Testing device and method for carbon fiber strand integrity

A test device and test method technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of not being able to meet customer needs, not being able to find cluster quantitative evaluation, etc., and achieve simple and clear test methods, low production costs, The effect of safe and fast operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

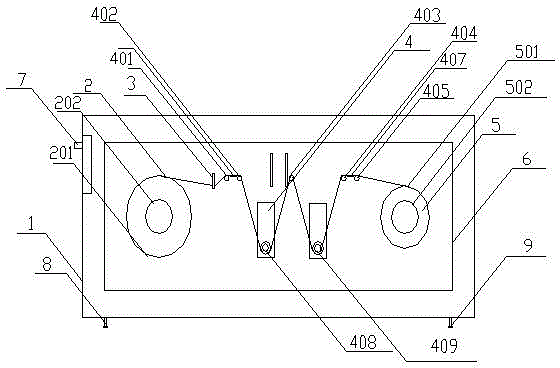

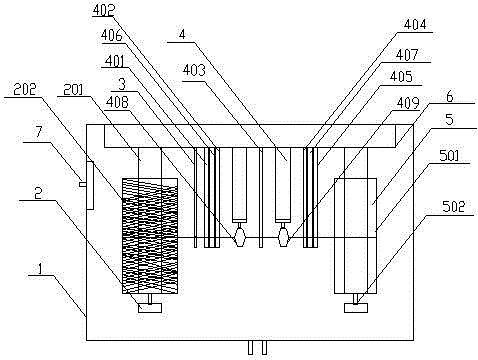

Embodiment 1

[0042] Adjust the temperature of the test room to 20°C and the relative humidity to 40%, and use the left adjustment knob 8 and the right adjustment knob 9 to adjust the level of the test chamber body 1, open the front of the test chamber body 1, and stand in this environment for 2 Hours or more; select 5 spindles from the HF10-12K-A2 carbon fiber that need to test the clustering carbon fiber, the fixed length of the fiber is about 1100 meters, and place it in the above environment for 2 hours; the fiber spindle 202 is installed on the unwinding shaft 201 and Ensure that the fiber can be pulled out from its upper end, and the winding spindle 502 is fixed on the winding shaft 501; one of the selected fiber spindles is fixed on the unwinding device 2, and passes through the porcelain eye 3 and the transmission roller in sequence Mechanism 4, etc., wind up on the wire-receiving spindle 502 at last, and close the front of the test chamber 1; use the variable speed knob 7 to adjust ...

Embodiment 2

[0044] Adjust the temperature of the test room to 25°C and the relative humidity to 50%. Select 4 ingots from the HF30-12K-A2 carbon fiber. The fixed length of the carbon fiber that needs to be tested for clustering is about 2700 meters. Hours and through the detection of the test device in the test chamber 1, the speed change knob 7 adjusts the rotating speed of the wire receiving spindle 502 to be 15r / min, and the first to fourth test results are 46.3%, 47.9%, 49.6%, 48.1% respectively , taking the average value, the bundled carbon fiber of this model batch is 47.98%, and the dispersion coefficient is 2.61%.

Embodiment 3

[0046] Adjust the temperature of the test room to 27°C and the relative humidity to 60%. Select 3 ingots from the T700SC-12K-50C carbon fiber. The fixed length of the carbon fiber that needs to be tested for clustering is about 2500 meters. According to Example 1, place 2 in the above environment. Hours and through the test device detection in the test chamber 1, the speed change knob 7 adjusts the rotating speed of the wire receiving spindle 502 to be 20r / min, and the first to third test results are 33.3%, 32.5%, 30.08% respectively, taking the average It is estimated that the bundled carbon fiber of this model batch is 31.96., and the dispersion coefficient is 2.97%.

[0047] Compared with the prior art, the beneficial effect of this embodiment is: the test device designed by the present invention has a simple structure, no complicated parts, and low manufacturing cost. It can be operated after training, and the operation process is safe and fast. The present invention can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Coefficient of variation | aaaaa | aaaaa |

| Coefficient of variation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com