Wheat anti-dry hot wind preparation

A hot air and preparation technology, applied in biocides, animal repellents, plant growth regulators, etc., can solve the problems of extensive promotion restrictions, low yield increase benefits, low cost, etc., to improve cell viability, increase wheat thousand-grain weight and yield , Promote the effect of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

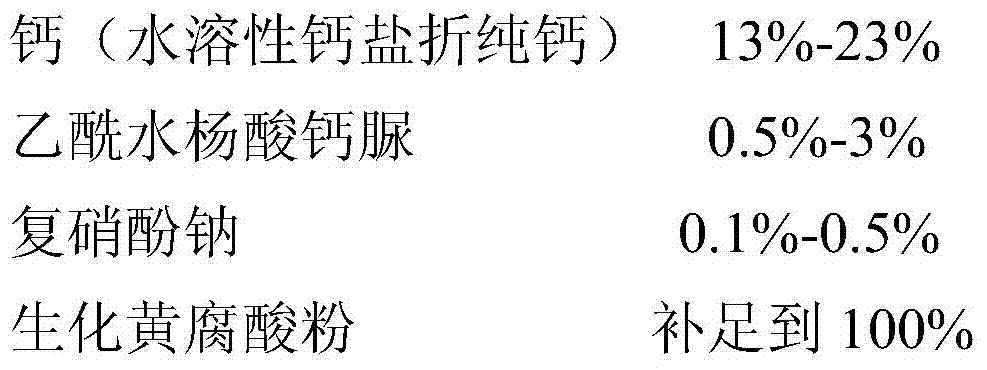

[0030] Powdered anhydrous calcium chloride 50% (18% for pure calcium), calcium urea acetylsalicylate 1.661%, sodium nitrophenolate 0.25%, biochemical fulvic acid powder 48.1%, mix according to the above ratio, fully stir and mix , bagged and named Kn-2 preparation.

Embodiment 2

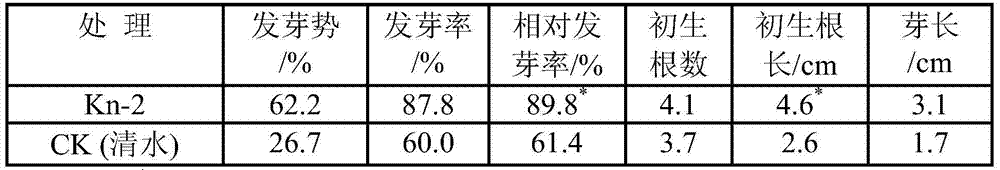

[0031] Example 2 Effect of Kn-2 on wheat seed germination under artificially simulated drought stress conditions

[0032] Dilute the Kn-2 preparation 200 times at room temperature at 20°C and soak the seeds for 12 hours. After drying, conduct a germination test on the seeds in a light incubator to simulate drought stress with PEG, and clean water is CK. Put the processed seeds into a petri dish, add 3mL concentration of -0.5MPa 19.2% PEG-6000 solution, count the germination potential, germination rate and relative germination rate of each treatment on the 3rd and 7th days of cultivation; Shoot length, primary root number and primary root length.

[0033] The results showed that the germination potential, germination rate, relative germination rate, primary root length and shoot length of wheat were improved or increased in different degrees after soaking seeds with Kn-2 formula. It shows that soaking seeds with Kn-2 preparation under drought stress improves the ability of see...

Embodiment 3

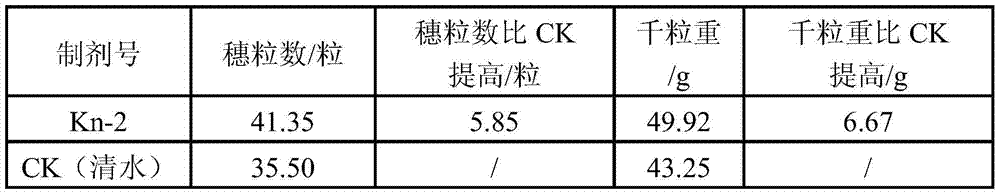

[0037] Example 3 Effect of Kn-2 formulation on thousand-grain weight and yield at the jointing stage of wheat, grouting and spraying (2012)

[0038]Spray 500 times of Kn-2 preparation once at the jointing stage and filling stage of wheat, set the same amount of water as CK, the tested variety: Shunmai 1718, and the location: Niujiaao Farm, Xia County, Cotton Research Institute, Shanxi Academy of Agricultural Sciences.

[0039] The results showed that the thousand-grain weight and yield of wheat sprayed with Kn-2 formula were higher than those of CK, which indicated that Kn-2 formula had better resistance to dry and hot wind. The results are shown in Table 2.

[0040] Table 2 Improvement of thousand-grain weight and yield of wheat by spraying anti-dry hot wind Kn-2 preparation

[0041] deal with Thousand grain weight (g) Yield per mu (Kg) Yield increase rate (%) Kn-2 36.68 562.8 13.2 CK (Shimizu) 35.66 513.4 /

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com