Metal layer structure formed on plastic surface and surface treatment technology

A technology of surface treatment and metal layer, applied in the field of metal layer structure and its surface treatment technology, can solve the problems of poor product binding force, high content of heavy metals, environmental hazards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

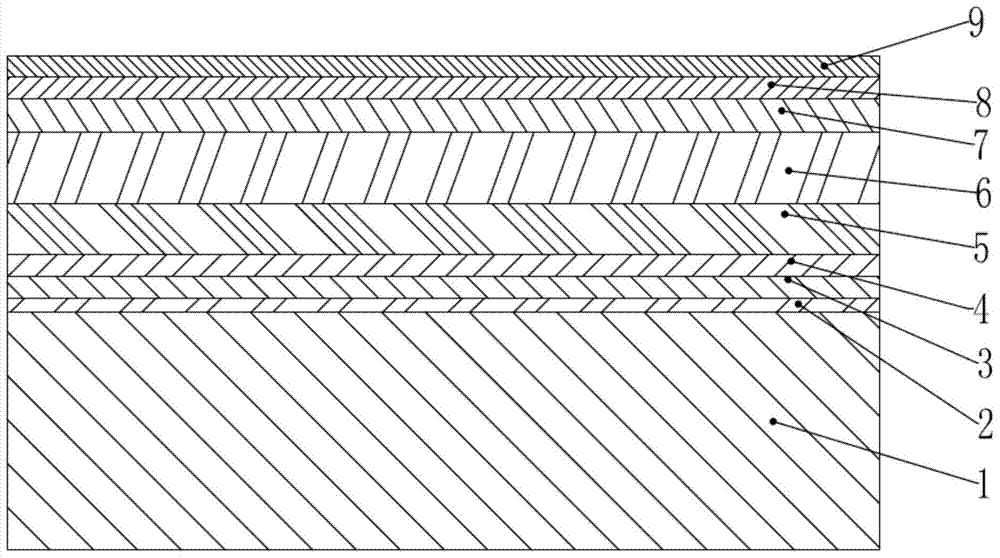

[0028] see figure 1 , the metal layer structure formed on the surface of the plastic in a preferred embodiment of the present invention includes a primer layer 2 formed on the surface of the plastic substrate 1, a metal texture layer 3 formed on the primer layer, and the metal texture layer 3 is based on ion The conductive film layer formed by sputtering plating also includes a burnt copper layer / Watt nickel layer 4 formed on the metal texture layer 3, a light copper layer 5 formed on the burnt copper layer / Watt nickel layer 4, and a light copper layer 5 formed on the light copper layer. The semi-bright nickel layer 6 on the layer 5, the light nickel layer 7 formed on the semi-bright nickel layer 6, the sealing nickel layer 8 formed on the light nickel layer 7 and the light chromium layer 9 formed on the sealing nickel layer.

[0029] The present invention also provides a surface treatment process for the metal layer structure formed on the plastic surface, comprising the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com