A method and system for dechlorination of waste plastics based on steam flow dispersion blowing

A technology of waste plastic and steam flow, applied in the field of waste plastic dechlorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

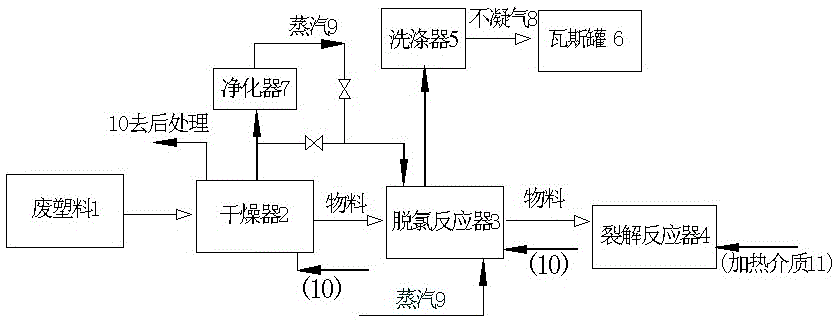

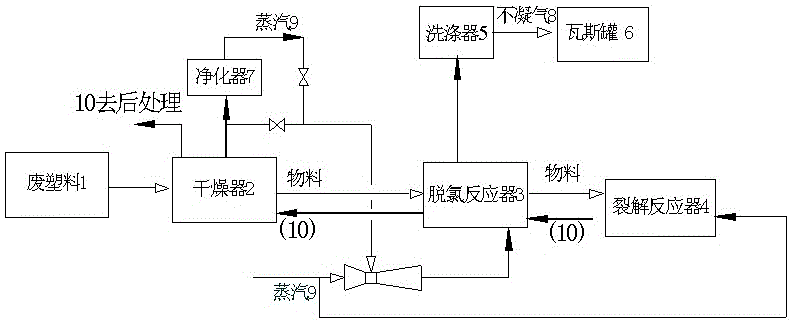

[0034] Example 1: Waste plastic 1 contains PE, PP, PS, PVC, etc.; comes from domestic waste; and is slightly polluted by food residues. The waste plastic needs to be pyrolyzed and gasified to produce combustible gas. Using the waste plastic dechlorination method based on steam flow dispersion and blow-off of the present invention, the preliminarily broken waste plastic 1 is sent to the dryer 2, and the dryer 2 adopts a rotary kiln type, and the steam generated is sent to the dechlorinator after passing through the purifier 7. Chlorine Reactor 3. Purifier 7 is a cyclone dust collector. At the same time, the steam 9 from the waste heat boiler of the system is 1.0MPa, and the waste steam generated in the drier 2 is injected by this high-pressure steam, and sent to the dechlorination reactor 3 together, see figure 2 . The waste plastic 1 is heated to 305° C. in the dechlorination reactor 3 . Dechlorination reactor 3 is a rotary kiln reactor with a feed rate of 1.25t / h; the to...

Embodiment 2

[0035] Example 2: Waste plastic 1 contains PE, PP, PVC, etc.; it is waste plastic sorted from papermaking waste. The waste plastic needs to be pyrolyzed to produce fuel oil, combustible gas and charcoal. Using the waste plastics dechlorination method based on steam flow dispersion and blow-off of the present invention, the waste plastics 1 are preliminarily crushed and then sent to the dryer 2. The dryer 2 adopts a rotary kiln dryer and is heated by flue gas discharged from the waste heat boiler of the system. The steam generated in the dryer 2 is sent to the dechlorination reactor 3, as figure 1 . Waste plastic 1 is heated to 318° C. in dechlorination reactor 3 . The dechlorination reactor 3 is a shaftless spiral reactor that can be reversed, and the feed rate is 1.1t / h; the superheated steam discharged from the boiler of the paper mill is 280°C, and is sent to the dechlorination reactor 3 after depressurization. The steam volume of the part is 495Nm 3 / h; It can efficien...

Embodiment 3

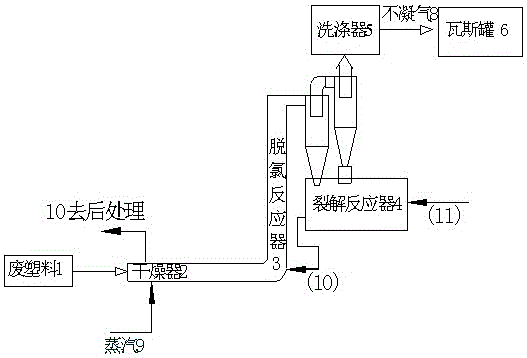

[0036] Example 3: Waste plastic 1 contains PE, PP, PVC, etc.; comes from medical waste; and is polluted by disinfectant water, antibiotics, and saline for injection. The waste plastic 1 needs to be pyrolyzed to produce fuel oil, combustible gas and charcoal. Using the waste plastic dechlorination method based on steam flow dispersion and blow-off of the present invention, the waste plastic 1 is directly sent to the dryer 2, and the dryer 2 adopts a vacuum paddle dryer, and the external jacket is produced by a waste heat boiler of the system 0.6MPa steam heating. The steam generated in the dryer 2 is directly injected into the dechlorination reactor 3 by the steam 9 with a pressure of 0.6 MPa. The waste plastic 1 is heated to 330° C. in the dechlorination reactor 3 . Dechlorination reactor 3 is a paddle-stirred reactor with a feed rate of 1.0t / h; the total amount of steam is 467Nm 3 / h; can efficiently separate organic Cl and inorganic Cl in waste plastics, and the separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com