High-concentration organic wastewater treatment process

A technology for organic wastewater treatment and organic wastewater, which is applied in the field of high-concentration organic wastewater treatment technology and can solve problems such as unsatisfactory treatment effect, changes in wastewater components, and unfavorable biological reaction bacterial growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

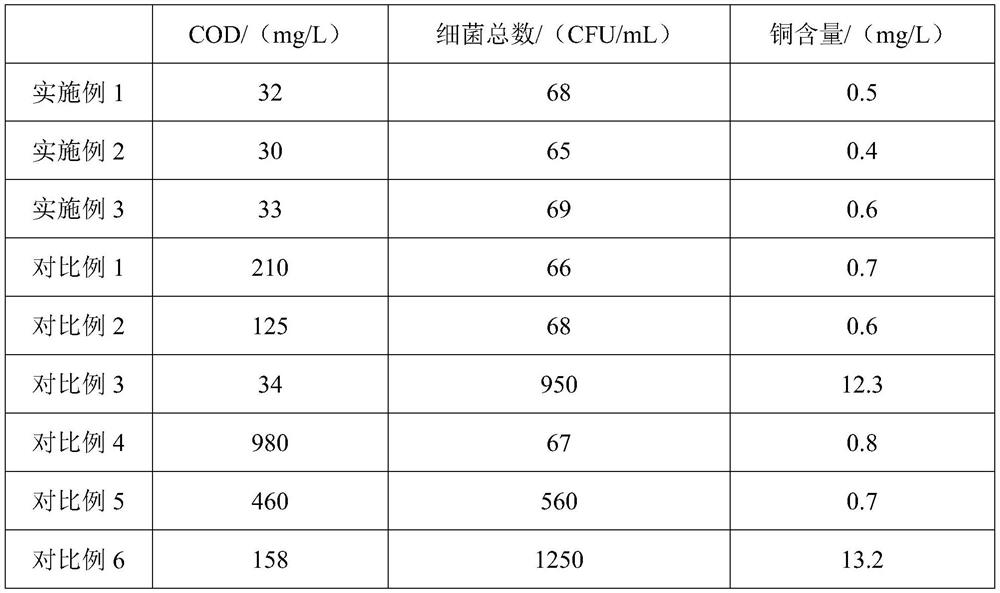

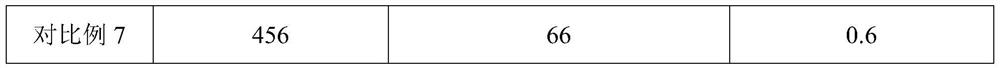

Examples

Embodiment 1

[0031] A high-concentration organic wastewater treatment process, the high-concentration organic wastewater treatment process comprises the following steps:

[0032] (1) At 69°C, mix carbon nanotubes and nitric acid solution with a mass fraction of 66% in a mass ratio of 1:0.3, stir and reflux at 1200r / min for 23h, wash with deionized water for 3 times and filter, Vacuum dry at 58°C for 23 hours to obtain acidified carbon nanotubes; then mix the acidified carbon nanotubes, ethylenediamine, and dicyclohexylcarbodiimide at a mass ratio of 1:0.1:15, and put them in an oil bath at 118°C In the pot, stir and reflux at 1200r / min for 95h, wash with absolute ethanol for 3 times, filter, and vacuum dry at 10Pa, 58°C for 23h to prepare functionalized carbon nanotubes; at 25°C, functionalized carbon nanotubes , toluene and dipentylenedione-based isopentyl glycol were mixed at a mass ratio of 1:5:0.6, stirred at 1200r / min for 30min, heated to 110°C at 1°C / min, continued to stir for 6h, an...

Embodiment 2

[0040] A high-concentration organic wastewater treatment process, the high-concentration organic wastewater treatment process comprises the following steps:

[0041] (1) At 70°C, mix carbon nanotubes and nitric acid solution with a mass fraction of 68% at a mass ratio of 1:0.35, stir and reflux at 1250r / min for 24h, wash with deionized water for 3 times and filter, Vacuum dry at 60°C for 24 hours to obtain acidified carbon nanotubes; then mix the acidified carbon nanotubes, ethylenediamine, and dicyclohexylcarbodiimide at a mass ratio of 1:0.125:16, and put them in an oil bath at 120°C In the pot, stir and reflux at 1250r / min for 96h, wash with absolute ethanol for 3 times, filter, and vacuum dry at 15Pa and 60°C for 24h to prepare functionalized carbon nanotubes; at 25.5°C, functionalized carbon nanotubes , toluene and dipentylenedione-based isopentyl glycol were mixed at a mass ratio of 1:6:0.7, stirred at 1250r / min for 35min, heated to 111°C at 2°C / min, continued to stir fo...

Embodiment 3

[0049] A high-concentration organic wastewater treatment process, the high-concentration organic wastewater treatment process comprises the following steps:

[0050] (1) At 71°C, mix carbon nanotubes and nitric acid solution with a mass fraction of 70% at a mass ratio of 1:0.4, stir and reflux at 1300r / min for 25h, wash with deionized water for 4 times and filter, Dry in vacuum at 62°C for 25 hours to obtain acidified carbon nanotubes; then mix the acidified carbon nanotubes, ethylenediamine, and dicyclohexylcarbodiimide in a mass ratio of 1:0.15:17, and put them in an oil bath at 122°C In the pot, stir and reflux at 1300r / min for 97h, wash with absolute ethanol for 4 times, filter, and vacuum dry at 20Pa and 62°C for 25h to prepare functionalized carbon nanotubes; at 26°C, functionalized carbon nanotubes , toluene and dipentylenedione-based isopentyl glycol were mixed at a mass ratio of 1:7:0.8, stirred at 1300r / min for 40min, heated to 112°C at 3°C / min, continued to stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com