Primer for bonding silicon rubber to polyamide material and preparation method of primer

A technology of polyamide and primer, which is applied in the field of silicone rubber, can solve the problems of poor bonding effect with PA and poor storage stability, and achieve the effect of improving bonding and excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of preparation method of the primer of silicone rubber and polyamide material bonding, and this method comprises the following steps:

[0031] S1. To prepare component A, add orthosilicate to the first solvent, and stir for 5-10 minutes; add titanate under stirring, and stir for 5-10 minutes; add silane coupling agent under stirring, and stir for 5 minutes -10min; add high hydrogen-containing siloxane under stirring state, and keep stirring for 30-60min; after static aging reaction, component A of the primer is obtained;

[0032] S2. Prepare component B, add polyamide oligomer to the second solvent, and stir to obtain component B;

[0033] S3, preparing a primer, mixing and stirring component A and component B to obtain a primer bonded with silicone rubber and polyamide materials;

[0034] Wherein, the total amount of the first solvent and the second solvent is 100 parts by weight, the polyamide oligomer is 0.05-5 parts by wei...

Embodiment 1

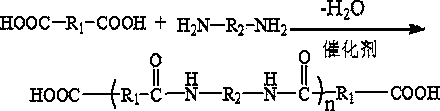

[0047] Preparation of polyamide oligomers:

[0048] Add 20.0g of hexamethylenediamine, 40.3g of adipic acid (amine:acid=0.625:1) and 0.1g of catalyst BC-98 in a 150mL three-neck flask equipped with a water separator, reflux condenser, stirrer and thermometer, Under the protection of N2, slowly raise the temperature to 100°C, start slow stirring, slowly raise the temperature to 150°C, keep warm for 2 hours, add 0.1g heat stabilizer TP2Pi, then raise the temperature to 200°C at a uniform speed within 2 hours, keep warm for 1h, Polyamide oligomer S1 was obtained.

Embodiment 2

[0050] Polyamide oligomer preparation:

[0051] Add 10.0g hexamethylenediamine, 10.0g o-phenylenediamine, 50.5g sebacic acid (amine:acid=0.71:1) and 0.12g of catalyst BC-98, under the protection of N2, slowly raise the temperature to 120°C, start to stir slowly, slowly raise the temperature to 160°C, keep it warm for 1h, add 0.15g of heat stabilizer TP2Pi, and then raise the temperature at a constant speed within 1h to 190° C. and keep it warm for 2 hours to obtain polyamide oligomer S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com