Industrial synthesis method of high-thermal-stability terminated polyaryletherketone resin

A technology with high thermal stability and polyaryletherketone, which is applied in the field of polymer materials, can solve the problems of depolymerization and high equipment costs, and achieve the effects of reducing production costs, weak toxic and side effects, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

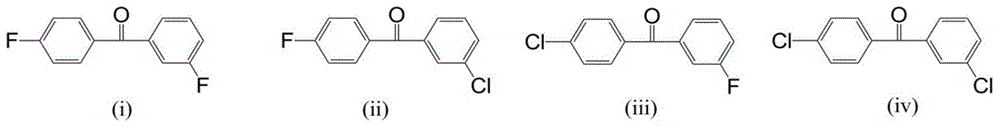

Image

Examples

Embodiment 1

[0039]In a 200-liter stainless steel reaction kettle equipped with a nitrogen pipe and a high-efficiency stirrer, first add 90.00KG diphenyl sulfone, 30.000KG 4,4'-difluorobenzophenone and 16.000KG sodium carbonate and start to heat up to 130-140 ℃, after the monomers are completely dissolved, add 14.000KG hydroquinone to the system, continue to stir evenly, then raise the temperature to 180℃~220℃, react for 1~2 hours, raise the temperature to 240℃~260℃, and react for 0.5~ After 2 hours, raise the temperature to 270°C-280°C, react for 0.5-2 hours, then raise the temperature to 310°C-320°C to polymerize for 1-4 hours, add 340.3g of 3,4'-difluorobenzophenone, and continue the reaction for 10- After 30 minutes, the polymerized mucus was obtained; the polymerized mucus was water-cooled and pulverized into powder or directly formed into a film on a stainless steel belt cooler and then pulverized, and then the filtered powder was added to ethanol and refluxed for 1 hour, so repeated ...

Embodiment 2

[0043] In a 200-liter stainless steel reaction kettle equipped with a nitrogen pipe and a high-efficiency stirrer, first add 90.00KG diphenyl sulfone, 30.000KG 4,4'-difluorobenzophenone, and 28.000KG 4,4'-dihydroxydiphenyl After ketone and 16.000KG sodium carbonate, the temperature starts to rise to 130-140°C, and after the monomers are completely dissolved, the temperature is raised to 180°C-220°C, and the reaction is 1-2 hours, and the temperature is raised to 240-260°C, and the reaction is 0.5-2 hours. Raise the temperature to 270°C-280°C, react for 0.5-2 hours, then raise the temperature to 310°C-320°C to polymerize for 1-4 hours, add 283.7g of 3,4'-difluorobenzophenone, and continue the reaction for 10-30 minutes. Polymerized mucus is obtained; the polymerized mucus is water-cooled and pulverized into powder or directly formed into a film on a stainless steel belt cooler and then pulverized, and then the filtered powder is added to ethanol and refluxed for 1 hour. Repeat t...

Embodiment 3

[0047] Same as Example 2, except increasing the amount of 3,4'-difluorobenzophenone to 340.3g, other conditions are the same.

[0048] The resulting PEK resin melt index MI = 25.4g / 10min (400.0 ° C, 5KG, 5 minutes);

[0049] MI=25.0g / 10min (400.0°C, 5KG, 30 minutes).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com