Non-contact liquid level detection device and non-contact liquid level detection method

A liquid level detection, non-contact technology, applied in the liquid level indicator of physical variable measurement, etc., can solve the problems of dead angle, float stuck, easy to clean and dirty, etc., to prolong service life, simplify structure, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0054] The present invention also provides a second embodiment of a non-contact liquid level detection method, which includes:

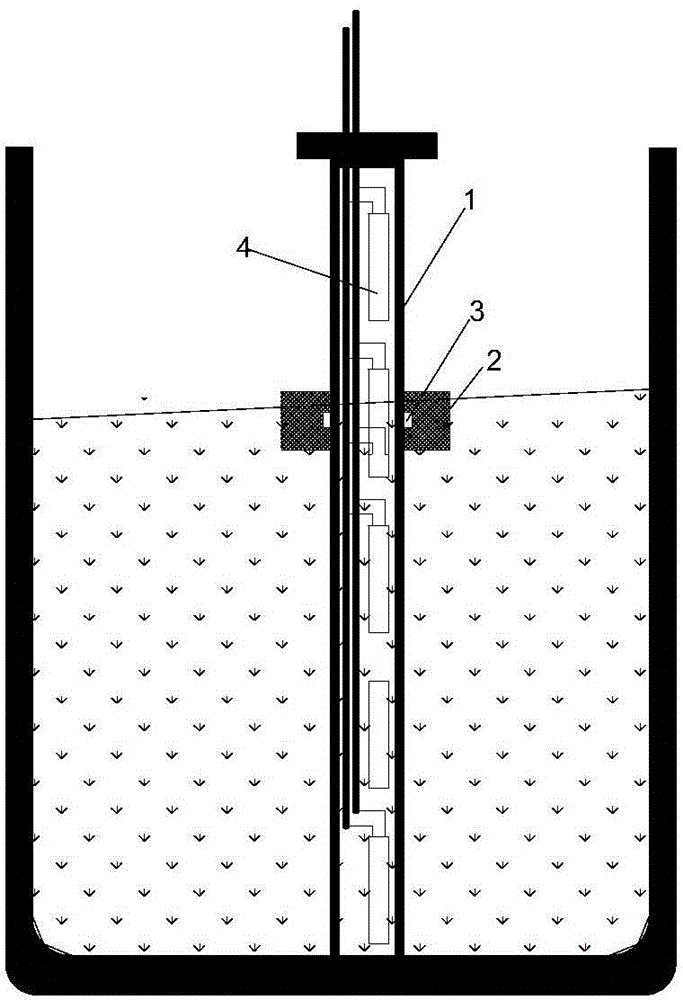

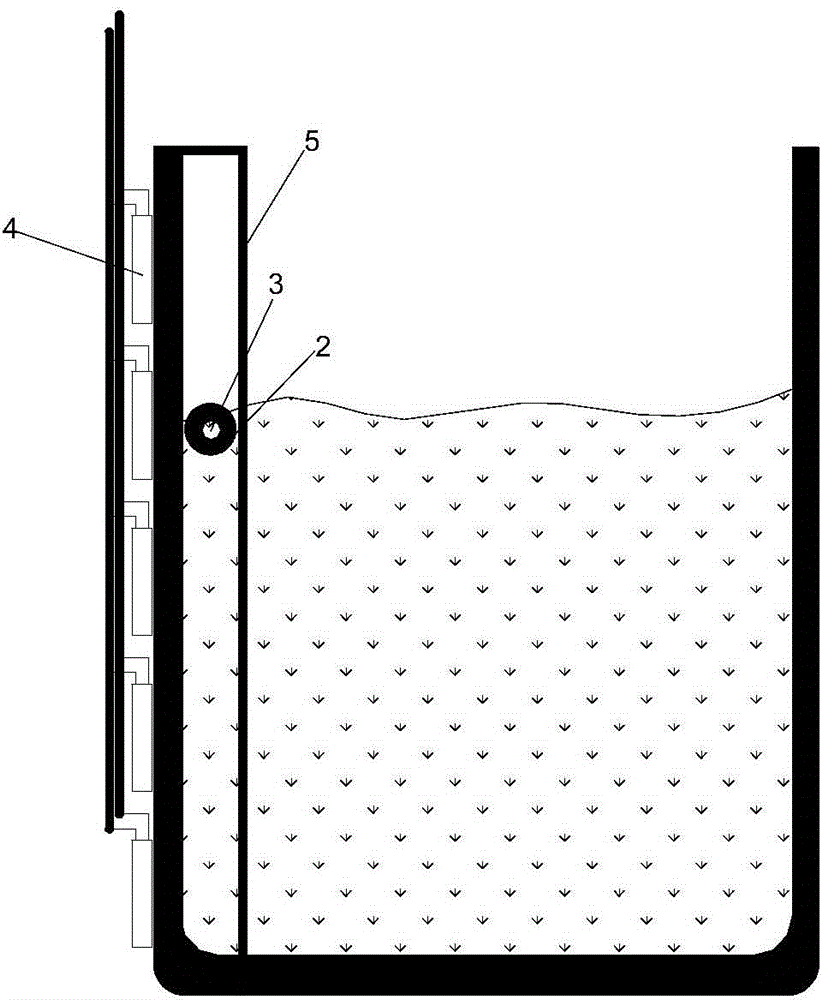

[0055] First provide a detection board 20 located outside the container, at least one sensing unit 21 disposed on the detection board 20, a control unit 22 disposed on the detection board 20 and connected to the output of the at least one sensing unit 21, and the control unit The upper computer 24 connected to the output of 22, wherein the sensing unit 21 is copper clad;

[0056] Then detect the corresponding capacitance value of each sensing unit 21 when the container has no liquid, and store the capacitance value data at this time into the control unit 22 as a reference reference capacitance value; Figure 8 As shown, it is a schematic diagram of the self-capacitance equivalent capacitance distribution. There is an inherent parasitic capacitance Cp (also known as self-capacitance) in one or more sensing units 21 relative to the negative pole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com