Method for judging blockage of line chip filter of clothes drying machine and clothes drying machine

A lint filter and clothes dryer technology, applied in the field of clothes dryers, can solve problems such as the influence of environmental temperature changes, long judgment time, etc., and achieve the effects of energy saving, short time, and no time retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

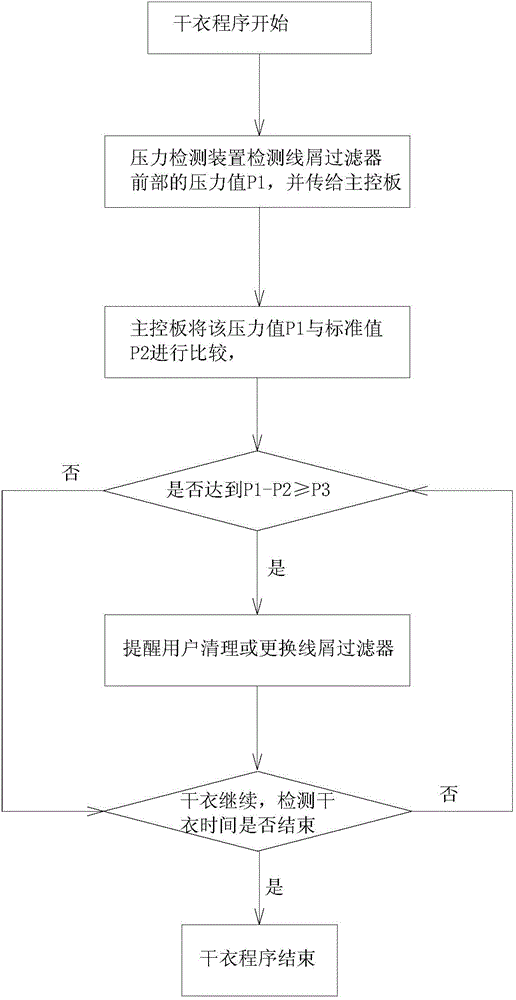

Embodiment 1

[0050] When the pressure is detected, the pressure is connected with the frequency of the oscillating circuit, and the pressure is detected by the frequency change measured by the test circuit. The principle of pressure detection by the pressure detection device is: use the catheter to introduce the air at the measurement point into the air chamber. When the air pressure increases, the diaphragm in the air chamber drives the spring and the iron core to move under the pressure. When the air pressure decreases, the spring Push the diaphragm to move in the opposite direction. Use the position change of the iron core to change the inductance in the LC oscillating circuit to change the frequency of the oscillating circuit, and establish a relationship between the air pressure and the frequency of the oscillating circuit:

[0051] f=1 / [2*π*SQRT(L*C)], the pressure can be judged by the frequency difference measured by the test circuit.

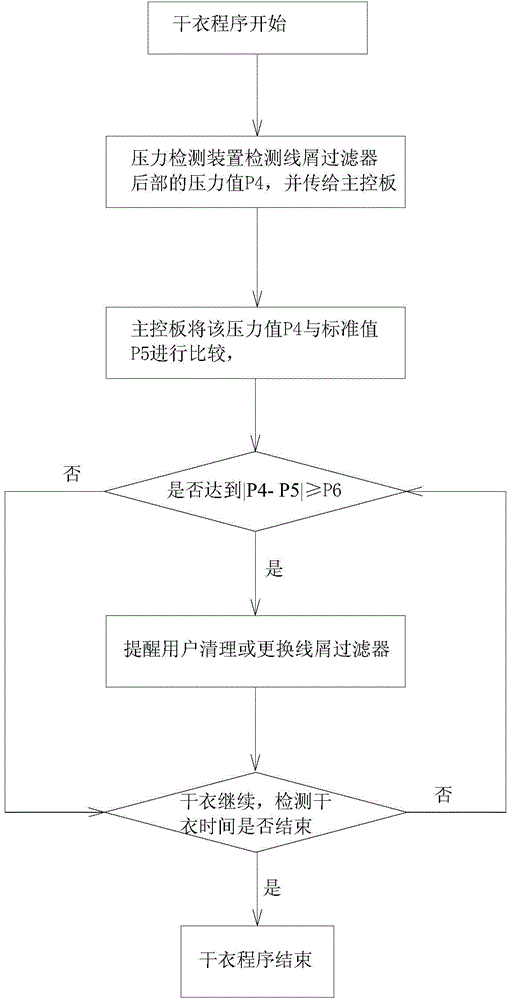

Embodiment 2

[0053] According to this embodiment, a clothes dryer using the above judgment method includes a drying air duct and a lint filter in the drying air duct, and a pressure detection device is also installed in the drying air duct, and the pressure detection device It includes a pressure sensor for detecting the pressure at the front of the lint filter and / or a pressure sensor for detecting the pressure at the rear of the lint filter, and the pressure sensor is an inductive pressure sensor. The pressure sensor is connected with the main control board of the clothes dryer, and transmits the detected pressure signal to the main control board.

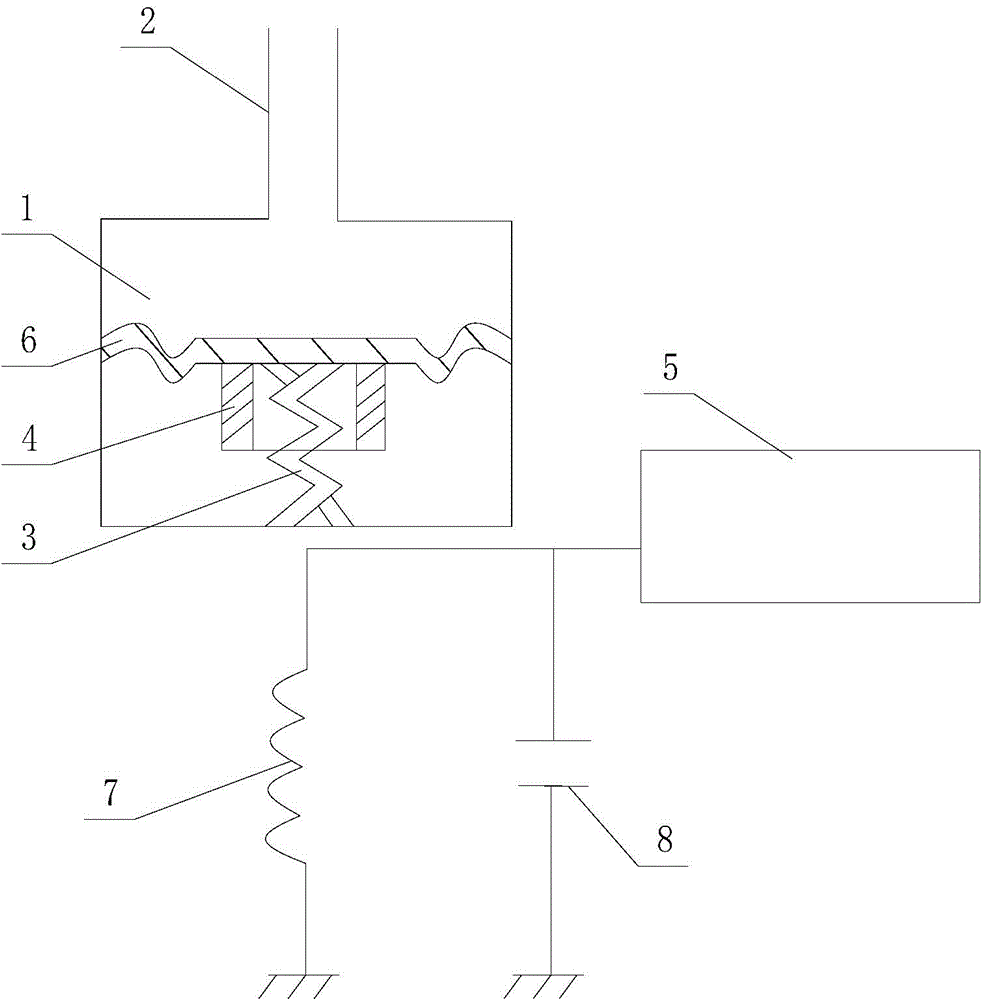

[0054] like figure 1 As shown, the pressure sensor includes a gas chamber 1, a diaphragm 6 and an iron core 4 in the gas chamber 1, a spring 3 connected to the diaphragm 6, and the diaphragm 6 is slidably connected to the inner wall of the gas chamber 1, but is sealed. connected, the iron core 4 is fixed on the diaphragm 6, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com