Micro data line physical foaming production device

A technology of physical foaming and production equipment, applied in electrical components, circuits, insulation of conductors/cables, etc., can solve the problem of physical foaming production equipment without fine high-frequency data lines, and achieve stable foaming degree and meet strict requirements. Performance requirements, the effect of high foaming degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

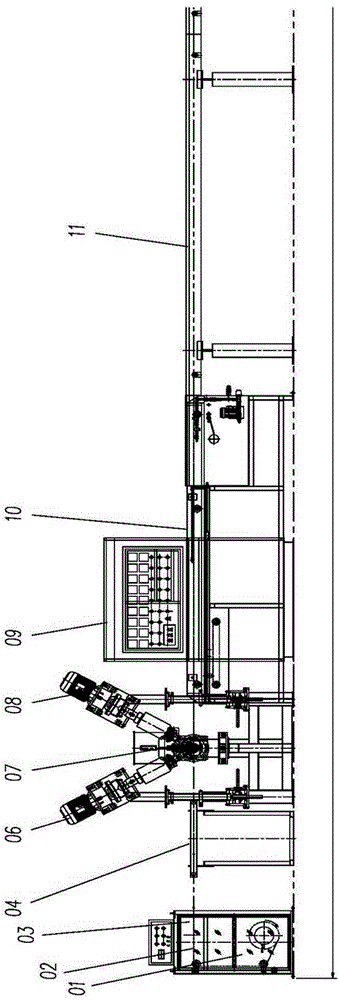

[0025] 1. Specifications and technical requirements of production cables:

[0026] Wire structure: inner skin layer - foam layer - outer skin layer;

[0027] Conductor diameter: φ0.32mm (28AWG);

[0028] Inner cortex thickness: 0.02mm, material: LDPE;

[0029] Foam layer thickness: 0.24mm, material: LDPE (70%) + HDPE (20%) + nucleating agent (10%);

[0030] Skin layer thickness: 0.05mm, material: HDPE;

[0031] Finished outer diameter: φ0.94±0.013;

[0032] Online capacitance value: 91.8±1.64 pf / m;

[0033] Withstanding voltage test: AC 1.8kv;

[0034] Concentricity: >85%.

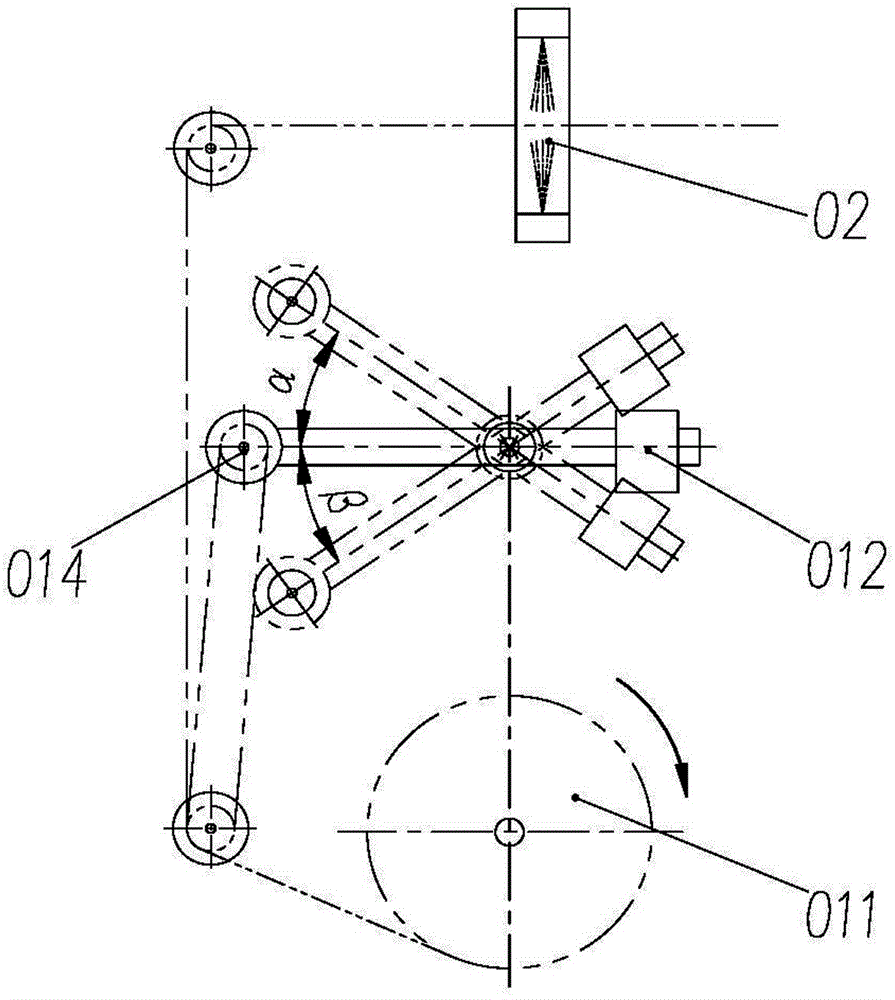

[0035] It can be seen from the above performance parameters of the wire rod that the diameter of the wire rod is small and the required tension value is very small. The weight of the guide wheels must be reduced as much as possible to reduce the resistance to the wire rod. Improve the control accuracy in the process, and the manufacturing accuracy of the equipment to meet the stringent performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com