Process for preparing unsaturated esters

A compound and solvent technology, applied in the field of preparing 4-methyl-6-hex-3-alkenoic acid alkyl ester, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

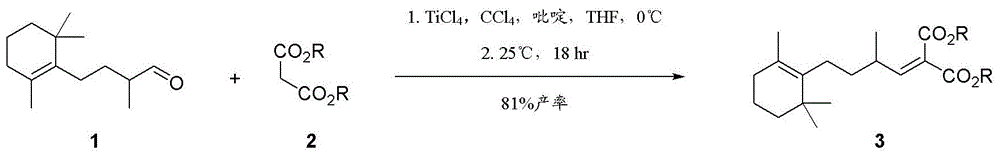

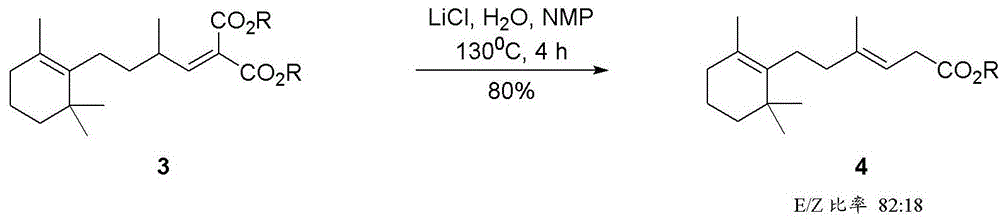

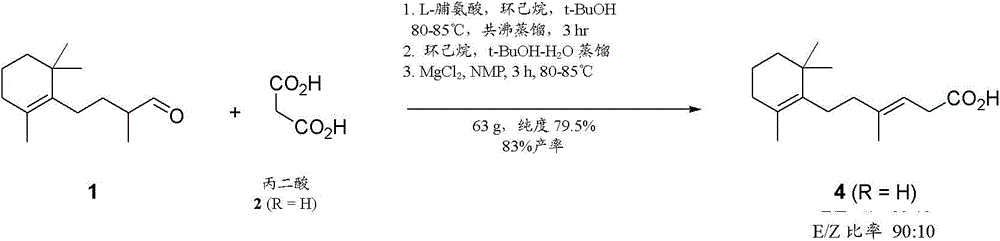

Method used

Image

Examples

Embodiment 1

[0035] Preparation of high E ethyl 4-methyl-6-(2,6,6-trimethylcyclohex-1-en-1-yl)hex-3-enoate (4, R=ethyl).

[0036] While stirring, 2-methyl-4-(2,6,6-trimethylcyclohex-1-en-1-yl)butanal (1) (10 g, 79% purity), dimethylethyl Amide (12 g), monoethyl malonate (8 g, Alfa Aesar 96% purity) and MgCl 2 (2.75g Sigma, anhydrous, >98%) was heated to 120°C and then stirred at this temperature for 2 hours. The yield in terms of purity according to GC analysis was 81% for the E-4 isomer and 11% for the Z-4 isomer (ratio E / Z=88:12). The sum of the isomers was 75% based on the internal standard.

[0037] Cool the reaction mixture to 60 °C and separate the lower MgCl 2 - DMAC phase, the organic phase is washed with water and distilled at 120-130° C. / 0.1 mm.

[0038] After distillation, the E isomer content was 71% and the Z isomer content was 9.5%.

Embodiment 2

[0040] Preparation of high E ethyl 4-methyl-6-(2,6,6-trimethylcyclohex-1-en-1-yl)hex-3-enoate (4, R=ethyl).

[0041] 2-Methyl-4-(2,6,6-trimethylcyclohex-1-en-1-yl)butanal (1) (10g, 79% purity), dimethylacetamide (10g) , monoethyl malonate (5.5 g) and LiCl (2 g) were heated to 130° C. for 1 hour. Monoethyl malonate (9 g) was then added at 130°C for 3 hours. The reaction mixture was cooled and stirred with water (50 g) and hexane (15 ml). The organic phase was separated and washed 3 times with 20 ml of water, then the solvent was evaporated under reduced pressure to provide a compound containing 52% E-4 isomer, 9.5% Z-4 isomer and 10% conjugated isomer 6 according to GC analysis. 12g of crude product. The yield of the E isomer was 59% in purity.

Embodiment 3

[0043] Preparation of 4-methyl-6-(2,6,6-trimethylcyclohex-1-en-1-yl)hex-3-enoic acid (4, R=H) with high E

[0044] 2-Methyl-4-(2,6,6-trimethylcyclohex-1-en-1-yl)butanal (1) (10g, 79% purity), dimethylacetamide (12g) , malonic acid (8g) and MgCl 2 (3 g) was heated to 130°C and held for 2 hours.

[0045] According to GC analysis, the reaction mixture contained 39.6% of E-monocyclic homofarnesic acid (4, R=H) and 14.5% of the corresponding Z-4 isomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com