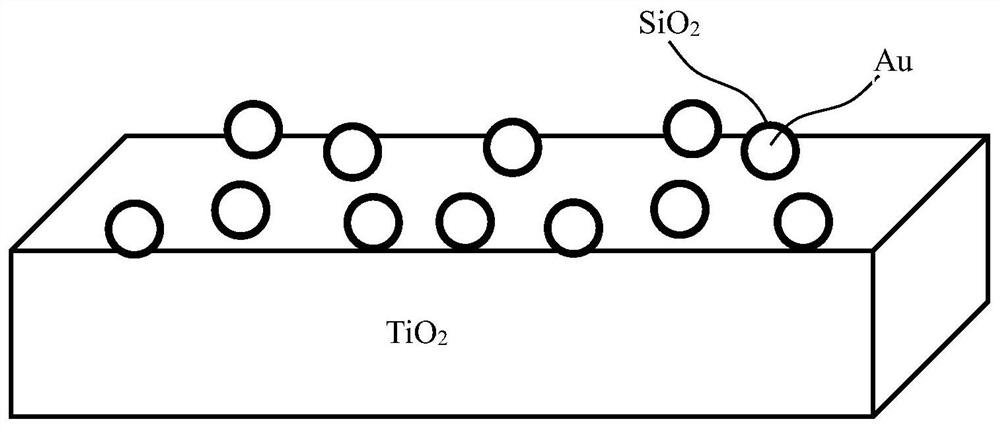

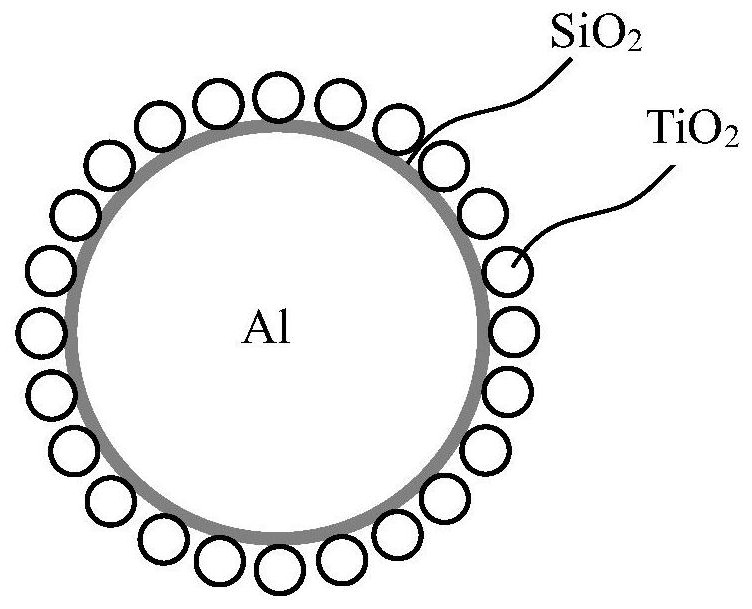

Aluminum-silicon dioxide-titanium dioxide composite photocatalyst and preparation method thereof

A technology of silicon dioxide and titanium dioxide, applied in the field of photocatalysis, can solve the problems of enhancing the photocatalytic effect of semiconductors, weak plasmon resonance effect, and high price of precious metals, avoiding electron quenching effect, enhancing photocatalytic efficiency, and increasing production rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Add 10 mg of Al nanoparticles into 30 mL of ethanol and water mixed solution, the volume ratio of ethanol and water is 5:1, and use an ultrasonic cell pulverizer to ultrasonically disperse for 20 minutes to obtain a suspension of Al nanoparticles.

[0025] 2. Add 44.9 mg of cysteine to the Al nanoparticle suspension, stir at a speed of 500 r / min for 20 min at a temperature of 30 ° C, then add 10 mg of polyvinylpyrrolidone (PVP), and continue to Stir at the stated temperature for 15min at the stated rotating speed to obtain a surface-modified Al nanoparticle suspension;

[0026] 3. Dissolve 0.2 mL of tetraethyl orthosilicate (TEOS) in 5 mL of absolute ethanol to obtain tetraethyl orthosilicate ethanol solution; first add 1 mL of NH to the surface-modified Al nanoparticle suspension 3 ·H 2 O solution; then add the ethanol solution of tetraethyl orthosilicate dropwise at a rate of 20 s / mL to the surface-modified Al nanoparticle suspension; Stir for 6 hours at a cons...

Embodiment 2

[0030] 1. Add 30 mg of Al nanoparticles into 30 mL of ethanol and water mixed solution, the volume ratio of ethanol and water is 4:1, and use an ultrasonic cell pulverizer to ultrasonically disperse for 40 minutes to obtain a suspension of Al nanoparticles.

[0031] 2. Add 134.7 mg of cysteine to the Al nanoparticle suspension, stir at a speed of 1500 r / min for 15 min at a temperature of 40 ° C, then add 50 mg of polyvinylpyrrolidone (PVP), and continue to Stir at the stated temperature for 20min at the stated rotating speed to obtain a surface-modified Al nanoparticle suspension;

[0032] 3. Dissolve 1 mL of tetraethyl orthosilicate (TEOS) in 5 mL of absolute ethanol to obtain tetraethyl orthosilicate ethanol solution; first add 1 mL of NH to the surface-modified Al nanoparticle suspension 3 ·H 2 O solution; then add the ethanol solution of tetraethyl orthosilicate dropwise at a rate of 60 s / mL to the surface-modified Al nanoparticle suspension; Stir for 10 hours at a con...

Embodiment 3

[0036] 1. Add 10 mg of Al nanoparticles into 30 mL of ethanol and water mixed solution, the volume ratio of ethanol and water is 5:1, and use an ultrasonic cell pulverizer to ultrasonically disperse for 40 minutes to obtain a suspension of Al nanoparticles.

[0037] 2. Add 134.7 mg of cysteine to the Al nanoparticle suspension, stir at a speed of 500 r / min for 20 min at a temperature of 40 ° C, then add 20 mg of polyvinylpyrrolidone (PVP), and continue to Stir at the stated temperature for 20min at the stated rotating speed to obtain a surface-modified Al nanoparticle suspension;

[0038] 3. Dissolve 0.5 mL of tetraethyl orthosilicate (TEOS) in 5 mL of absolute ethanol to obtain tetraethyl orthosilicate ethanol solution; first add 1 mL of NH to the surface-modified Al nanoparticle suspension 3 ·H 2 O solution; then add the ethanol solution of tetraethyl orthosilicate dropwise at a rate of 50 s / mL to the surface-modified Al nanoparticle suspension; Stir for 10 hours at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com