Aerogel material and preparation method and application thereof

An aerogel and sustained-release material technology, which is applied in the field of aerogel materials and its preparation, can solve the problems of uneven release speed, insufficient sustained-release time, and inability of consumers to add mosquito repellents at will, and achieves liquid release. Uniform speed, excellent sustained release performance, no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh raw materials: Weigh 33 grams of hexamethylene diisocyanate trimer (Desmodur N3300A), 94 ml of polar solvent acetone, 3.53 ml of deionized water, and 0.6% by mass of alkali Sex catalyst triethylamine (Triethylamine);

[0045] (2) Mixing: First, mix the hexamethylene diisocyanate trimer and acetone weighed in step (1) evenly, then add deionized water to the mixed solution, then add the basic catalyst triethylamine, and mix evenly;

[0046] (3) Post-processing: Stir the mixture obtained in step (2) uniformly with a magnetic bar stirrer for 10 minutes, then let it stand for 1 hour to form an airgel, and inject the airgel into a polypropylene plastic mold to form and dry An airgel material is obtained.

[0047] The density of the airgel material prepared in Example 1 is about: 0.33g / cm 3 , is a high-density airgel material.

Embodiment 2

[0049] (1) Weigh raw materials: Weigh 17 grams of hexamethylene diisocyanate trimer (Desmodur N3300A), 94 ml of polar solvent acetone, 1.5 ml of deionized water, and 0.2% by mass of alkali Sex catalyst triethylamine (Triethylamine);

[0050] (2) Mixing: First, mix the hexamethylene diisocyanate trimer and acetone weighed in step (1) evenly, then add deionized water to the mixed solution, then add the basic catalyst triethylamine, and mix evenly;

[0051] (3) Post-processing: Stir the mixture obtained in step (2) evenly for 10 minutes with a magnetic bar stirrer, and then let it stand for 3 hours to form an airgel, and inject the airgel into a polypropylene plastic mold to form and dry An airgel material is obtained.

[0052] The density of the airgel material prepared in embodiment 2 is about: 0.17g / cm 3 , is a medium-density airgel material.

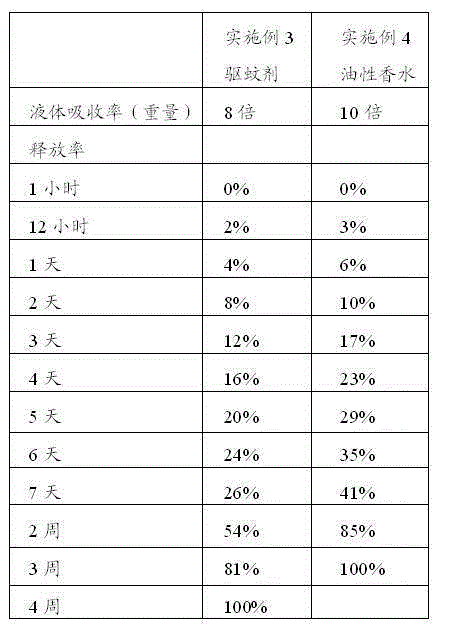

Embodiment 3

[0054] (1) Weigh raw materials: Weigh 7 grams of hexamethylene diisocyanate trimer (Desmodur N3300A), 94 ml of polar solvent acetonitrile, 0.2 ml of deionized water, and 0.05% by mass of alkali Sex catalyst triethylamine (Triethylamine);

[0055] (2) Mixing: First, mix the hexamethylene diisocyanate trimer and acetone weighed in step (1) evenly, then add deionized water to the mixed solution, then add the basic catalyst triethylamine, and mix evenly;

[0056] (3) Post-processing: Stir the mixture obtained in step (2) evenly for 10 minutes with a magnetic bar stirrer, and then let it stand for 12 hours to form an airgel, and inject the airgel into a polypropylene plastic mold to form and dry An airgel material is obtained.

[0057] The density of the airgel material prepared in embodiment 3 is about: 0.07g / cm 3 , is a low-density airgel material.

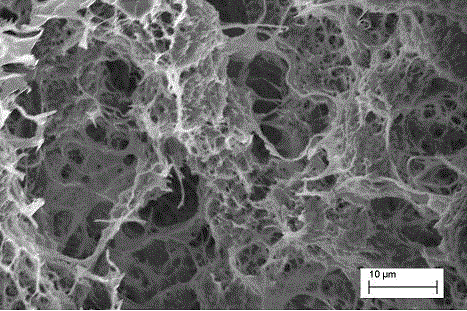

[0058] figure 1 It is the electron micrograph of the airgel material prepared in Example 1.

[0059] Such as figure 1 Shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com