Method for preparing rare earth ion co-doped optical fiber preform

A technology of optical fiber preform and rare earth ions, which is applied in the field of optical fiber manufacturing technology, can solve the problems of preparing gradient rare earth doped optical fiber, and achieve the effect of reducing research and development costs and improving scientific research efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

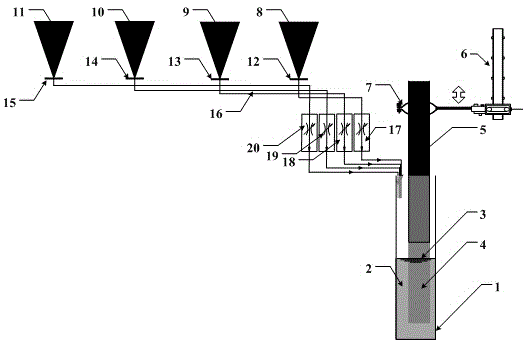

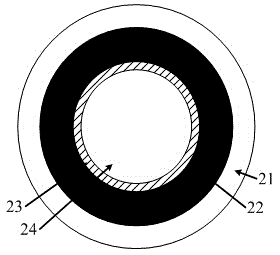

[0019]Embodiment 1: This embodiment is suitable for making optical fiber preforms with different ion co-doping ratios in the axial direction. For ease of understanding, this embodiment takes the production process of a relatively common erbium-ytterbium co-doped optical fiber preform as an example for illustration. Firstly, a preformed rod containing a loose core layer is deposited by MCVD technology. After the deposition is completed, the preformed rod 4 connected with the support tube 5 is removed and fixed on the electronically controlled precision lifting device 6 through the clamp 7 . Inject ytterbium ion solution, erbium ion solution, aluminum ion solution and deionized water into the first conical glass container 8, the second conical glass container 9, the third conical glass container 10 and the fourth conical glass container 11 respectively , then open the first switch 12, the second switch 13, the third switch 14 and the fourth switch 15, and control the first flowm...

Embodiment 2

[0021] Embodiment 2: This embodiment is suitable for making optical fiber preforms with the same ion co-doping ratio and different doping concentrations in the axial direction. Firstly, a preformed rod containing a loose core layer is deposited by MCVD technology. After the deposition is completed, the preformed rod 4 connected with the support tube 5 is removed and fixed on the electronically controlled precision lifting device 6 through the clamp 7 . In the first conical glass container 8, the second conical glass container 9, the third conical glass container 10 and the fourth conical glass container 11, respectively inject A kind of rare earth ion solution, B kind of rare earth ion solution, co-doped ion Solution and deionized water, then open the first switch 12, the second switch 13, the third switch 14 and the fourth switch 15, and control the first flowmeter 17, the second flowmeter 18, the third flowmeter by controlling the opening time of the switch The flowmeter 19 ...

Embodiment 3

[0022] Embodiment 3: This embodiment is suitable for making a gradient-doped rare earth optical fiber preform. Firstly, a preformed rod containing a loose core layer is deposited by MCVD technology. After the deposition is completed, the preformed rod 4 connected with the support tube 5 is removed and fixed on the electronically controlled precision lifting device 6 through the clamp 7 . In the first conical glass container 8, the second conical glass container 9, the third conical glass container 10 and the fourth conical glass container 11, respectively inject A kind of rare earth ion solution, B kind of rare earth ion solution, co-doped ion Solution and deionized water, then open the first switch 12, the second switch 13, the third switch 14 and the fourth switch 15, and control the first flowmeter 17, the second flowmeter 18, the third flowmeter by controlling the opening time of the switch The flowmeter 19 and the fourth flowmeter 20 are connected to the four tapered glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com