A preparation method of a multi-band absorbing near-infrared sunlight dye-sensitized solar cell photoanode material

A technology for solar cells and dye sensitization, applied in the field of preparation of photoanode materials for dye-sensitized solar cells, can solve the problem of low utilization of sunlight in the infrared band, and achieve the effects of avoiding quenching effects, large specific surface area, and increasing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

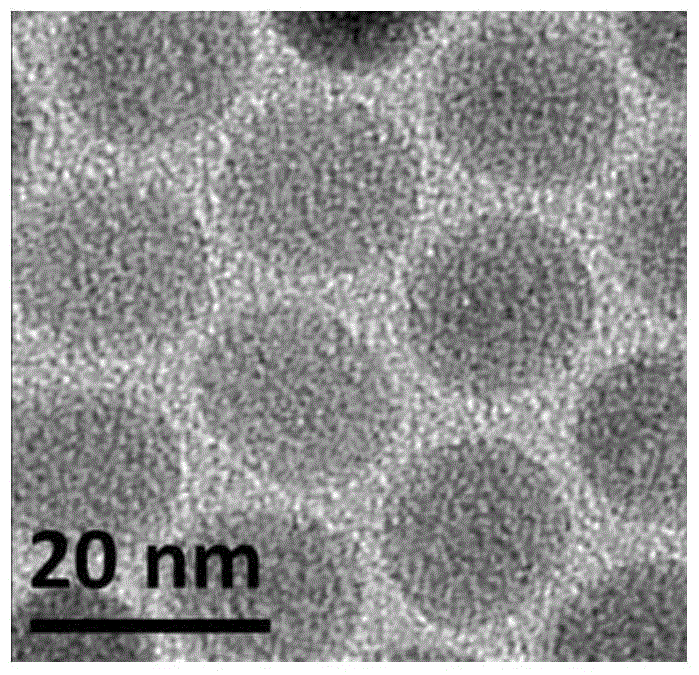

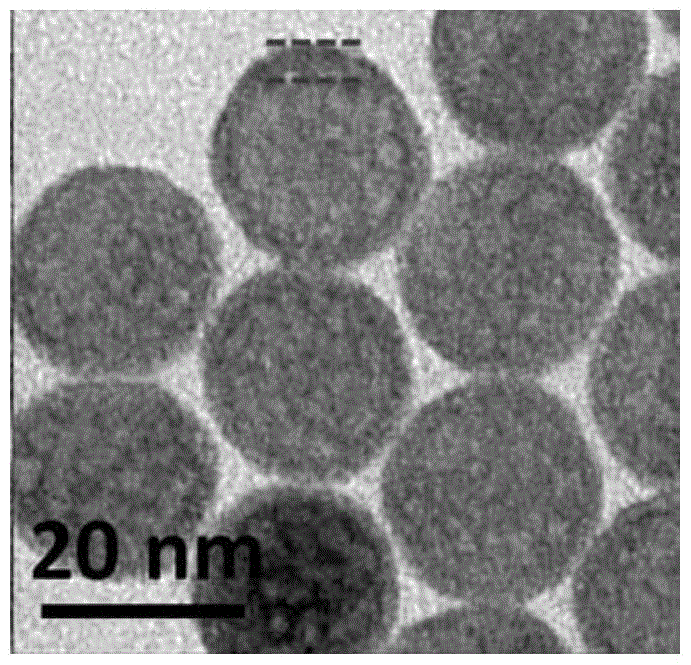

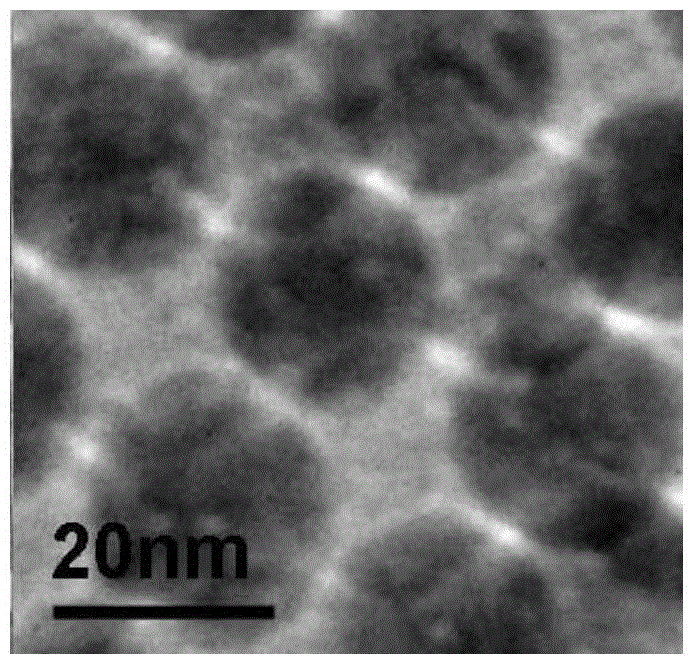

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: The preparation method of the multi-band absorption near-infrared sunlight dye-sensitized solar cell photoanode material of this embodiment is carried out according to the following steps:

[0030] Step 1: According to the volume ratio of oleic acid and octadecene is 1:2~5, mix oleic acid and octadecene evenly to obtain a mixed solution, and then press yttrium chloride (YCl 3 ), ytterbium chloride (YbCl 3 ) and Erbium Chloride (ErCl 3 ) in a molar ratio of (80+m+n): (10-m): (10-n), yttrium chloride, ytterbium chloride and erbium chloride are added to the mixture, stirred evenly, heated to 120 ~150°C and keep it for 30~60min, then naturally cool to room temperature to obtain raw material solution A; where 0≤m<10, 0≤n<10;

[0031] Step 2: Weigh ammonium fluoride (NH 4 F) and sodium hydroxide (NaOH) are dissolved in methanol, obtain raw material liquid B; Wherein NH 4 The molar ratio of F to NaOH is 1: (0.5-2);

[0032] Step 3: Under the protection of ni...

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the ratio of the molar sum of yttrium chloride, ytterbium chloride and erbium chloride to the volume of the mixed solution in step one is 1mmol: 9~30ml; other It is the same as the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stirring speed in Step 1 is 800-1000 r / min; the others are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com