Method for preparing self-healing composite material by employing electrospinning method

A composite material and electrospinning technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as complex chemical reactions, large microcapsule or fiber size, difficult operation, etc., and achieve uniform diameter distribution and complete fiber structure , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

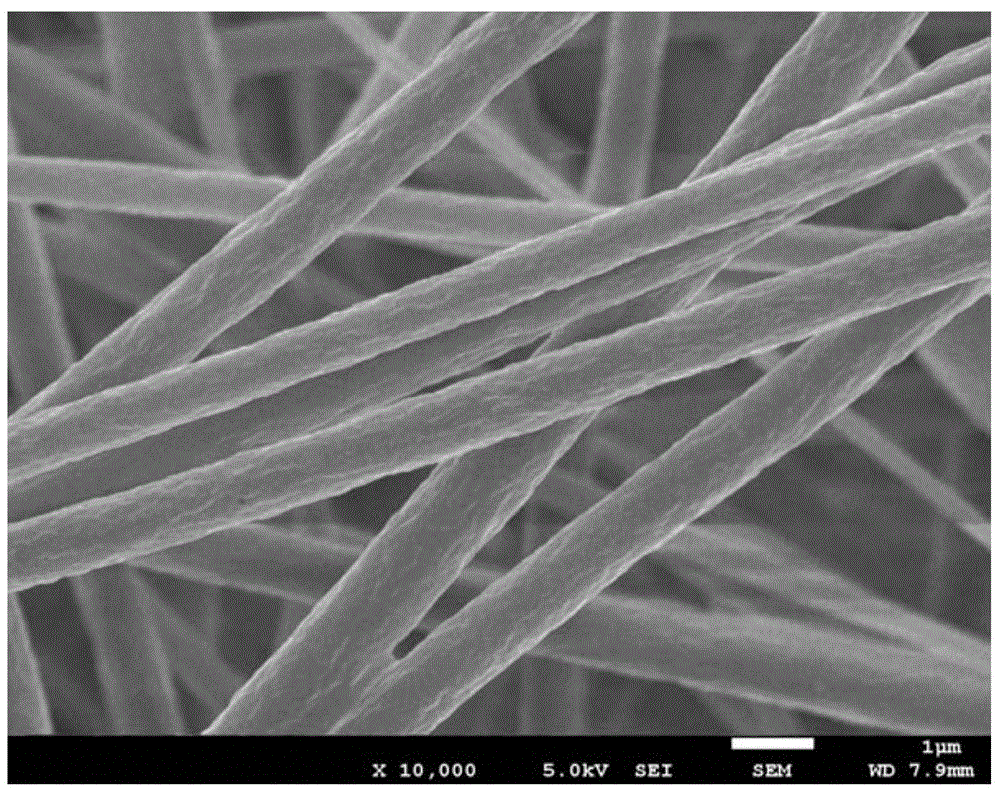

[0029] Embodiment 1, the preparation of self-healing composite fiber 1

[0030] 1) Add 5 g of polystyrene (molecular weight: 250,000) into 20 g of DMF, and mechanically stir until the solution is transparent, thereby obtaining a homogeneous solution with a mass ratio of polystyrene to DMF of 5 / 20. The liquid epoxy resin (epoxy resin RIM135) that takes by weighing 3g joins in the polystyrene solution of above-mentioned gained, mechanically stirs, obtains the mixed solution of polystyrene and RIM135, i.e. electrospinning solution; Wherein the RIM135 and The mass ratio of polystyrene is about 36 / 60;

[0031] The prepared blend solution of RIM135 and polystyrene was filled into the liquid storage device, a spinning voltage of 20KV was applied between the spinning needle and the receiving device, and the spinning distance between the spinning needle and the receiving aluminum foil was controlled to be 13cm. The flow rate of the blended solution of the polymer and the healing agent w...

Embodiment 2

[0039] Embodiment 2, the preparation of self-healing composite fiber 2

[0040] 1) Add 5 g of polyacrylonitrile (molecular weight: 150,000) into 95 g of DMF, and mechanically stir until the solution is transparent, thereby obtaining a homogeneous solution with a mass ratio of polyacrylonitrile to DMF of 5 / 95. Weigh 3g of p-tert-butylphenyl 1-(2,3-epoxy) propyl ether and add it to the polyacrylonitrile solution obtained above, and stir mechanically to obtain polyacrylonitrile and p-tert-butylphenyl 1 -(2,3-epoxy) propyl ether mixed solution, namely to get the electrospinning solution; wherein the added p-tert-butylphenyl 1-(2,3-epoxy) propyl ether and polyacrylonitrile The mass ratio is 36 / 60.

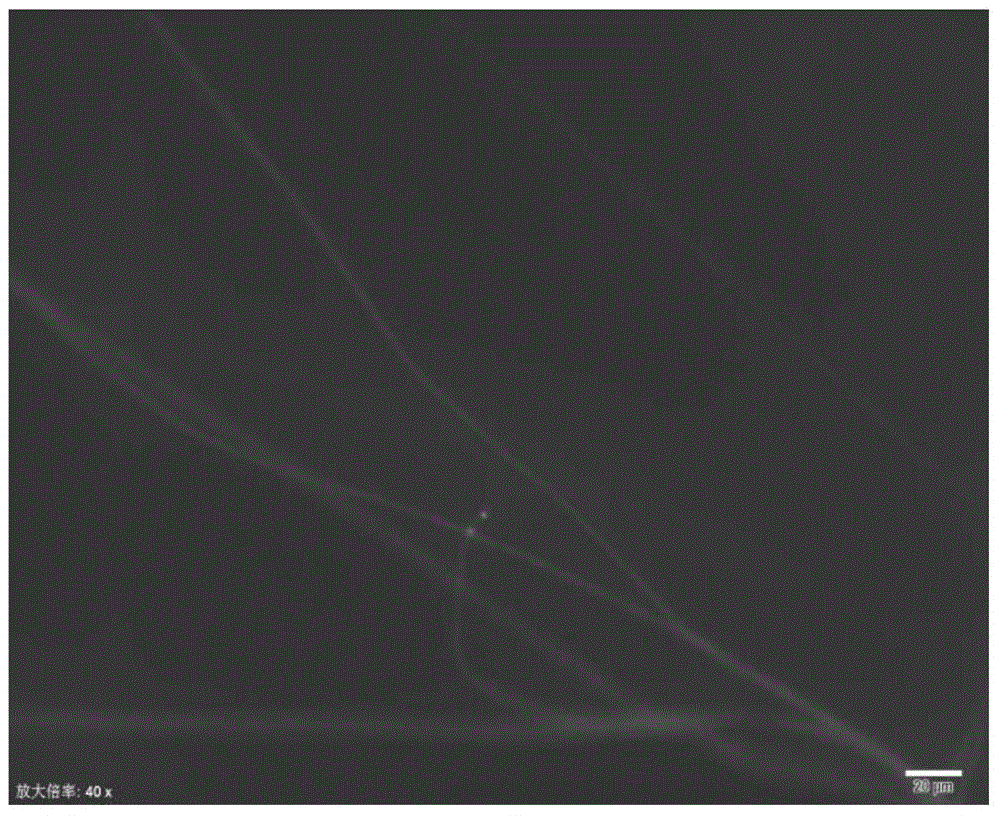

[0041] The blended solution of polyacrylonitrile and p-tert-butylphenyl 1-(2,3-epoxy) propyl ether is loaded into the liquid storage device, and 20KV spinning is applied between the spinning needle and the receiving device. Voltage, control the spinning distance between the spinning n...

Embodiment 3

[0045] Embodiment 3, preparation of self-healing composite fiber 3

[0046] 1) Add 5 g of polystyrene (molecular weight: 250,000) into 12 g of DMF, and stir mechanically until the solution is transparent, thereby obtaining a homogeneous solution with a mass ratio of polystyrene to DMF of 5 / 12. Weigh 3g of p-tert-butylphenyl 1-(2,3-epoxy) propyl ether and add it to the polystyrene solution obtained above, and stir mechanically to obtain polystyrene and p-tert-butylphenyl 1 -(2,3-epoxy) propyl ether mixed solution, which is the electrospinning solution; p-tert-butylphenyl 1-(2,3-epoxy) propyl ether and polystyrene added The mass ratio is 36 / 60;

[0047] The blended spinning solution of the prepared polystyrene and p-tert-butylphenyl 1-(2,3-epoxy) propyl ether is loaded into the liquid storage device, and 20KV spinning is applied between the spinning needle and the receiving device. Filament voltage, control the spinning distance between the spinning needle and the receiving al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com