Ingredient for preparing beef jerky and preparation process

A technology of beef jerky and craftsmanship, which is applied in the field of food processing to achieve the effect of strong aroma, reduced peculiar smell, and appropriate salty taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

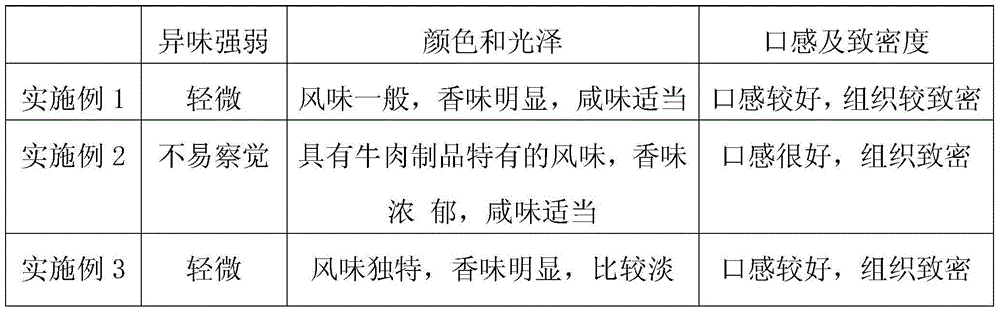

Examples

Embodiment 1

[0020] A beef jerky manufacturing process, characterized in that the ingredients are: ingredients 62%, salt 3%, soy sauce 2%, sugar 1.5%, spice concentrate 3%, sodium nitrate 0.05%, monosodium glutamate 0.05%, pepper Powder 0.2%, cooking wine 1%, the balance is water, the process of preparing beef jerky using the above ingredients, its specific steps are:

[0021] (1) Pretreatment of raw materials: select fresh beef hind legs, remove skin, bones, fat and tendons, divide into meat slices of about 0.2kg, wash and drain;

[0022] (2) Fermentation: After draining, put the fresh beef into the fermentation jar, inject the fermentation liquid, the ratio of beef to fermentation liquid is 1:3, seal the mouth of the jar with water, control the fermentation temperature at 20°C, and ferment for 20 hours;

[0023] (3) Pre-cooking: Take out the fermented meat pieces and wash them, put them into the pot, add water to completely submerge the meat pieces, and carry out pre-cooking. During the ...

Embodiment 2

[0030] A beef jerky manufacturing process, characterized in that the ingredients include: ingredients 75%, salt 3%, soy sauce 3%, sugar 3%, spice concentrate 6%, sodium nitrate 0.07%, monosodium glutamate 0.071%, pepper Powder 0.23%, cooking wine 1.5%, balance is water, utilizes the technology of above-mentioned batching to prepare beef jerky, and its specific steps are:

[0031] (1) Pretreatment of raw materials: select fresh beef hind legs, remove skin, bones, fat and tendons, divide into meat slices of about 0.3kg, wash and drain;

[0032] (2) Fermentation: After draining, put the fresh beef into the fermentation jar, inject the fermentation liquid, the ratio of beef to fermentation liquid is 1:3, seal the mouth of the jar with water, control the fermentation temperature at 30°C, and ferment for 12 hours;

[0033] (3) Pre-cooking: Take out the fermented meat pieces and wash them, put them into the pot, add water to completely submerge the meat pieces, and carry out pre-cook...

Embodiment 3

[0040] A beef jerky manufacturing process, characterized in that the ingredients include: ingredients 75%, salt 5%, soy sauce 3%, sugar 3.5%, spice concentrate 6%, sodium nitrate 0.1%, monosodium glutamate 0.1%, pepper Powder 0.25%, cooking wine 2%, the balance is water, utilize the technology of above-mentioned batching to prepare beef jerky, and its specific steps are:

[0041] (1) Pretreatment of raw materials: select fresh beef hind legs, remove the skin, bones, fat and tendons, divide into meat slices of about 0.5kg, wash and drain;

[0042] (2) Fermentation: After draining, put the fresh beef into the fermentation jar, inject the fermentation liquid, the ratio of beef to fermentation liquid is 1:3, seal the mouth of the jar with water, control the fermentation temperature at 30°C, and ferment for 24 hours;

[0043] (3) Pre-cooking: Take out the fermented meat pieces and wash them, put them into the pot, add water to completely submerge the meat pieces, and carry out pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com