Engine intake and exhaust system and vehicle

An engine, intake and exhaust technology, used in engine components, combustion engines, machines/engines, etc., can solve problems such as harmful gases and particulate matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

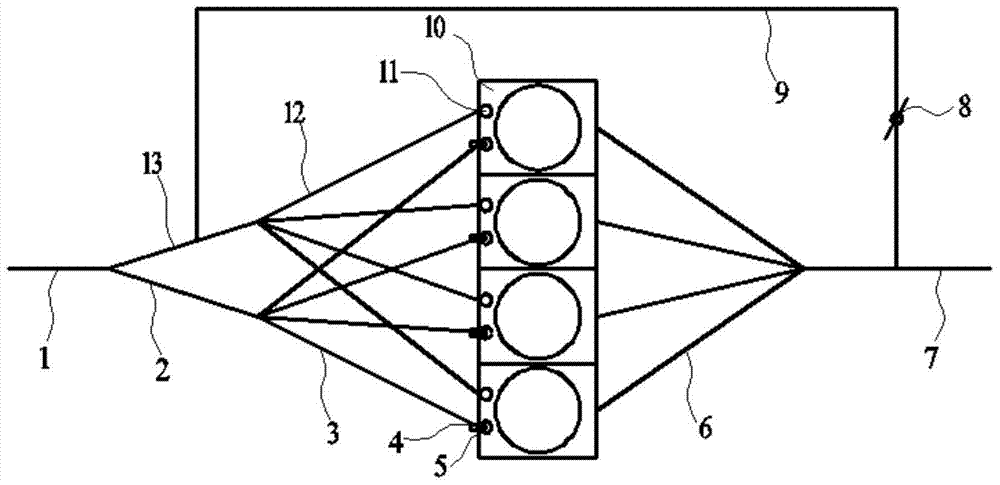

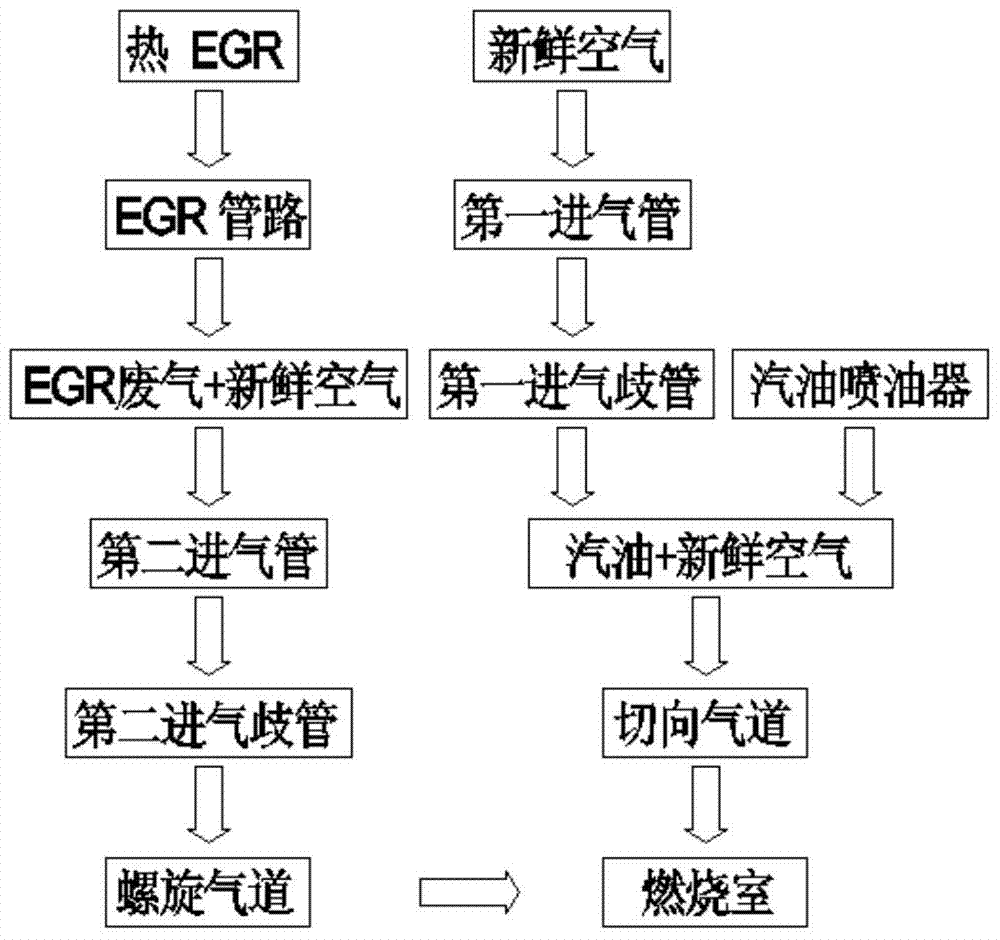

[0030] Taking a four-cylinder dual-fuel engine as an example, such as figure 1 shown. This type of fuel engine is an engine that injects gasoline premixed into the port and injects diesel fuel into the cylinder to ignite.

[0031] An embodiment of the present invention is an engine intake and exhaust system, such as figure 1 Shown, comprise cylinder (four), and cylinder is provided with tangential air passage 5 and spiral air passage 11; Tangential air passage 5 connects first intake manifold 3, and first intake manifold 3 (four) common Connect the first intake pipe 2; the spiral air channel 11 connects the second intake manifold 12, and the second intake manifold 12 (four) connects the second intake pipe 13; the second intake pipe 13 is connected with the exhaust manifold of the engine 7 is connected with an EGR pipeline 9 of the exhaust gas recirculation system, and an EGR valve 8 is arranged on the EGR pipeline 9 .

[0032] Such as figure 1 and figure 2 As shown, the ...

Embodiment 2

[0044] The embodiment of the present invention is a vehicle provided with the engine intake and exhaust system in the first embodiment above.

[0045] Compared with the prior art, the vehicle in this embodiment has the same advantages as the engine intake and exhaust system in the first embodiment above, that is, it can effectively reduce the emission of harmful gases such as HC, CO and NOx, and particulate matter , and its specific working principle will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com