Cobalt leaching method of cobalt-leached composite acid based on synthetic polycrystalline diamond composite sheet

A technology of polycrystalline diamond and composite acid, which is applied in the field of materials for oil exploration drill bits, can solve problems such as increased internal stress, increased volume, and different thermal expansion coefficients, and achieves the effects of increased resistivity and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

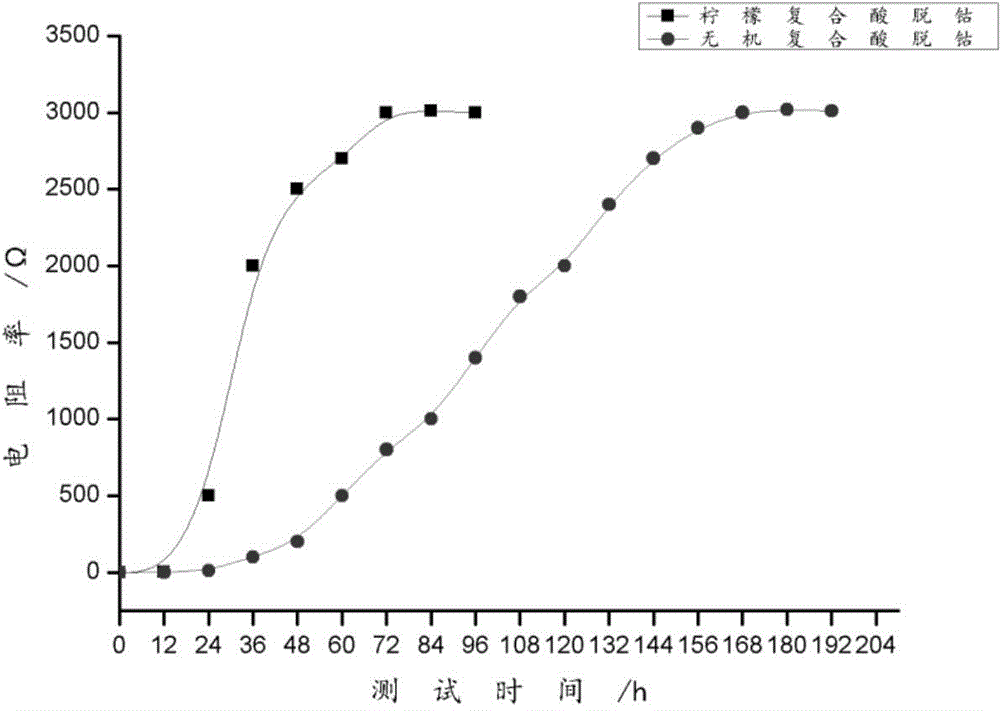

[0027] The present invention utilizes compound acid to the efficient decobalt method of artificial polycrystalline diamond composite sheet, comprises the following steps:

[0028] 1) Configure 100ml of oxalic acid solution with a mass concentration of 40g / L;

[0029] 2) 100ml of hydrochloric acid solution with a mass concentration of 15g / L is mixed with the solution obtained in step 1);

[0030] 3) 100ml of hydrofluoric acid solution with a mass concentration of 20g / L is mixed with the solution obtained in step 2) to obtain a composite acid solution;

[0031] 4) Immersing the synthetic polycrystalline diamond composite sheet in the prepared composite acid solution;

[0032] Element

[0033] 5) After preparing the composite acid solution according to the above method, immerse the synthetic polycrystalline diamond composite sheet in the prepared composite acid solution, and keep the temperature at 70° C. for 72 hours.

Embodiment 2

[0035] The present invention utilizes compound acid to the efficient decobalt method of artificial polycrystalline diamond composite sheet, comprises the following steps:

[0036] 1) 100ml of oxalic acid solution with a mass concentration of 50g / L;

[0037] 2) 100ml of sulfuric acid solution with a mass concentration of 18g / L is mixed with the solution obtained in step 1);

[0038] 3) 100ml of boric acid solution with a mass concentration of 22g / L is mixed with the solution obtained in step 2) to obtain a compound acid solution;

[0039] 4) Immersing the synthetic polycrystalline diamond composite sheet in the prepared composite acid solution;

[0040] Element

[0041] 5) Immerse the synthetic polycrystalline diamond composite sheet in the compound acid solution prepared in the above table, and keep the temperature at 80°C for 48 hours.

Embodiment 3

[0043] The present invention utilizes compound acid to the efficient decobalt method of artificial polycrystalline diamond composite sheet, comprises the following steps:

[0044] 1) preparation mass concentration is 100ml of citric acid solution of 50g / L;

[0045] 2) 100ml of hydrochloric acid solution with a mass concentration of 1g / L is mixed with the solution obtained in step 1);

[0046] 3) 100ml of hydrofluoric acid solution with a mass concentration of 15g / L is mixed with the solution obtained in step 2) to obtain a composite acid solution;

[0047] 4) Immersing the synthetic polycrystalline diamond composite sheet in the prepared composite acid solution;

[0048] Element

[0049] 5) After preparing the composite acid solution according to the above method, immerse the artificial polycrystalline diamond composite sheet in the prepared composite acid solution, and keep the temperature at 75° C. for 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com