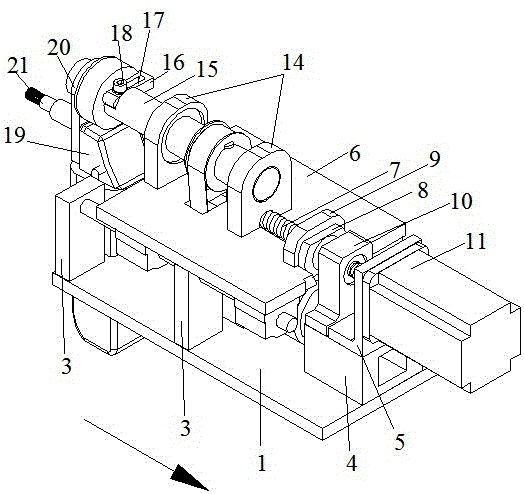

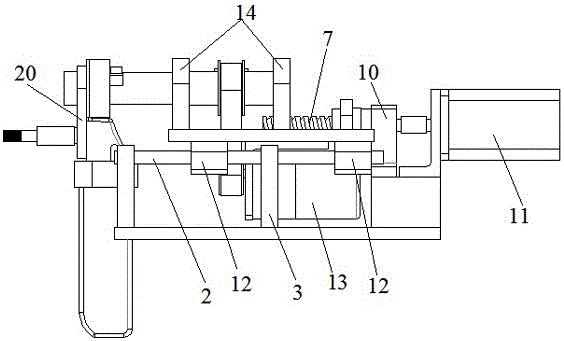

[0028] see figure 1 and figure 2 , the feed type eccentrically adjustable automatic polishing device of the present invention includes a supporting mechanism, a feeding mechanism and an eccentrically adjustable polishing mechanism arranged above the supporting mechanism.

[0029] Wherein, the support mechanism includes: a base 1, a guide rod support block 3 and a guide rod 2, the base 1 is rectangular but not limited to this shape, the guide rod support block 3 is installed on the base 1, and the guide rod 2 is connected to the guide rod support block between 3. As a specific structure, there are four guide rod support blocks 3, which are symmetrically arranged on the base 1, and are used for supporting and positioning two guide rods 2.

[0030] The feed mechanism is arranged above the support mechanism, and is used to drive the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com