Method for preparing yttrium oxide-based transparent ceramic employing two-step sintering method

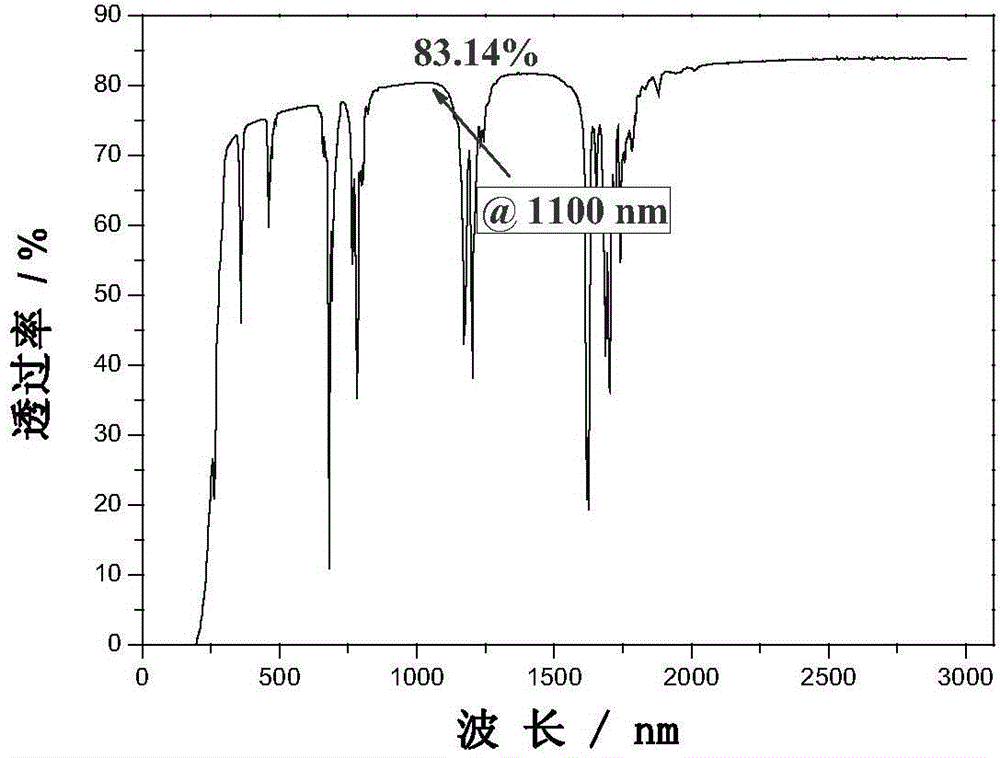

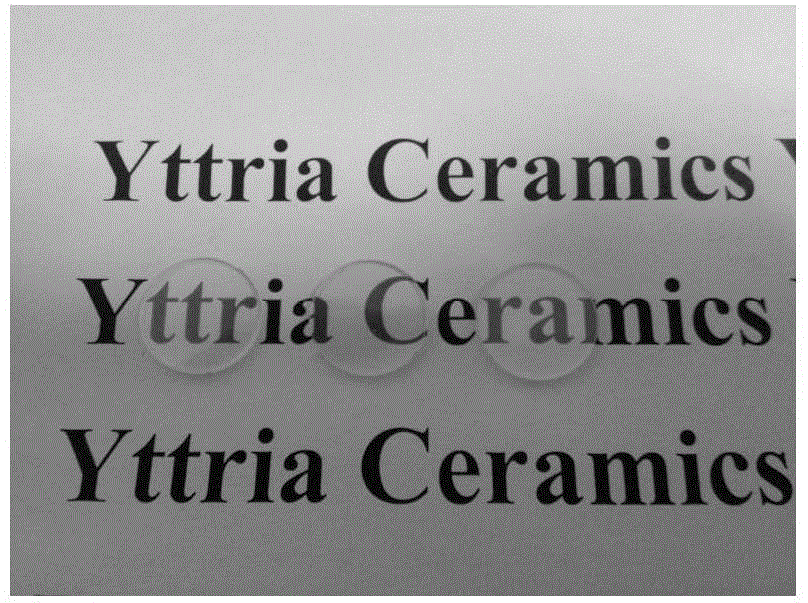

A technology of transparent ceramics and yttrium oxide, which is applied in the field of preparing yttrium oxide-based transparent ceramics by two-step sintering, can solve the problems of low transmittance of transparent ceramics, poor mechanical properties of transparent ceramics, and high cost of preparation process, and achieves suppression of grain boundaries. The effect of migration, elimination of tiny pores, and improvement of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 # (undoped, Y 2 o 3 ):

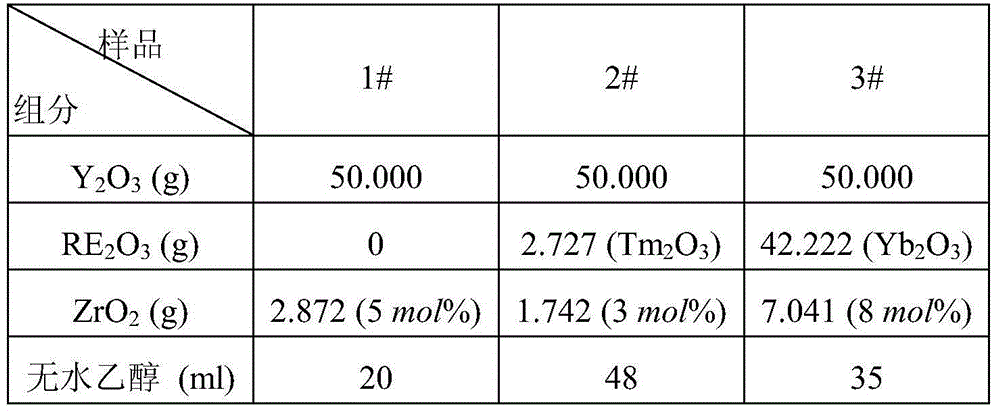

[0027] Composition as in Table 1 1 # Shown, specific preparation method comprises the following steps:

[0028] ①Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into a nylon ball mill jar, add 150g of high-purity zirconia balls, and add sintering aids and absolute ethanol; ball mill and mix on a planetary ball mill For 18 hours, the rotation speed is 100r / min, and the slurry used for two-step sintering is obtained; the slurry after ball milling is dried in a drying oven; then, it is sieved with 60 meshes, and the sieved powder is calcined in a muffle furnace at 600°C 8h;

[0029] ②Using a hydraulic press and cold isostatic pressing to shape the powder obtained in step ①. The molding conditions are: pre-pressing pressure 15MPa, cold isostatic pressing pressure 250MPa, cold waiting time 3min, calcined at 600°C for 8h in a muffle furnace to obtain Y 2 o 3 Biscuit;

[0030] ...

Embodiment 2

[0031] Example 2 # (3mol%Tm:Y 2 o 3 ,(Y 0.97 T m 0.03 ) 2 o 3 ):

[0032] Composition as in Table 1 2 # Shown, specific preparation method comprises the following steps:

[0033] ①Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into a nylon ball mill jar, add 150g of high-purity zirconia balls, and add sintering aids and absolute ethanol; ball mill and mix on a planetary ball mill 10 hours at a speed of 180r / min to obtain the slurry used for two-step sintering; the slurry after ball milling was dried in a drying oven; then sieved with 200 meshes, and the sieved powder was calcined in a muffle furnace at 800°C 5h;

[0034] ②Using a hydraulic press and cold isostatic pressing to shape the powder obtained in step ①. The molding conditions are: pre-pressing pressure 18MPa, cold isostatic pressing pressure 200MPa, cold waiting time 5min, calcined at 800℃ for 5h in a muffle furnace to obtain Y 2 o 3 Biscuit;

[00...

Embodiment 3

[0036] Example 3 # (30mol%Yb:Y 2 o 3 ,(Y 0.7 Yb 0.3 ) 2 o 3 ):

[0037] Composition as in Table 1 3 # Shown, specific preparation method comprises the following steps:

[0038] ① Weigh the raw materials according to the composition in Table 1. First, put the oxide raw material powder into a nylon ball mill jar, add 150g of high-purity zirconia balls, and add sintering aids and absolute ethanol to prepare the slurry; The upper ball mill was mixed for 15 hours at a speed of 140r / min to obtain the slurry used for two-step sintering; the slurry after ball milling was dried in a drying oven; Calcination at 1000℃ for 3h;

[0039] ②Using a hydraulic press and cold isostatic pressing to shape the powder obtained in step ①. The molding conditions are: pre-pressing pressure 30MPa, cold isostatic pressing pressure 150MPa, cold waiting time 10min, calcined at 1000℃ for 3h in a muffle furnace to obtain Y 2 o 3 Biscuit;

[0040] ③ Sinter the biscuit obtained in step ② in vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com