Alpha-gypsum and production method thereof

A technology of gypsum and desulfurized gypsum, applied in the field of α-gypsum and its production, can solve the problems of low strength of gypsum products, poor crystallinity and morphology of α-gypsum, narrow application range, etc., and achieve small linear variation and good fluidity , high precision effect

Inactive Publication Date: 2015-04-29

赵云龙 +1

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] However, in the method of the above-mentioned prior art, the grade requirement of the raw material is higher, resulting in a narrower scope of application of the method, and the crystallinity and morphology of α-gypsum (that is, α-hemihydrate gypsum) are generally poor, resulting in The strength of the prepared gypsum product is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0047] Comparative example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending resistance | aaaaa | aaaaa |

Login to View More

Abstract

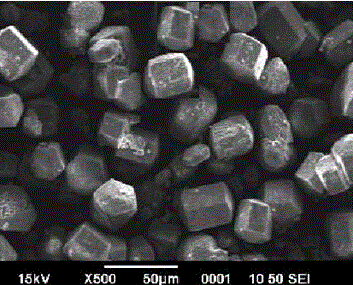

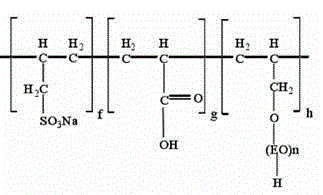

The invention discloses alpha-gypsum and a production method thereof. The production method comprises the following steps: mixing desulfurization gypsum or citric acid gypsum and water according to a specified ratio, pulping, thereby obtaining slurry; carrying out a hydrothermal reaction on the slurry; dehydrating and drying on the reactants, thereby obtaining the finished product, namely high-strength super-hard alpha-gypsum. The produced high-strength super-hard alpha-gypsum can be made into multiple high-grade gypsum molds or high-grade buildings and decorative materials and has the advantages of high liquidity, high simulation ability, high strength, smooth surface and the like.

Description

technical field [0001] The invention relates to α-gypsum and a production method thereof, in particular to a high-strength superhard α-gypsum and a production method thereof. technical background [0002] At present, my country has become the country with the largest emission of sulfur dioxide, most of which are emitted by thermal power plants. my country's coal-fired power plants account for more than half of the country's total sulfur dioxide emissions, making them major emitters of sulfur dioxide. Limestone / lime wet flue gas desulfurization method is currently the most important method for removing sulfur dioxide. This method produces a large amount of solid residue mainly composed of calcium sulfite. Because calcium sulfite is unstable, it cannot It is easily oxidized to calcium sulfate, and its crystal form is similar to gypsum, that is, flue gas desulfurization gypsum. In power plants equipped with desulfurization devices, flue gas desulfurization gypsum is increasin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B11/26

Inventor 赵云龙康建红

Owner 赵云龙

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com