Catalyst for synthesizing 1, 4-cyclohexanedimethanol and preparation method of catalyst

A technology of cyclohexanedimethanol and catalyst, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., and can solve the problems of short service life of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

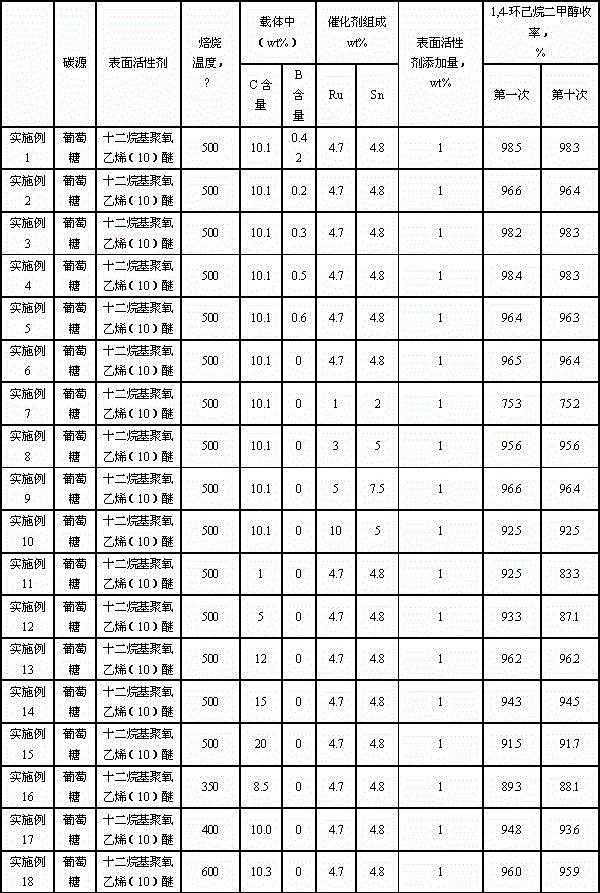

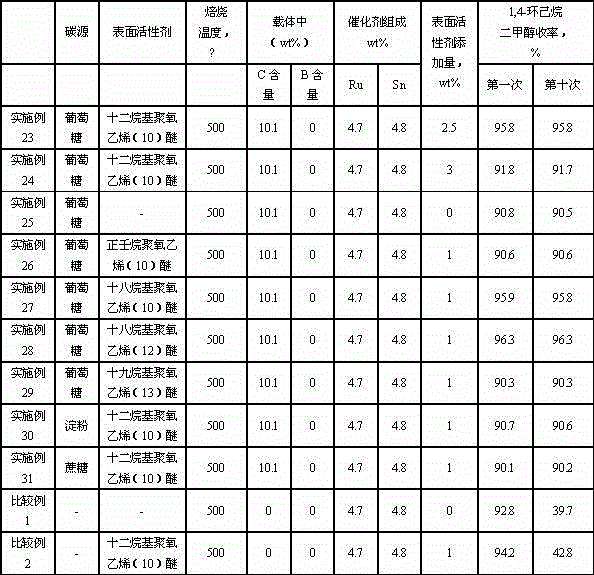

Examples

Embodiment 1

[0023] Carrier CAl 2 o 3 The preparation method is as follows: Take 50g Al 2 o 3- , and then follow the glucose and Al 2 o 3 The mass ratio of 0.65:1 prepares 100ml aqueous glucose solution, and 50g Al 2 o 3 And 1.5g of boric acid was added therein and soaked for 12h. After impregnation, dry in a vacuum oven at 90°C for 3h, and then bake at 500°C for 3h under the protection of nitrogen atmosphere to obtain the carrier CB-Al 2 o 3 , its carbon content was determined to be 10.1wt%, and its boron content was 0.42wt%.

[0024] Catalyst preparation method is as follows: 4.53gRuCl 3 ·3H 2 O was dissolved in 50ml of deionized water, then 3.91g of SnCl was added 2 2H 2 O dissolved, then add 35g carrier CB-Al 2 o 3 and 0.35 g of lauryl polyoxyethylene (10) ether were stirred evenly, left to age for 15 hours, and dried at 90° C. for 2 hours to obtain a catalyst precursor. The resulting precursor was then reduced for 3 hours in hydrogen diluted 7.5 times with nitrogen, the...

Embodiment 2-5

[0031] Change the input amount of boric acid to be 0.65g, 1.0g, 1.65g and 1.98g successively, and all the other operations are the same as embodiment 1. For convenience of comparison, the key experimental conditions used in each embodiment, the obtained catalyst composition and the catalyst evaluation obtained 1,4- The yields of cyclohexanedimethanol are listed in Table 1.

Embodiment 6

[0033] Carrier CAl 2 o 3 The preparation method is as follows: Take 50g Al 2 o 3- , and then follow the glucose and Al 2 o 3 The mass ratio of 0.65:1 prepares 100ml aqueous glucose solution, and 50g Al 2 o 3 Add it and soak for 12h. After impregnation, dry in a vacuum oven at 90°C for 3h, and then bake at 500°C for 3h under the protection of nitrogen atmosphere to obtain the carrier CAl 2 o 3, its carbon content was determined to be 10.1wt%.

[0034] Catalyst preparation method is as follows: 4.53gRuCl 3 ·3H 2 O was dissolved in 50ml of deionized water, then 3.91g of SnCl was added 2 2H 2 O dissolved, then add 35g carrier CAl 2 o 3 and 0.35 g of lauryl polyoxyethylene (10) ether were stirred evenly, left to age for 15 hours, and dried at 90° C. for 2 hours to obtain a catalyst precursor. The resulting precursor was then reduced for 3 hours in hydrogen diluted 7.5 times with nitrogen, the reduction temperature was 500°C, the hydrogen flow rate was 120ml / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com