A method for inhibiting migration of plasticizer in esterified starch film and esterified starch film

A technology of esterified starch and plasticizer, which is applied in the field of inhibition of plasticizer in esterified starch-based biodegradable packaging materials, can solve the problems of neglecting the regulation of interaction of polymer materials, and achieves good use effect and operation. Strong and wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for suppressing plasticizer migration in esterified starch films, carried out through the following steps:

[0022] (1) Add starch milk with a water content of 40% into a high-temperature and high-pressure reactor, control the pH of the system to 9, then add 2ml / g of acetic anhydride (calculated on a dry basis of starch) and stir for 0.5h at a temperature of 80°C. After the reaction is completed, add water to precipitate, filter, and dry to obtain acetate-esterified starch with a substitution degree of 1.17.

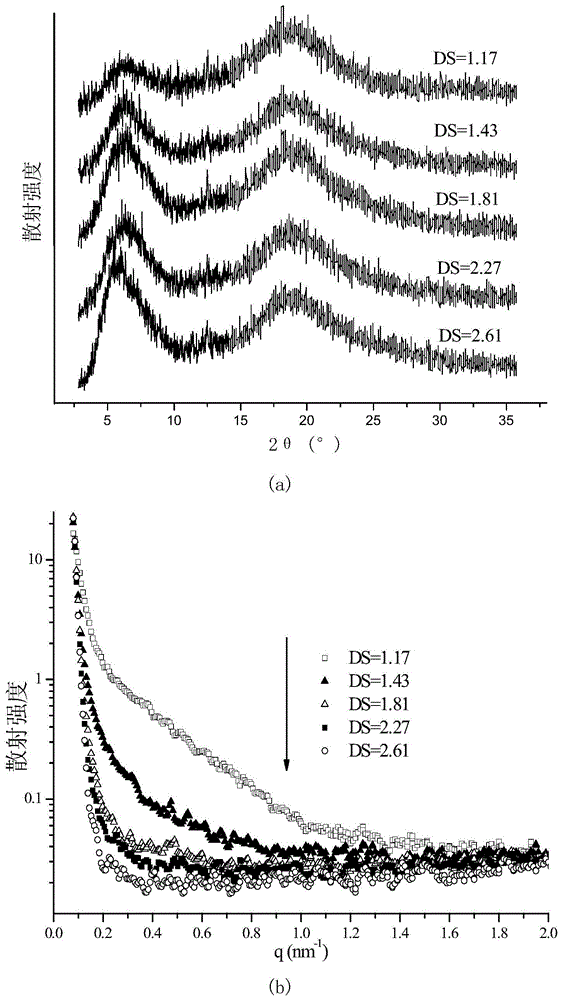

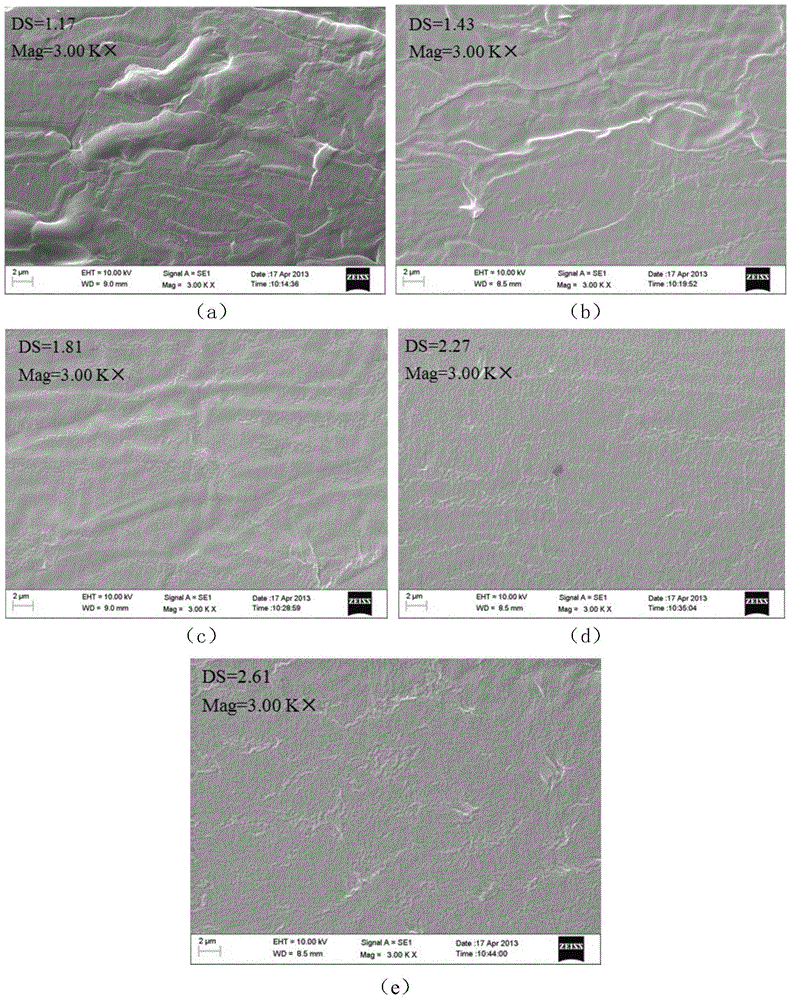

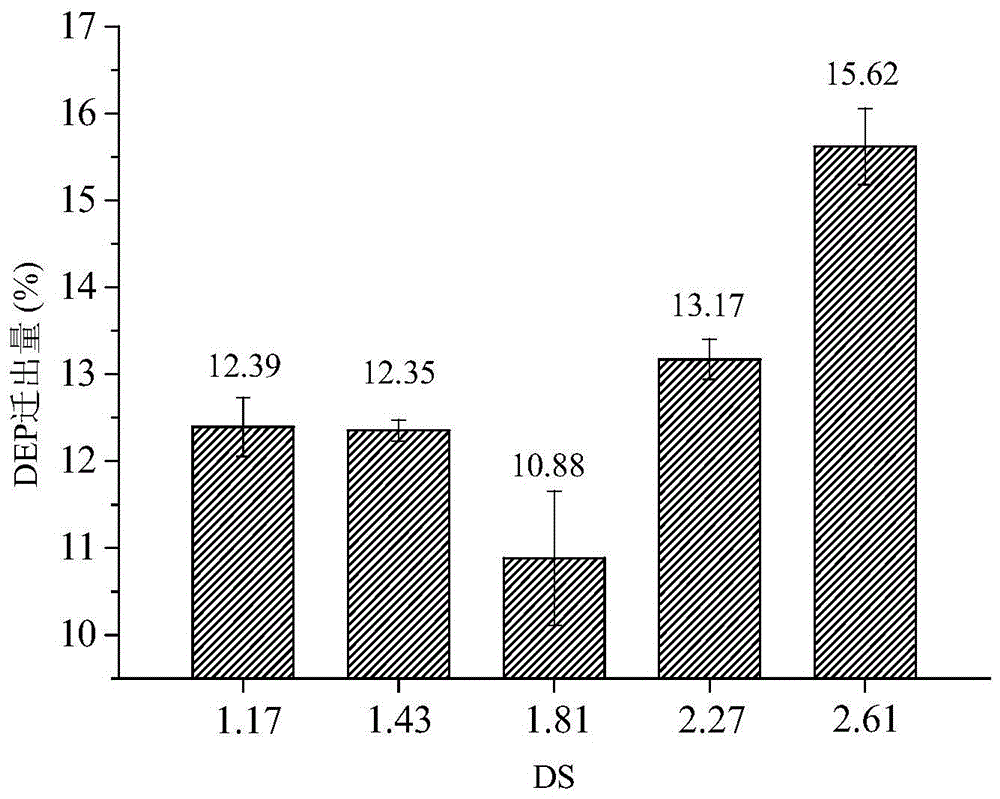

[0023] (2) dissolving the acetate-esterified starch obtained in step (1) in acetone to form a solution with a mass percentage concentration of 4%, adding plasticizer diethyl phthalate 20% (w / w, in the form of ester Starch dry basis) using a fluidized bed at 50 ° C, with a spray rate of 1.0mL / min and an atomization pressure of 1.0 MPa, it is sprayed into a translucent film on a polytetrafluoroethylene plate to obtain an esterified starch film (such as figu...

Embodiment 2

[0025] A method for suppressing plasticizer migration in esterified starch films, carried out through the following steps:

[0026] (1) Add starch milk with a water content of 70% into a high-temperature and high-pressure reactor, control the pH of the system to 10.5, then add 3ml / g of propionic anhydride (based on starch dry basis) and stir for 0.5h at a temperature of 90°C. After the reaction is completed, add water to precipitate, filter, and dry to obtain acetate-esterified starch with a substitution degree of 1.43.

[0027] (2) dissolving the acetate-esterified starch obtained in step (1) in acetone to form a solution with a mass percentage concentration of 4%, adding plasticizer diethyl phthalate 20% (w / w, in the form of ester Starch dry basis) Utilize fluidized bed at 52 ℃, with spraying rate 2.0mL / min, atomization pressure is 0.5MPa to spray on polytetrafluoroethylene board into translucent film, promptly obtains esterified starch film (such as figure 2 shown).

Embodiment 3

[0029] A method for suppressing plasticizer migration in esterified starch films, carried out through the following steps:

[0030] (1) Add starch milk with a water content of 60% into a high-temperature and high-pressure reaction kettle, control the pH of the system to 10.5, then add 3ml / g of propionic anhydride (based on starch dry basis) and stir at a temperature of 90°C for 1.5h, After the reaction is completed, add water to precipitate, filter, and dry to obtain acetate-esterified starch with a substitution degree of 1.81.

[0031] (2) dissolving the acetate-esterified starch obtained in step (1) in acetone to form a solution with a mass percentage concentration of 4%, adding plasticizer diethyl phthalate 20% (w / w, in the form of ester Starch dry basis) Utilize fluidized bed at 50 ℃, with spray rate 1.0mL / min, atomization pressure is 1.2MPa to spray on polytetrafluoroethylene board into translucent film, promptly obtains esterified starch film (such as figure 2 shown). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com