Combined drying technique for cowpeas

A technology combining drying and process methods, applied in the fields of food preparation, food science, preservation of fruits/vegetables by dehydration, etc., can solve the problems such as the loss of nutrients in the role of dehydrated cowpeas, and save conventional energy, improve efficiency, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

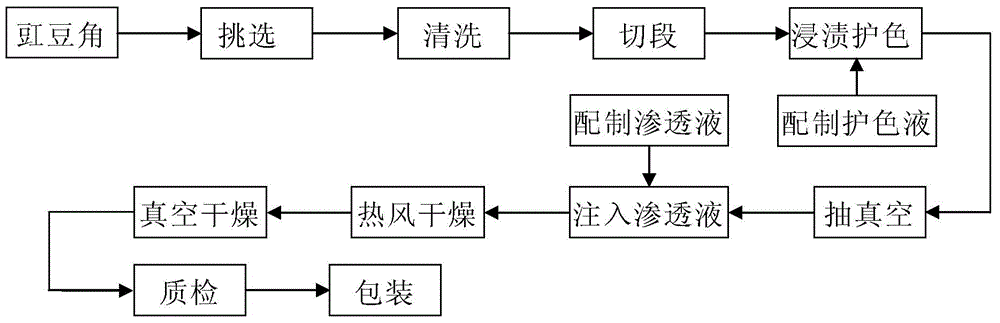

[0033] First buy fresh "Jinong 901 cowpea" variety of cowpea from the market, such as figure 1 As shown, the combined drying process is as follows:

[0034] Pretreatment: Choose cowpea with uniform thickness, no rot and no rust spots, and tender green flesh. Put the beans in clean water to wash them, then remove the shoots and roots of the kidney beans, and cut the remaining part into 5-6mm columnar sections, the shape and size should be basically the same.

[0035] Color protection treatment: configure color protection solution, with citric acid purity ≥99.5%, relative molecular mass 210.14, anhydrous calcium chloride purity 96.0%, relative molecular mass 110.99, vitamin C molecular formula, purity 99.7%, relative molecular mass 176.13 It is color protectant. According to the ratio of 1:5 solid-liquid color protection solution, the concentration of color protection agent in the color protection solution is 0.5% citric acid, 0.5% calcium chloride, 0.2% vitamin C, and then the cut...

Embodiment 2

[0041] First buy fresh "Jinong 901 cowpea" variety of cowpea from the market, such as figure 1 As shown, the combined drying process is as follows:

[0042] Pretreatment: Choose cowpea with uniform thickness, no rot and no rust spots, and tender green flesh. Put the beans in clean water to wash them, then remove the shoots and roots of the kidney beans, and cut the remaining part into 5-6mm columnar sections, the shape and size should be basically the same.

[0043] Color protection treatment: configure color protection solution, with citric acid purity ≥99.5%, relative molecular mass 210.14, anhydrous calcium chloride purity 96.0%, relative molecular mass 110.99, vitamin C molecular formula, purity 99.7%, relative molecular mass 176.13 It is color protectant. According to the ratio of 1:5 solid-liquid color protection solution, the concentration of color protection agent in the color protection solution is 0.5% citric acid, 0.5% calcium chloride, 0.2% vitamin C, and then the cut...

Embodiment 3

[0049] First buy fresh "Jinong 901 cowpea" variety of cowpea from the market, such as figure 1 As shown, the combined drying process is as follows:

[0050] Pretreatment: Choose cowpea with uniform thickness, no rot and no rust spots, and tender green flesh. Put the beans in clean water to wash them, then remove the shoots and roots of the kidney beans, and cut the remaining part into 5-6mm columnar sections, the shape and size should be basically the same.

[0051] Color protection treatment: configure color protection solution, with citric acid purity ≥99.5%, relative molecular mass 210.14, anhydrous calcium chloride purity 96.0%, relative molecular mass 110.99, vitamin C molecular formula, purity 99.7%, relative molecular mass 176.13 It is color protectant. According to the ratio of 1:5 solid-liquid color protection solution, the concentration of color protection agent in the color protection solution is 0.5% citric acid, 0.5% calcium chloride, 0.2% vitamin C, and then the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com