Semiconductor device and method for manufacturing the same

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as reduced bonding life, peeling, and reduced assembly, so as to improve adhesion and inhibit peeling. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0031]

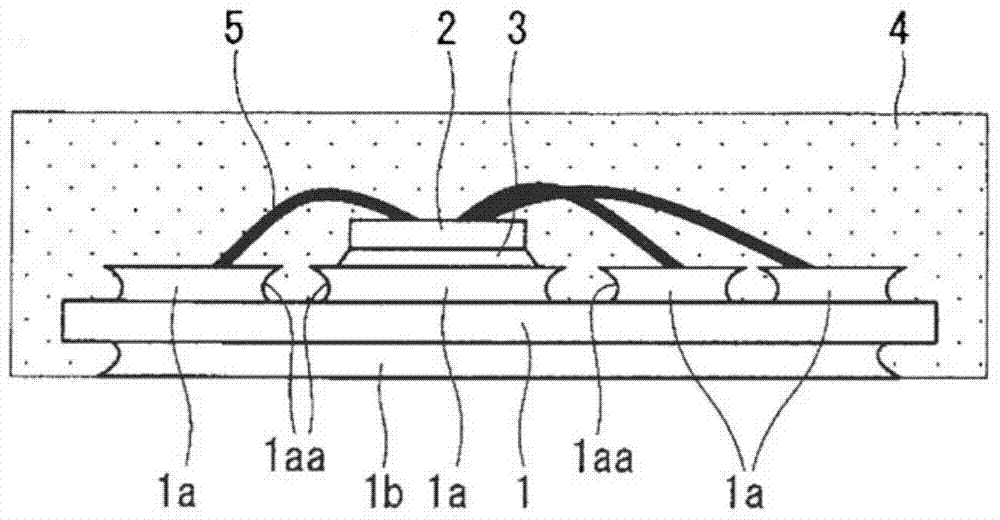

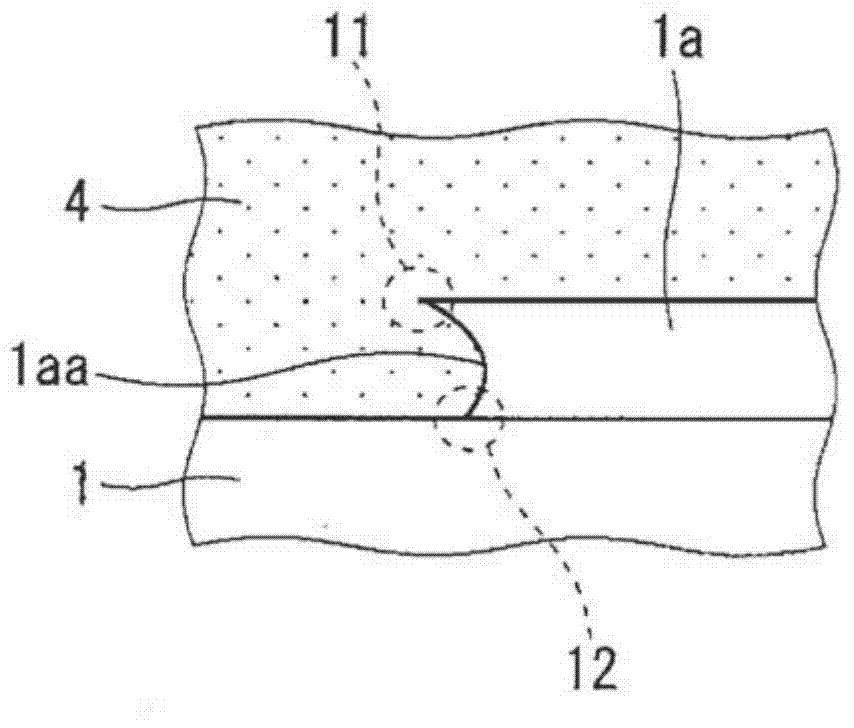

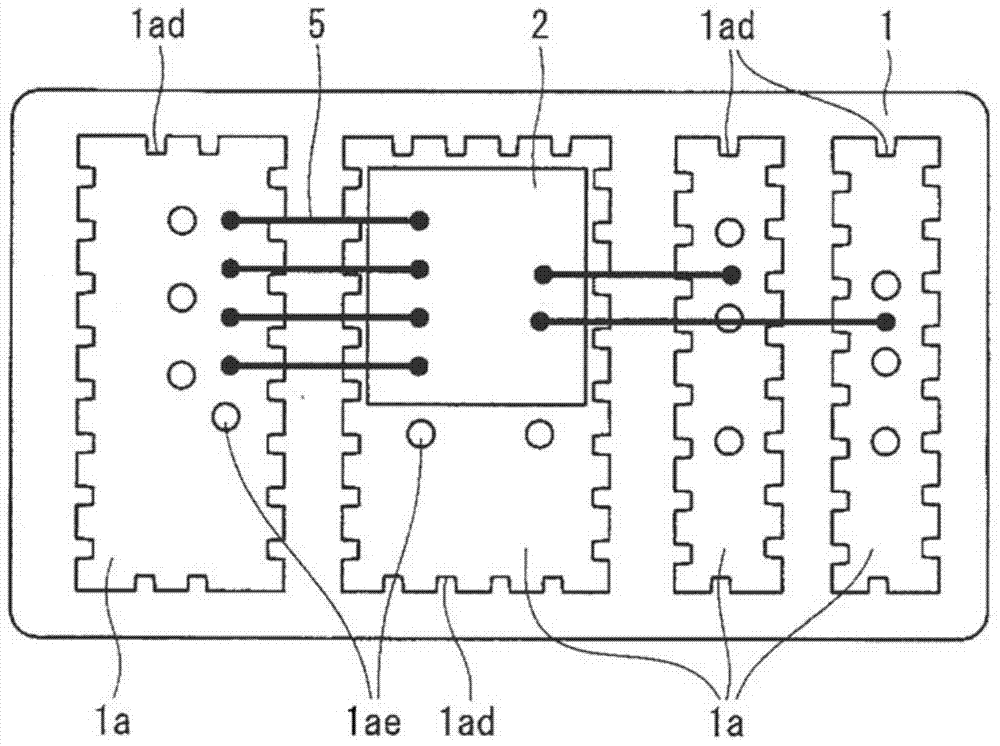

[0032] figure 1 is a cross-sectional view of the semiconductor device of the present embodiment. figure 2 It is a partial enlarged view of the cross section of the semiconductor device of this embodiment. figure 2 In more detail, yes figure 1 The cross-sectional view of the side of the circuit pattern 1a in the cross-sectional view is enlarged. also, image 3 It is a plan view of the semiconductor device of this embodiment.

[0033] In the semiconductor device of this embodiment, a plurality of circuit patterns 1 a are arranged on the surface of a ceramic substrate 1 . The semiconductor element 2 is bonded with solder 3 and mounted on the surface of at least one circuit pattern 1a.

[0034] Such as figure 1 As shown, undercut portions 1aa are formed on opposite side surfaces of circuit patterns 1a adjacent to each other. figure 2 An enlarged view showing the undercut portion 1aa. In the undercut portion 1aa, the end portion 11 of the surface of the circui...

Embodiment approach 2

[0071]

[0072] Figure 8 It is a partial enlarged view of the cross section of the semiconductor device of this embodiment. In the semiconductor device of the present embodiment, the undercut portion 1aa ( figure 2 ) similarly shaped undercuts 1ab. Figure 8 An enlarged view showing the undercut portion 1ab.

[0073] Such as Figure 8 As shown, in the undercut portion 1ab, the end portion 11 of the surface of the circuit pattern 1a protrudes outward compared with the end portion 12 of the surface of the circuit pattern 1a that is in contact with the ceramic substrate 1 . The potting resin 4 is also filled in the undercut portion 1ab. The undercut portion 1aa of Embodiment 1 is an R-shape formed by etching, but the undercut portion 1ab of this embodiment is formed by press working, so it has a linear shape. The other configurations are the same as those in Embodiment 1, and thus descriptions of the same parts are omitted.

[0074]

[0075]A method of manufacturing t...

Embodiment approach 3

[0081]

[0082] Figure 9 It is a partial enlarged view of the cross section of the semiconductor device of this embodiment. In the semiconductor device of the present embodiment, the undercut portion 1aa ( figure 2 ) similarly shaped undercuts 1af. Figure 9 An enlarged view showing the undercut portion 1af.

[0083] Such as Figure 9 As shown, in the undercut portion 1af, the end portion 11 of the surface of the circuit pattern 1a protrudes outward compared with the end portion 12 of the surface of the circuit pattern 1a that is in contact with the ceramic substrate 1 . The potting resin 4 is also filled in the undercut portion 1af.

[0084] Further, on the surface of the circuit pattern 1a, a groove 1ac is formed along the end portion 11 of the surface of the circuit pattern 1a. The distance from the end 11 of the surface of the circuit pattern 1a to the groove 1ac is less than or equal to the thickness of the circuit pattern 1a. In addition, the sealing resin 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com