a g-c 3 no 4 /zno/ Functional carbon adsorption material of activated carbon and preparation method thereof

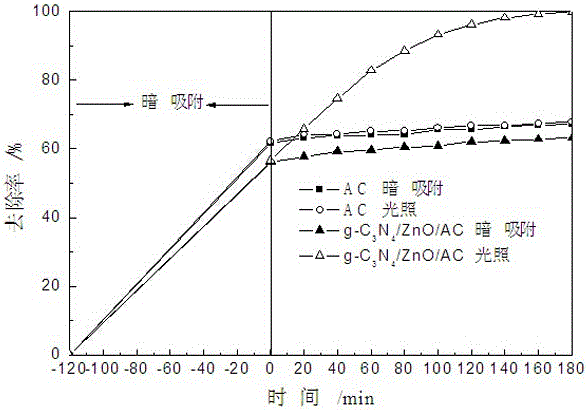

A g-c3n4, functional technology, applied in the field of preparation of functional carbon adsorption materials, can solve the problems of low quantum efficiency, large band gap, high exciton binding energy, etc., and achieve high pollutant removal ability and long service life , the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

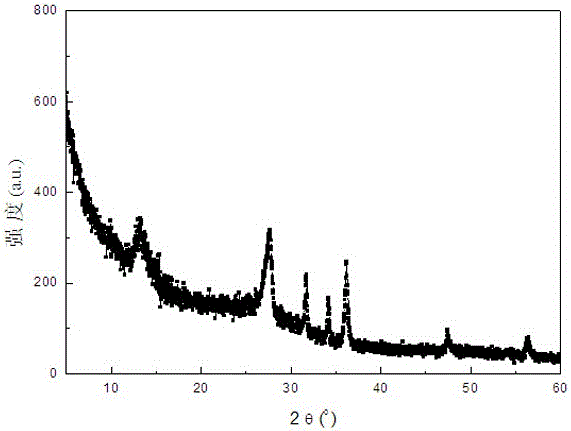

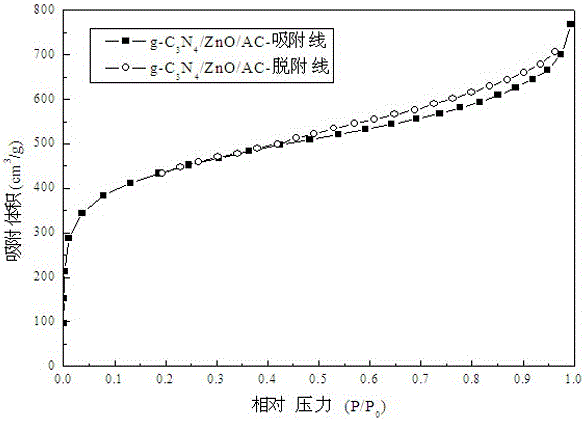

[0020] a g-C 3 N 4 The preparation method of the functional carbon adsorption material of / ZnO / activated carbon comprises the following steps:

[0021] (1) Crushing, screening and drying wood or bamboo raw materials;

[0022] (2) Take 10g of the dried raw material and heat it up to 400°C at a rate of 5°C / min under the protection of high-purity nitrogen, keep it warm for 2h, and cool it down to room temperature naturally;

[0023] (3) Add 1g of zinc acetate to 50 mL of distilled water under stirring conditions, and react for 20 minutes, then add 1.5g of melamine, continue to stir and react for 30 minutes, and fully mix with the material prepared in step (2), dip for 24 hours, 80 °C down drying;

[0024] (4) The material prepared in step (3) was raised from room temperature to 500°C at a rate of 10°C / min under the protection of high-purity nitrogen, kept at a constant temperature for 2 hours, and then raised to 530°C at a rate of 0.2°C / min. And keep the temperature for 5h, a...

Embodiment 2

[0026] a g-C 3 N 4 The preparation method of the functional carbon adsorption material of / ZnO / activated carbon comprises the following steps:

[0027] (1) Crushing, screening and drying wood or bamboo raw materials;

[0028] (2) Take 10g of the dried raw material and heat it up to 420°C at a rate of 5°C / min under the protection of high-purity nitrogen, keep it warm for 1h, and cool it down to room temperature naturally;

[0029] (3) Add 3g of zinc acetate to 50 mL of distilled water under stirring conditions, and react for 20 minutes, then add 5g of melamine, continue stirring and reacting for 30 minutes. drying;

[0030] (4) The material prepared in step (3) was raised from room temperature to 500°C at a rate of 10°C / min under the protection of high-purity nitrogen, kept at a constant temperature for 2 hours, and then raised to 530°C at a rate of 0.2°C / min. And keep the temperature for 5h, and cool down to room temperature naturally to get the g-C 3 N 4 / ZnO / activated ...

Embodiment 3

[0032] a g-C 3 N 4 The preparation method of the functional carbon adsorption material of / ZnO / activated carbon comprises the following steps:

[0033] (1) Crushing, screening and drying wood or bamboo raw materials;

[0034] (2) Take 10g of the dried raw material and heat it up to 450°C at a rate of 5°C / min under the protection of high-purity nitrogen, keep it warm for 1.5h, and cool it down to room temperature naturally;

[0035](3) Add 2g of zinc acetate to 50 mL of distilled water under stirring conditions, and react for 20 minutes, then add 3g of melamine, continue stirring and reacting for 30 minutes, fully mix with the material prepared in step (2), dip for 24 hours, at 80 drying;

[0036] (4) The material prepared in step (3) was raised from room temperature to 500°C at a rate of 10°C / min under the protection of high-purity nitrogen, kept at a constant temperature for 2 hours, and then raised to 530°C at a rate of 0.2°C / min. And keep the temperature for 5h, and coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com