OLED display substrate and manufacturing method of OLED display substrate

一种显示基板、制造方法的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决短路、不能形成、OLED无法发光等问题,达到改善接触阻抗、防止短路、保证正常发光的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

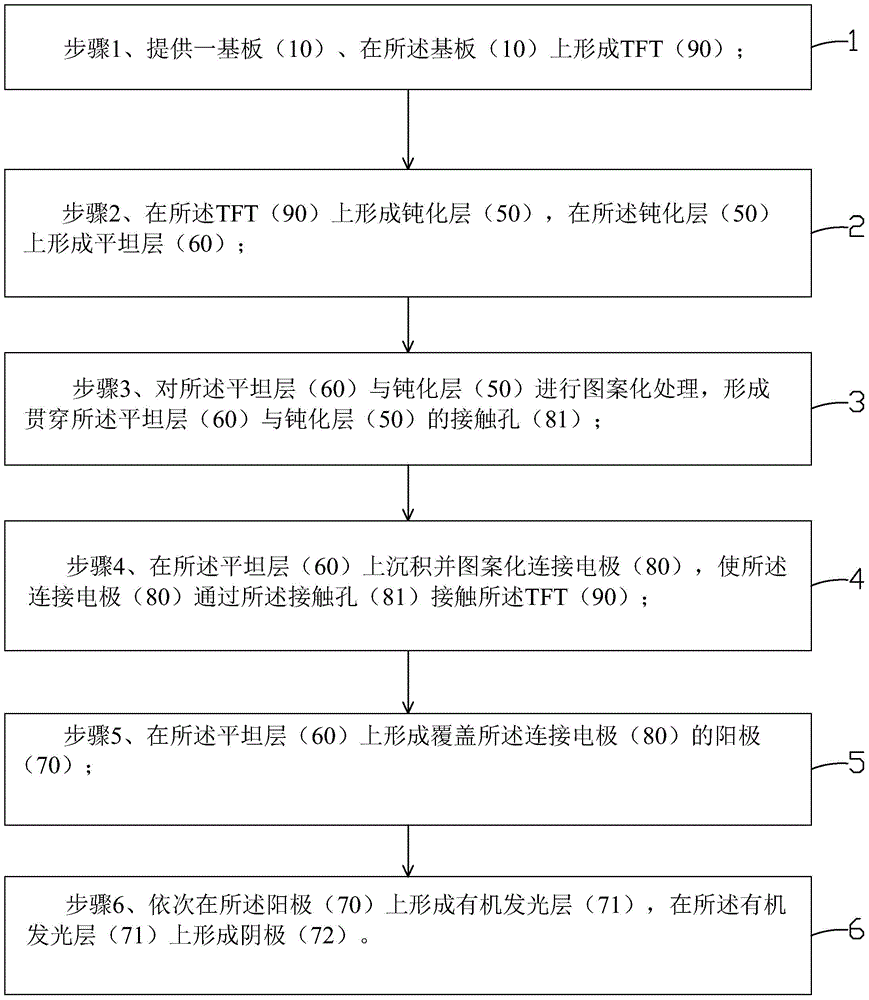

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

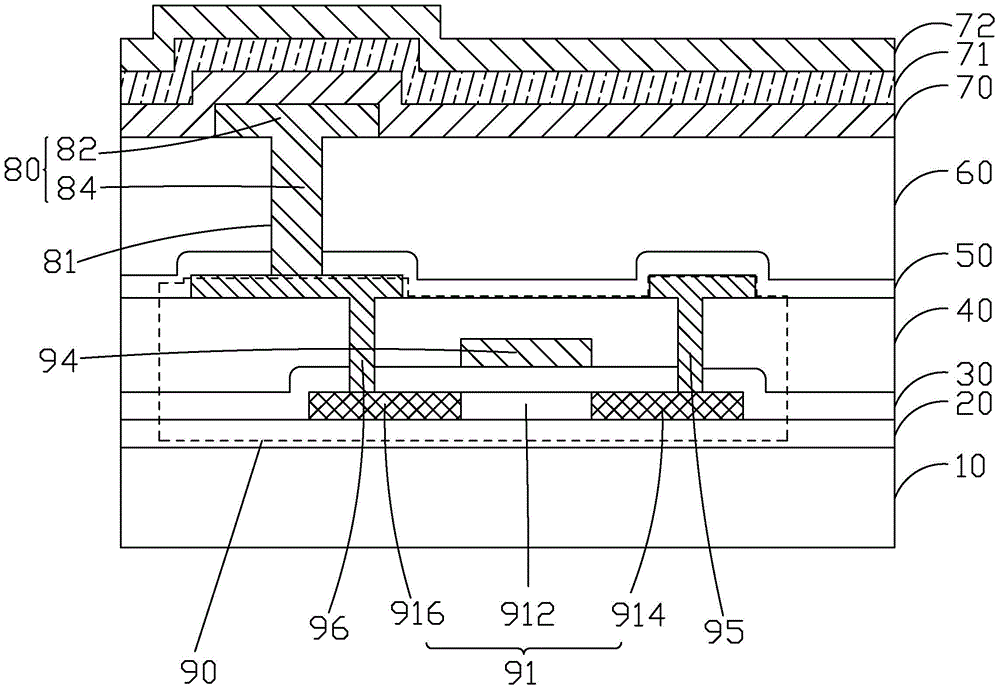

[0037] see figure 2 , the present invention firstly provides an OLED display substrate, comprising:

[0038] A substrate 10, the substrate 10 is a transparent substrate, preferably, the substrate 10 is a glass substrate;

[0039] The TFT 90 disposed on the substrate 10; specifically, the TFT 90 includes: a buffer layer 20 disposed on the substrate 10, a channel region 912 disposed on the buffer layer 20, respectively disposed on the The semiconductor layer 91 of the source region 914 and the drain region 916 on both sides of the channel region 912, the gate insulating layer 30 disposed on the semiconductor layer 91, and the gate insulating layer 30 disposed above the channel region 912 The gate 94 on the insulating layer 30 , the interlayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com