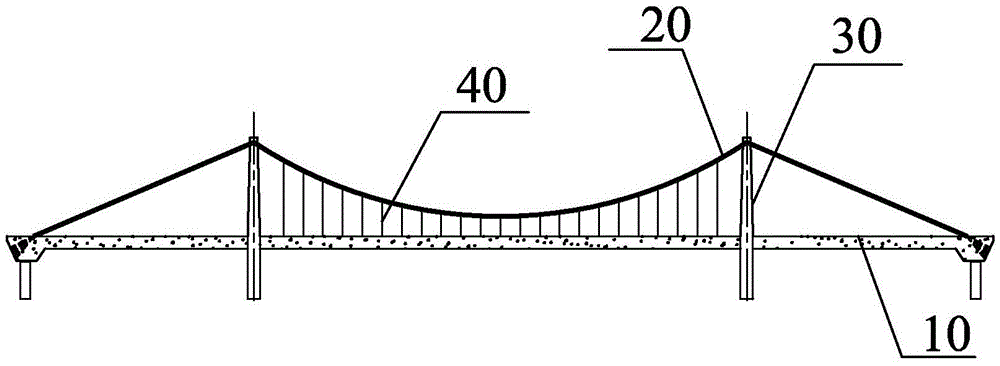

Self-anchored suspension bridge with fish spine structure

A self-anchored suspension bridge and fish-back beam technology, applied in suspension bridges, bridge forms, bridges, etc., can solve the problems of complex local stress in the anchoring area, large volume of main cables and suspender anchoring beams, and limited spans, etc., and achieve multi-modeling. Design imagination space, diversify landscape design, reduce the effect of height control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

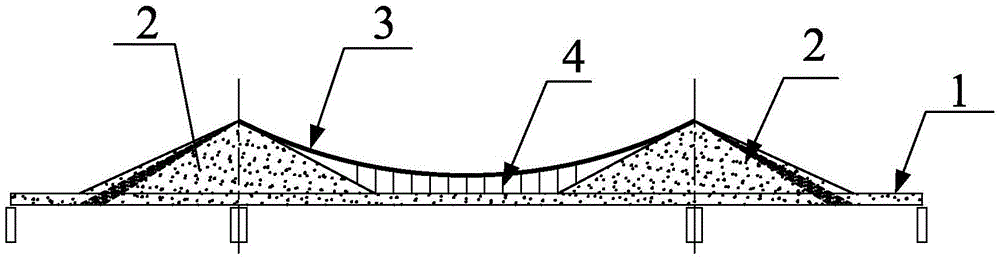

Embodiment 1

[0063] The purpose of the present invention is achieved through the following technical solutions: as figure 2 As shown, the self-anchored suspension bridge of the fish spine structure provided by the present embodiment is a self-anchored suspension bridge with a double span three-span fish spine structure, which includes: a main beam of a fish spine structure, several main cables 3, and the main cables 3 The girder comprises: a full-length box-type deck 1 of equal height, and several variable-height fish ridge walls 2 erected on the same-height box-type deck, and several tensioned ridges arranged between the main cables 3 and The suspenders 4 between the equal-height box-type bridge decks 1, the equal-height box-type bridge deck 1 and the fish ridge wall 2 are formed by concrete pouring, and the two ends of each main cable 3 are anchored on two adjacent fish bridges. Inside the fish ridge of ridge wall 2. By means of several variable-height fish-ridge walls erected on the s...

Embodiment 2

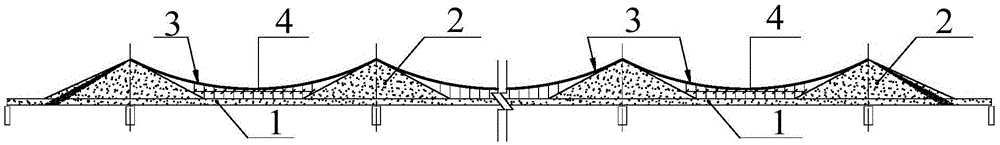

[0080] On the facade, the span diameter, number of spans, number of main cables, and number of suspenders are not limited according to actual engineering and force requirements. Therefore, the present embodiment provides a self-anchored suspension bridge with multi-tower and multi-span fish-back structure.

[0081] image 3 The elevation direction structure diagram of the self-anchored suspension bridge with multi-tower span fish-back structure.

[0082] Such as image 3 As shown, the number of main cables 3 of the self-anchored suspension bridge in this embodiment is multiple, and the number of spans of the self-anchored suspension bridge is multiple.

[0083] The structures of the fish ridge wall 2 , the main cable 3 , and the contoured box bridge deck 1 in this embodiment, as well as the connection methods between the suspender 4 and the main cable 3 , and the fish ridge wall 2 are all identical to those in Embodiment 1.

Embodiment 3

[0085] According to the needs of actual engineering and stress, the fish ridge wall of the self-anchored suspension bridge in this embodiment is a single fish ridge wall.

[0086] Figure 4a It is the layout structure diagram of the monolithic fish ridge wall and bridge tower in the direction of cross section. Such as Figure 4a As shown, the single-piece fishback wall is arranged in the middle of the cross-section of the equal-height box-type bridge deck 1 .

[0087] The structures of the fish ridge wall 2 , the main cable 3 , and the contoured box bridge deck 1 in this embodiment, as well as the connection methods between the suspender 4 and the main cable 3 , and the fish ridge wall 2 are all identical to those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com