Powder coating material composition and method for producing same

A powder coating and composition technology, which is applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of a large number of fluororesins and increased cost, and achieve the effect of saving process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

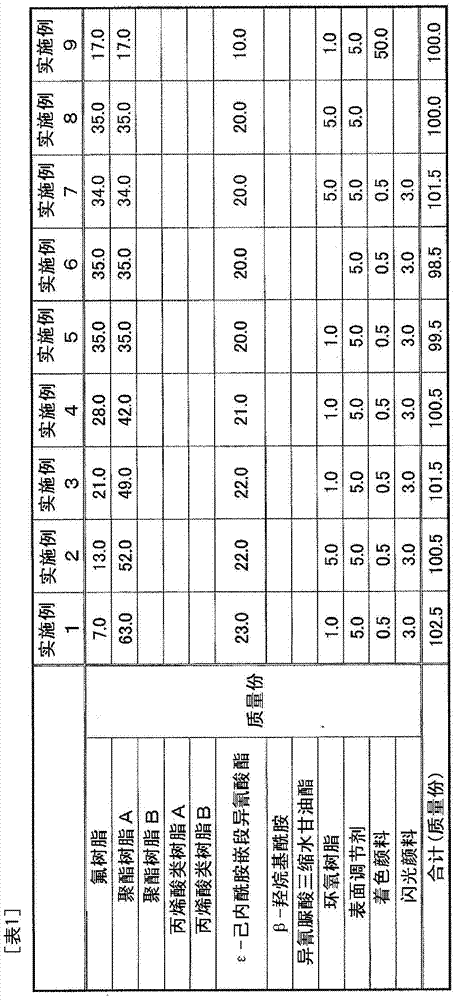

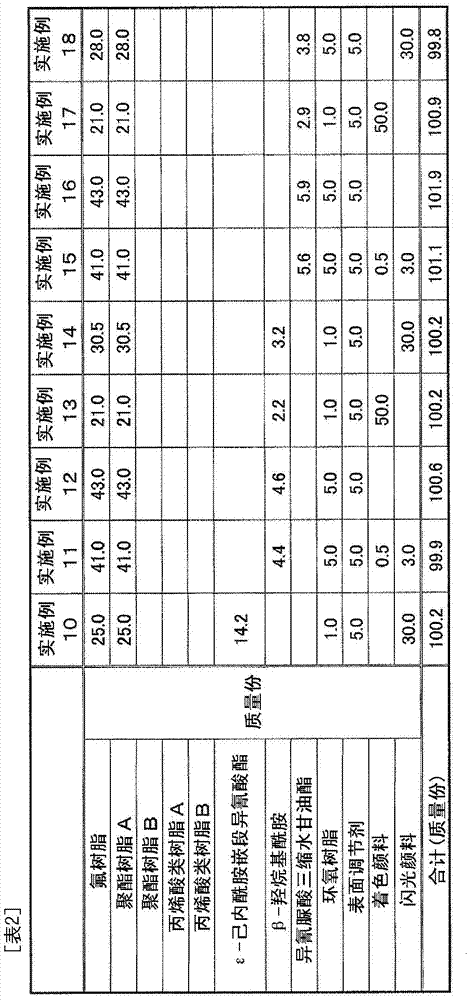

[0088] Hereinafter, the present invention will be described in more detail by way of examples and comparative examples.

[0089]

[0090] 2652 g of neopentyl glycol as an alcohol component of the polyester resin, 3966 g of isophthalic acid as a carboxylic acid component, and 4.7 g of tetra-n-butyl titanate as a reaction catalyst were charged into a mixture equipped with a stirring device, a heating device, a thermometer, In a stainless steel reaction vessel with a fractionation device and a nitrogen introduction tube, polycondensation reaction was carried out at 250° C. for 16 hours while stirring under a nitrogen atmosphere, and the reaction was terminated when a predetermined hydroxyl value was reached to obtain a polyester resin A.

[0091]

[0092] 2496 g of neopentyl glycol as an alcohol component of the polyester resin, 4233 g of isophthalic acid as a carboxylic acid component, and 4.7 g of tetra-n-butyl titanate as a reaction catalyst were charged into a mixture equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com