Cesium tungsten-tellurite crystal as well as flux growth method and application thereof

A technology of crystal growth and flux, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of crystal quality and unsuccessful analysis of crystal structure, and achieve the effect of wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

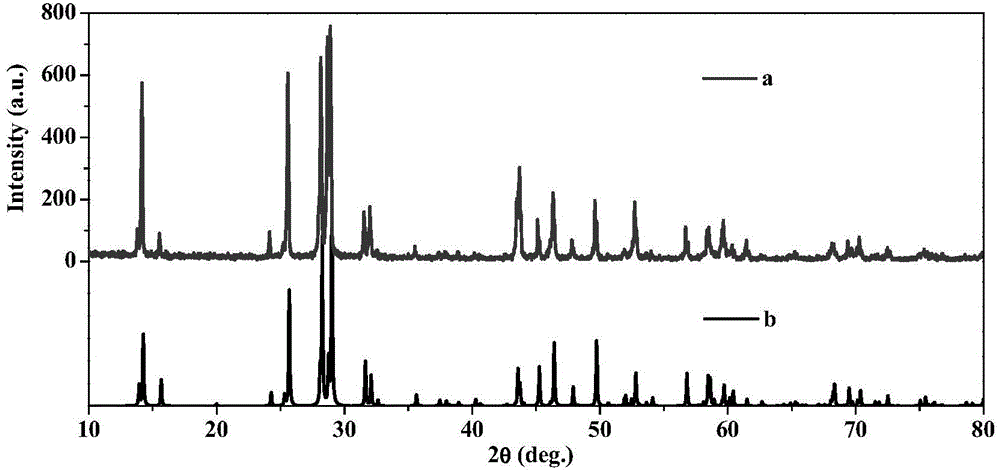

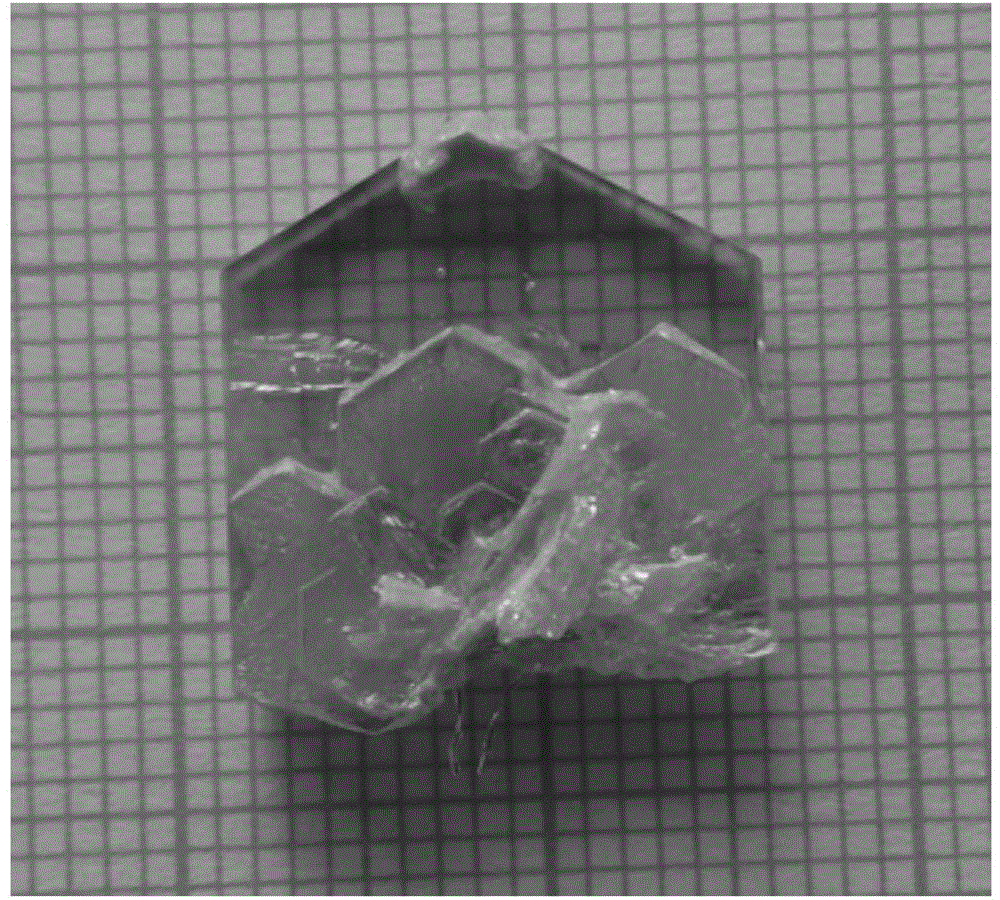

[0054] Cs 2 CO 3 , TeO 2 and WO 3 Ingredients according to stoichiometric ratio, mixed evenly, directly added to the flux system TeO 2 -WO 3 (TeO 2 : WO 3 The molar ratio is 2:2.5), the Cs 2 CO 3 , TeO 2 、WO 3 The molar ratio to the total compound in the flux is 1:1:3:1, put it into a platinum crucible with a volume of Φ50mm×70mm, raise the temperature to 750°C to melt the raw material and form a uniform melt; cool down to the saturation point, at this time The preheated platinum wire was lowered, and the temperature was lowered at a cooling rate of 1°C / h, and the growth cycle was 10 days. It was proposed that the platinum wire could obtain multiple light yellow flaky crystals ( image 3 ), there are more miscellaneous crystals in the contact with the platinum wire, because there are more nucleation points here, which are easy to generate miscellaneous crystals, and the crystal quality is obviously better at the place far away from the platinum wire. Test its X-ray ...

Embodiment 2

[0057] Cs 2 CO 3 , TeO 2 and WO 3 Ingredients according to stoichiometric ratio, mixed evenly, directly added to the flux system TeO 2 -WO 3 (TeO 2 : WO 3 The molar ratio is 2:2.5), the Cs 2 CO 3 , TeO 2 、WO 3 The molar ratio to the total compound in the flux is 1:1:3:3, put it into a platinum crucible with a volume of Φ50mm×70mm, raise the temperature to 750°C to melt the raw material and form a uniform melt; cool down to the saturation point, at this time Put the preheated seed crystal (taken from Example 1) into the melt, and lower the temperature at a cooling rate of 0.5°C / h. The growth cycle is 20 days, and a light yellow block single crystal ( Figure 4 ), test its X-ray diffraction pattern, it is consistent with the theoretical calculation, and it is proved that the cesium telluride tungstate crystal of the hexagonal system is obtained.

[0058] The single crystal cesium telluride tungstate obtained in Example 2 is oriented processed into flakes of required s...

Embodiment 3

[0061] Cs 2 CO 3 , TeO 2 and WO 3 Ingredients according to stoichiometric ratio, mixed evenly, directly added to the flux system TeO 2 -WO 3 (TeO 2 : WO 3 The molar ratio is 2:3), the Cs 2 CO 3 , TeO 2 、WO 3 The molar ratio to the total compound in the flux is 1:1:3:5, put it into a platinum crucible with a volume of Φ50mm×70mm, raise the temperature to 750°C to melt the raw materials and form a uniform melt; cool down to the saturation point, at this time Put the preheated seed crystal into the melt, and lower the temperature at a cooling rate of 0.3°C / h. The growth cycle is 30 days, and a light yellow block single crystal ( Figure 5 ), test its X-ray diffraction pattern, it is consistent with the theoretical calculation, and it is proved that the cesium telluride tungstate crystal of the hexagonal system is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com