Inorganic binder activated carbon rod and manufacturing process thereof

An inorganic binder and activated carbon technology, applied in the field of activated carbon carbon rods, can solve the problems of low water purification performance and water passage function, falling off and mixing into drinking water discharge, etc., to improve water purification performance, water passage, and water purification performance High and prolong service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

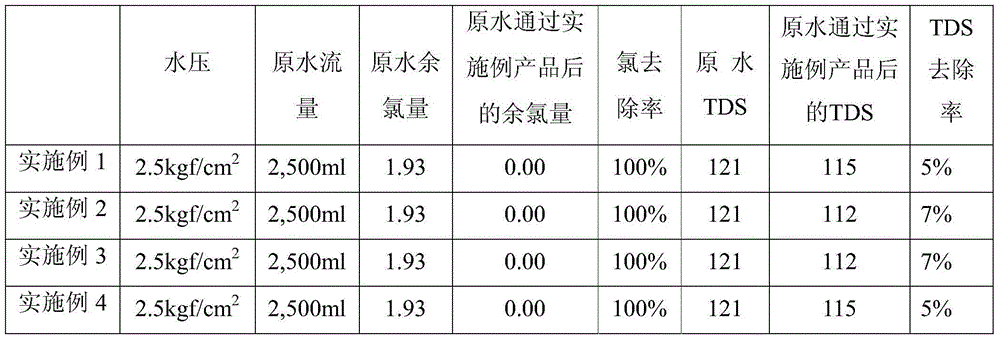

Examples

Embodiment 1

[0037] An inorganic binder activated carbon carbon rod is made from the following raw materials by weight: 80% of activated carbon and 20% of inorganic binder.

[0038] Among them: the inorganic binder is composed of kaolin, clay and loess in a mass ratio of 6:4:4.

[0039] The preparation method of the described inorganic binder activated carbon carbon rod comprises the following steps:

[0040] (1) Wet stirring process of raw materials

[0041] Put the 100-mesh activated carbon and the inorganic binder into the mixer, then pour in water, the water accounts for 60% of the total weight of the activated carbon and the inorganic binder, and fully stir to obtain the activated carbon slurry;

[0042] (2) Compression drying and aging process

[0043] The activated carbon pulp obtained in step (1) is put into a mold made of non-woven fabrics, compressed to remove the moisture therein, and then dried at 23° C. for 2.5 days to be an activated carbon pulp with a moisture content of 3...

Embodiment 2

[0054] An inorganic binder activated carbon carbon rod is made from the following raw materials by weight: 70% of activated carbon and 30% of inorganic binder.

[0055] Among them: the inorganic binder is composed of kaolin, clay and loess in a mass ratio of 5:3:3.

[0056] The preparation method of the described inorganic binder activated carbon carbon rod comprises the following steps:

[0057] (1) Wet stirring process of raw materials

[0058] Put the 325-mesh activated carbon and the inorganic binder into the mixer, then pour in water, the water accounts for 70% of the total weight of the activated carbon and the inorganic binder, and fully stir to obtain the activated carbon slurry;

[0059] (2) Compression drying and aging process

[0060] The activated carbon pulp obtained in step (1) is put into a mold made of non-woven fabrics, compressed to remove the moisture therein, and then dried at 20° C. for 3 days to be an activated carbon pulp with a moisture content of 40%...

Embodiment 3

[0071] An inorganic binder activated carbon carbon rod is made from the following raw materials by weight: 90% of activated carbon and 10% of inorganic binder.

[0072]Among them: the inorganic binder is composed of kaolin, clay and loess in a mass ratio of 10:5:5.

[0073] The preparation method of the described inorganic binder activated carbon carbon rod comprises the following steps:

[0074] (1) Wet stirring process of raw materials

[0075] Put the 10-mesh activated carbon and the inorganic binder into the mixer, then pour in water, the water accounts for 65% of the total weight of the activated carbon and the inorganic binder, and fully stir to obtain the activated carbon slurry;

[0076] (2) Compression drying and aging process

[0077] The activated carbon pulp obtained in step (1) is put into a mold made of non-woven fabrics, compressed to remove the moisture therein, and then dried at 25° C. for 2 days to be an activated carbon pulp with a moisture content of 25%;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com