Water painting device and water painting method for roll paper PUR (Polyurethane Rerctive) gum film laminator

A technology of roll paper and laminating machine, which is applied to the surface coating liquid device, coating, printing machine, etc., can solve the problems affecting the quality of the final product, shorten the delivery cycle, improve the quality, and speed up the moisture The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

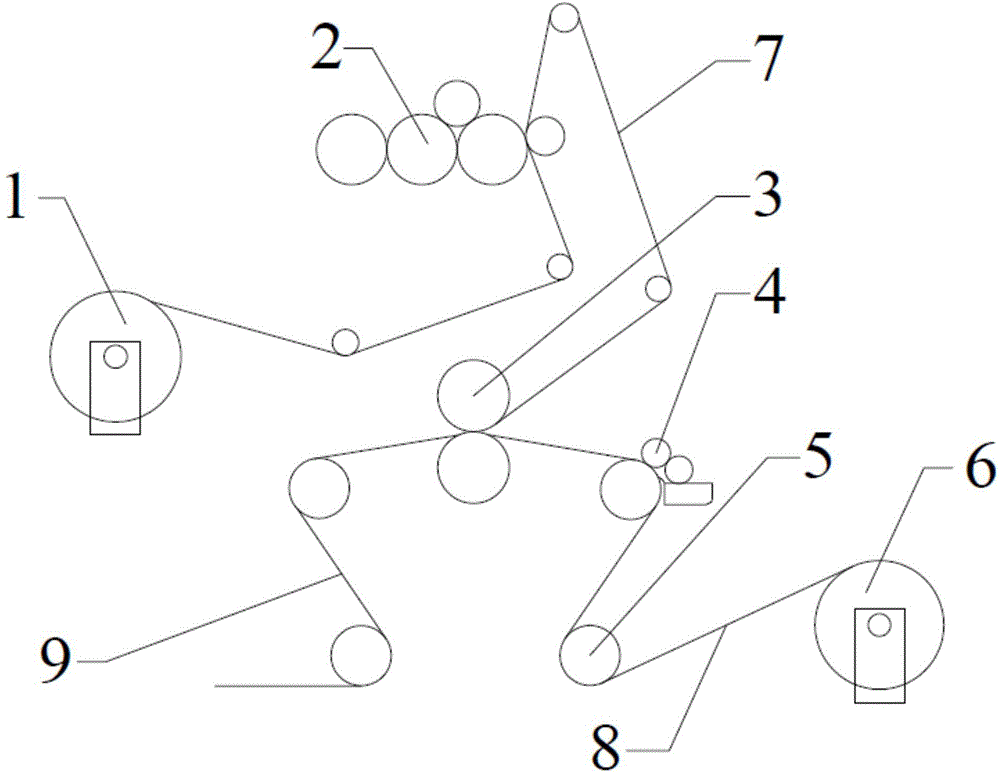

Image

Examples

Embodiment 1

[0031] A method for coating water with PUR glue on a web, using the water coating device of the above-mentioned PUR glue coating machine for web, specifically comprising the following steps:

[0032] The first step is to determine the humidity of the environment and the humidity of the material

[0033] Measure the air humidity S1 of the current working environment by a hygrometer to be 30%, and then measure the humidity S2 of the material to be composited. The humidity of the paper used in daily production is 6%, and S2 is 6% in the scheme of this application;

[0034] The second step is to determine the amount of water applied

[0035] According to the environmental humidity S1 measured in the first step is 30%, the material humidity S2 is 6%, and the amount of water applied M is determined to be 10g / cm 2 ;

[0036] The third step is to apply water

[0037] Place the composite material on the second unwinding mechanism 6, when the composite material passes through the wat...

Embodiment 2

[0039] A method for coating water with PUR glue on a web, using the water coating device of the above-mentioned PUR glue coating machine for web, specifically comprising the following steps:

[0040] The first step is to determine the humidity of the environment and the humidity of the material

[0041] Measure the air humidity S1 of the current working environment by a hygrometer to be 40%, and then measure the humidity S2 of the material to be composited;

[0042] The second step is to determine the amount of water applied

[0043] According to the environmental humidity S1 measured in the first step is 40%, the material humidity S2 is 6%, and the amount of water applied M is determined to be 8g / cm 2 ;

[0044] The third step is to apply water

[0045] Place the composite material on the second unwinding mechanism 6, when the composite material passes through the water application mechanism 4, apply water to the composite material by the water application mechanism 4, and...

Embodiment 3

[0047] A method for coating water with PUR glue on a web, using the water coating device of the above-mentioned PUR glue coating machine for web, specifically comprising the following steps:

[0048] The first step is to determine the humidity of the environment and the humidity of the material

[0049] Measure the air humidity S1 of the current working environment by a hygrometer to 50%, and then measure the humidity S2 of the material to be composited;

[0050] The second step is to determine the amount of water applied

[0051] According to the environmental humidity S1 measured in the first step is 50%, the material humidity S2 is 6%, and the amount of water applied M is determined to be 6g / cm 2 ;

[0052] The third step is to apply water

[0053] Place the composite material on the second unwinding mechanism 6, when the composite material passes through the water application mechanism 4, apply water to the composite material by the water application mechanism 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com