Cooled stationary anode for an x-ray tube

A technology of X-ray tube and anode, which is applied in the direction of X-ray tube cooling, X-ray tube anode cooling, X-ray tube cooling method, etc., to achieve the effects of enhanced cooling, good cooling, and technical problem solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

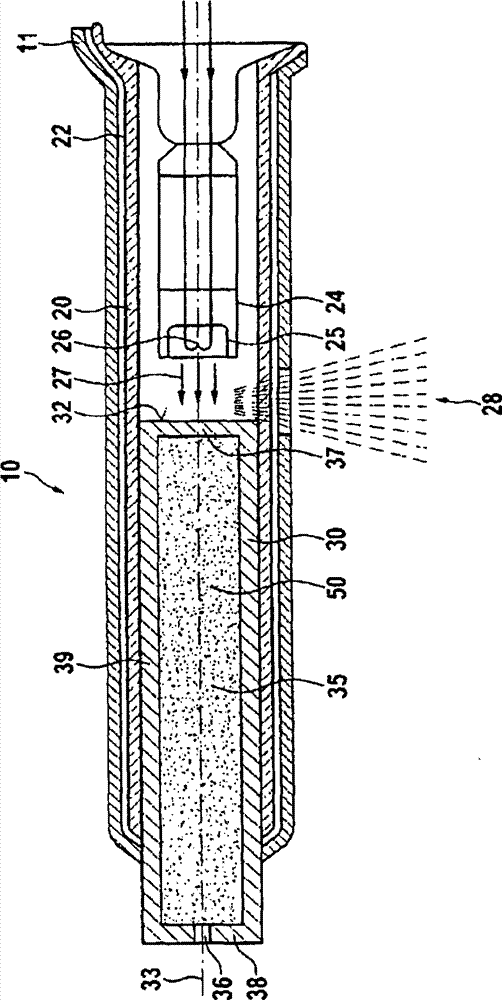

[0022] figure 1 The X-ray tube 10 in has a chamber 20, which consists of a chamber wall, eg glass. This chamber 20 is enclosed in a shell 11 , for example made of some metal. Between the chamber wall 20 and the shell 11 there is a space 22 in which the coolant circulates. Preferably, coolant circulates between space 22 and a heat exchanger (not shown).

[0023] The chamber 20 is evacuated and encloses a cathode assembly 24 having a wire cathode 26 connected to a power source. By energizing the cathode 26, the cathode 26 can be heated resulting in thermal emission of electrons.

[0024] Chamber 20 also surrounds a portion of anode 30 . The anode 30 resembles a cylindrical rod with a cylindrical axis 33 . Anode 30 has a front side facing cathode assembly 24 . On the front side of the disk 34 there is a peripheral target area 32 for the electrons 27 emitted by the cathode 26 and subsequently accelerated by the voltage between the cathode 26 and the anode 30 . The target ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com