Unpowered microbubble water device

A micro-bubble and power technology, applied in flotation water/sewage treatment, dissolution, mixer, etc., can solve problems such as application limitation, increase in device volume, noise, etc., to achieve increased mass transfer coefficient and low cost , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

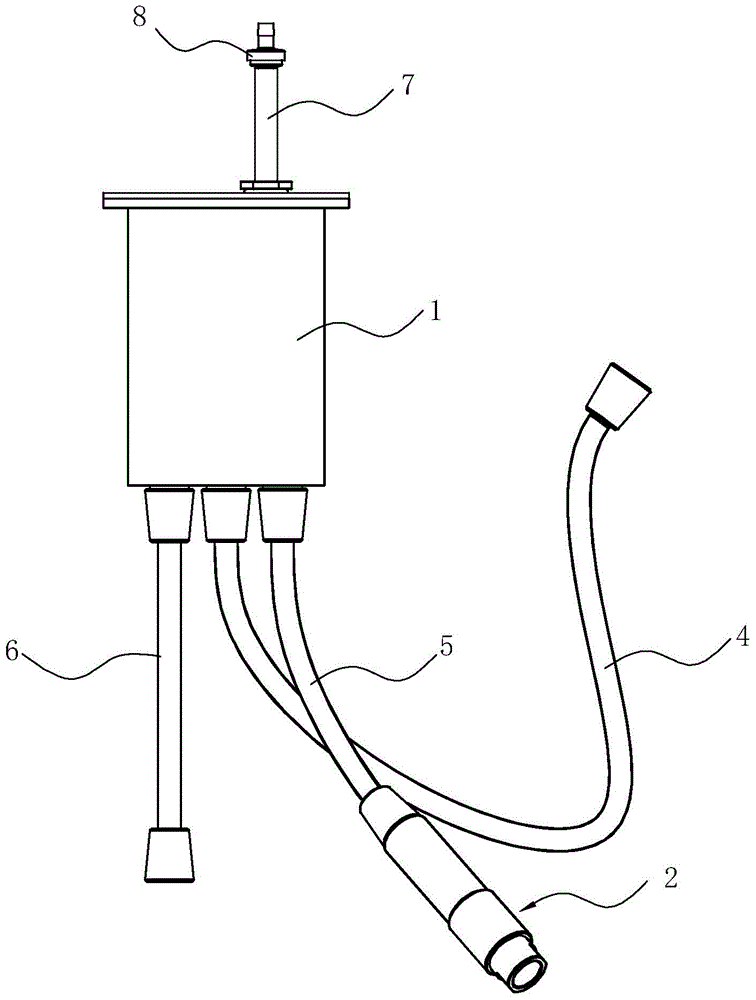

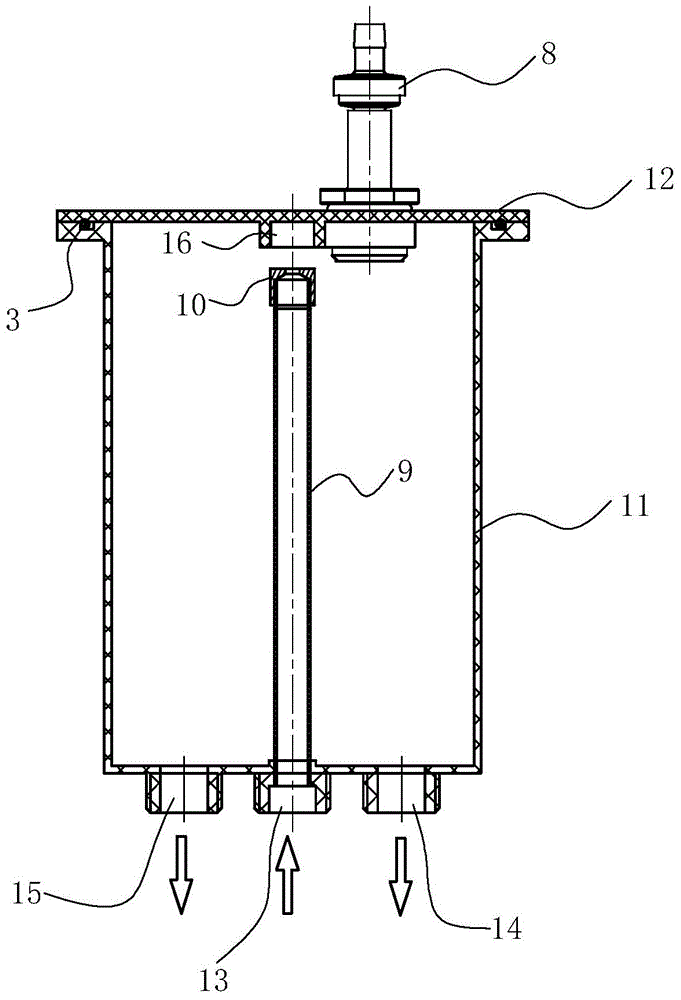

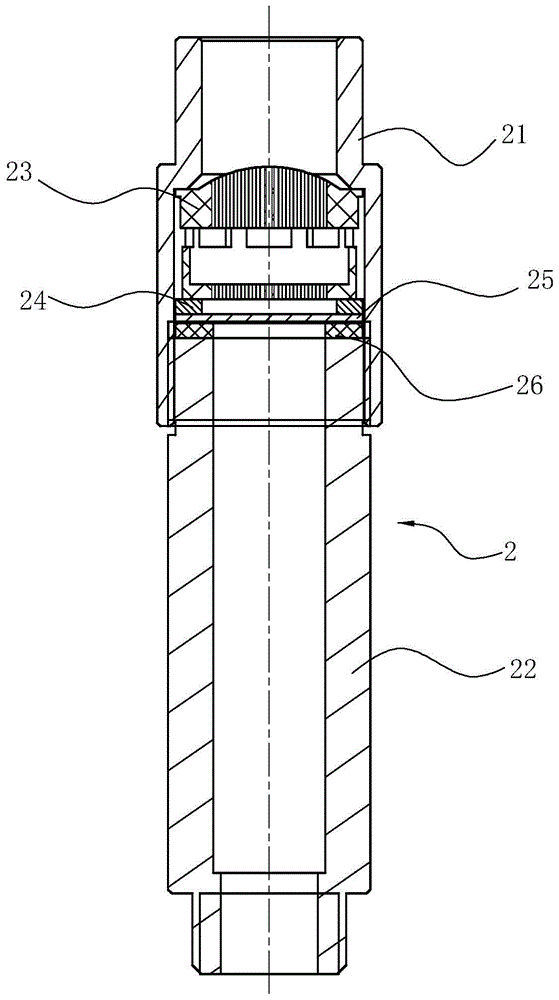

[0021] Such as Figure 1 to Figure 4 As shown, there is no compression pump in this unpowered microbubble water device, and it includes a dissolved air tank 1 and a dissolved air releaser 2, wherein the dissolved air tank 1 has a tank body 11 and an upper cover 12 combined, and in both A sealing ring 3 is installed on the contact surface to form a closed cavity in the dissolved air tank. The bottom of the dissolved gas tank is provided with a water inlet 13, a water outlet 14 and a water outlet 15. The water inlet is connected to the tap water pipe with a pressure greater than 0.15MPA through the water inlet pipe 4, and the water outlet is connected to the dissolved air release device 2 through the water outlet pipe 5. The water inlet hole is connected, the drain is connected with a drain hose 6, and an air inlet pipe 7 is installed on the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com