Method for bonding uranium tailing slag by using carbon-nano-material-immobilized mineralization bacterium

A technology of carbon nanomaterials and tailings slag, which is applied in the field of solidification treatment of radioactive waste, can solve the problems that there are few treatment methods for uranium tailings slag, and there are no literature reports on uranium tailings slag cemented by carbon nanomaterials and mineralization bacteria. Diffusion and loss, effect of good adsorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

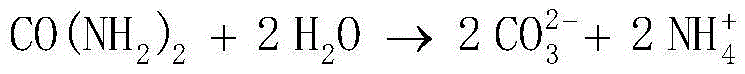

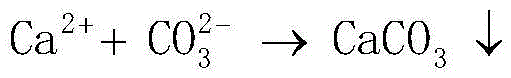

Method used

Image

Examples

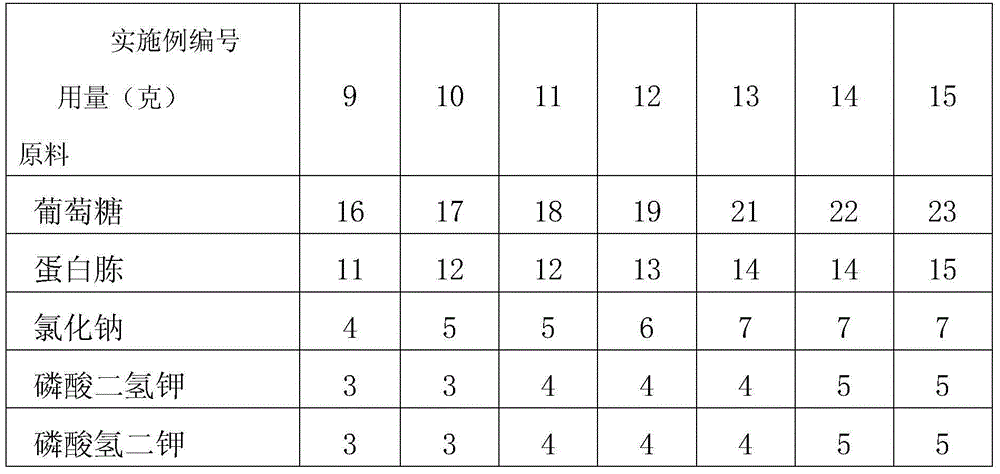

Embodiment 1

[0026] Take 100 grams of uranium tailings, add 5 milliliters of carbon fiber aqueous solution with a concentration of 1 mg per milliliter to the uranium tailings, mix well, and let stand for 24 hours. Put a layer of filter paper at the bottom of the test mold (which can be a cylindrical mold with an upper end and a hole in the bottom), put the uranium tailings into the test mold, and put another layer of filter paper on the uranium tailings to play a buffering role. Bacillus sarcina was expanded and cultivated in the liquid culture solution, and the composition and content of each liter of the liquid culture solution were: 20 grams of glucose, 12 grams of peptone, 5 grams of sodium chloride, 3 grams of potassium dihydrogen phosphate, dihydrogen phosphate 3 grams of potassium; the pH of the liquid culture solution is 8.0. Cultivate at 30°C for 24 hours, and centrifuge the bacterial liquid at 4000 rpm for 20 minutes to obtain concentrated bacterial liquid. Use a peristaltic pum...

Embodiment 2

[0029]Take 100 grams of uranium tailings, add 10 milliliters of carbon fiber aqueous solution with a concentration of 1 mg per milliliter to the uranium tailings, mix well, and let stand for 24 hours. Put a layer of filter paper at the bottom of the test mold (which can be a cylindrical mold with an upper end and a hole in the bottom), put the uranium tailings into the test mold, and put another layer of filter paper on the uranium tailings to play a buffering role. Bacillus sarcina was expanded and cultivated in the liquid culture solution, and the composition and content of each liter of the liquid culture solution were: 20 grams of glucose, 11 grams of peptone, 5 grams of sodium chloride, 3 grams of potassium dihydrogen phosphate, dihydrogen phosphate 3 grams of potassium; the pH of the liquid culture solution is 8.0. Cultivate at 30°C for 24 hours, and centrifuge the bacterial liquid at 4000 rpm for 20 minutes to obtain concentrated bacterial liquid. Use a peristaltic pum...

Embodiment 3

[0032] Take 100 grams of uranium tailings, add 8 milliliters of carbon fiber aqueous solution with a concentration of 1 mg per milliliter to the uranium tailings, mix well, and let stand for 24 hours. Put a layer of filter paper at the bottom of the test mold (which can be a cylindrical mold with an upper end and a hole in the bottom), put the uranium tailings into the test mold, and put another layer of filter paper on the uranium tailings to play a buffering role. Bacillus sarcina was expanded and cultivated in liquid culture medium, and the composition and content of each liter of liquid culture medium were: 20 grams of glucose, 11 grams of peptone, 5 grams of sodium chloride, 4 grams of potassium dihydrogen phosphate, dihydrogen phosphate Potassium 4 grams; the pH value of the liquid culture solution is 7.0. Cultivate at 30°C for 24 hours, and centrifuge the bacterial liquid at 4500 rpm for 30 minutes to obtain concentrated bacterial liquid. Use a peristaltic pump to inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com