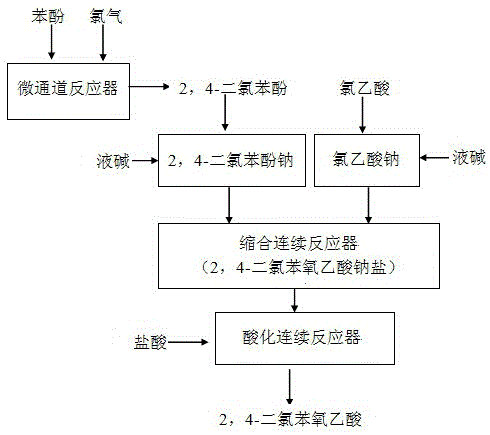

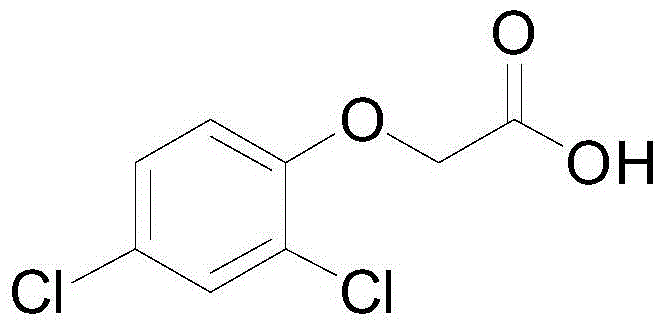

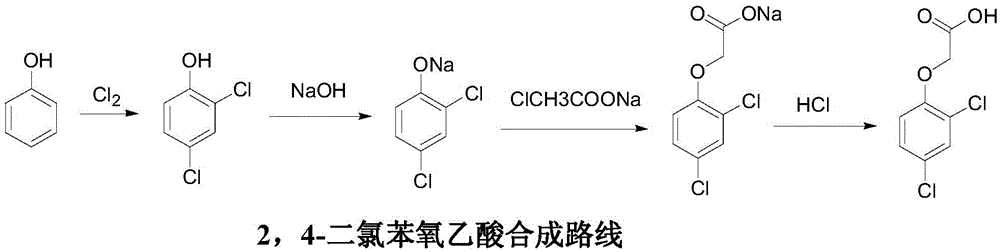

Method for continuous production of herbicide 2,4-dichlorophenoxyacetic acid

A technology of dichlorophenoxyacetic acid and herbicide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as floating, increase of human operation factors, and the influence of chlorinated product quality, and achieve industrialization. The effect of production, emission reduction, safe and continuous industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A microchannel reactor is used to continuously feed phenol (94kg / h, 1.00kmol / h) and chlorine gas (142kg / h, 2.00kmol / h) through a metering pump. The reaction temperature is controlled at 50°C, and 2,4-dichloro Phenol content, control the content of 2,4-dichlorophenol to be greater than 90.0%, recover hydrogen chloride gas, and the synthesis yield is 96.9%.

example 2

[0023] Adopt 3-5 stage series continuous reactor, pass into 2,4-dichlorophenate sodium solution (185kg / h, 1.00kmol / h), sodium chloroacetate solution (118kg / h, 1.00kmol / h), reaction temperature At 80°C, the reaction liquid overflows from the last stage of the reaction kettle to the cooling kettle, and the temperature is lowered to 50°C. The cooled material enters the integrated suction filtration and washing machine to obtain the sodium salt of 2,4-dichlorophenoxyacetic acid.

example 3

[0025] Using 2-3 series continuous reactors, feed 2,4-dichlorophenoxyacetic acid sodium salt solution (243kg / h, 1.00kmol / h), 36.5% hydrochloric acid (100kg / h, 1.00mol / h), The pH value is adjusted, and the material enters the integrated suction filter and washing machine to obtain 2,4-dichlorophenoxyacetic acid with a content of 98.2% and a yield of 97.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com