Steel-mesh-containing vacuum thermal insulation insulating layer and insulating system for building and construction method of insulating layer and insulating system

A technology of vacuum insulation and vacuum insulation panels, which is applied in the directions of thermal insulation, building components, and insulation improvement, can solve problems such as poor thermal insulation effect, and achieve the effects of excellent thermal insulation and fire resistance, thinning thickness, and load reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following is a detailed description of the present invention in combination with specific implementation cases.

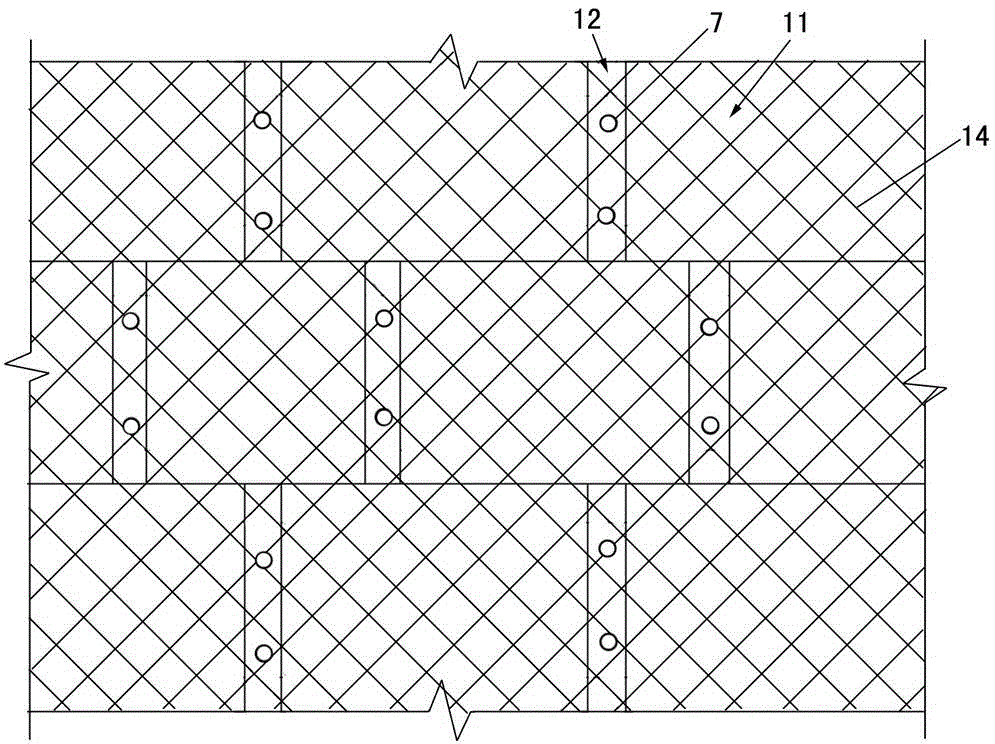

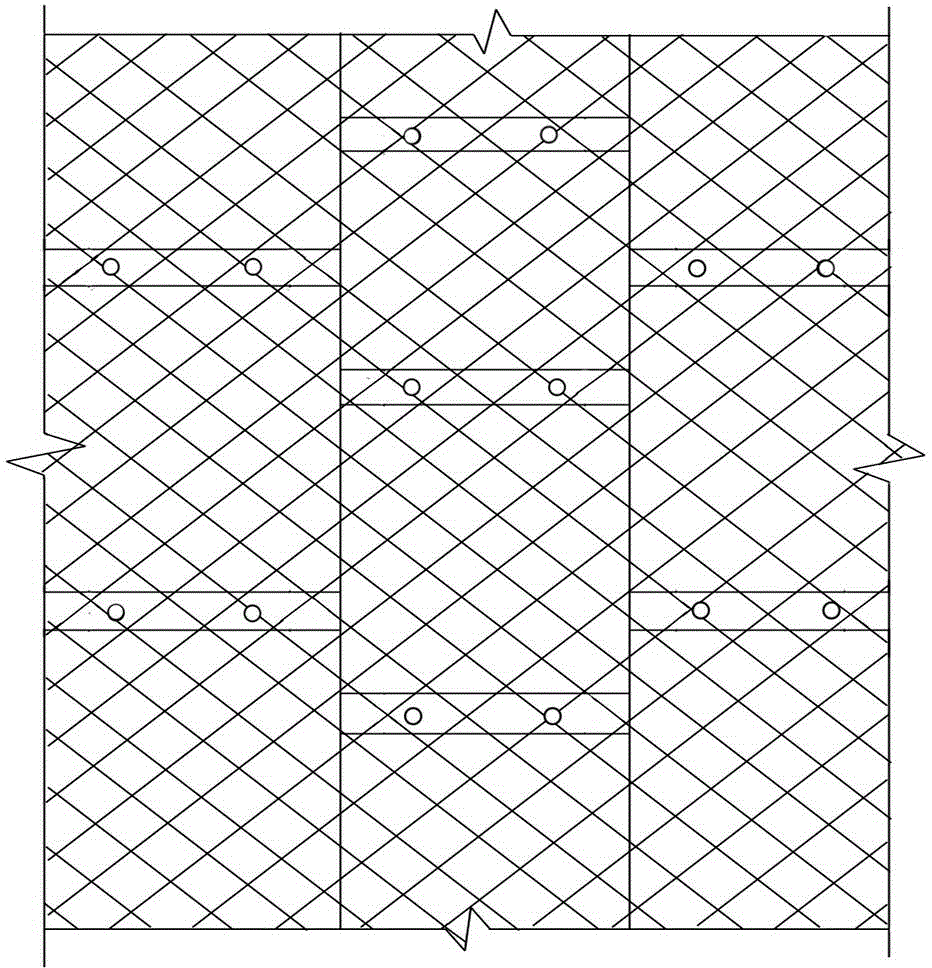

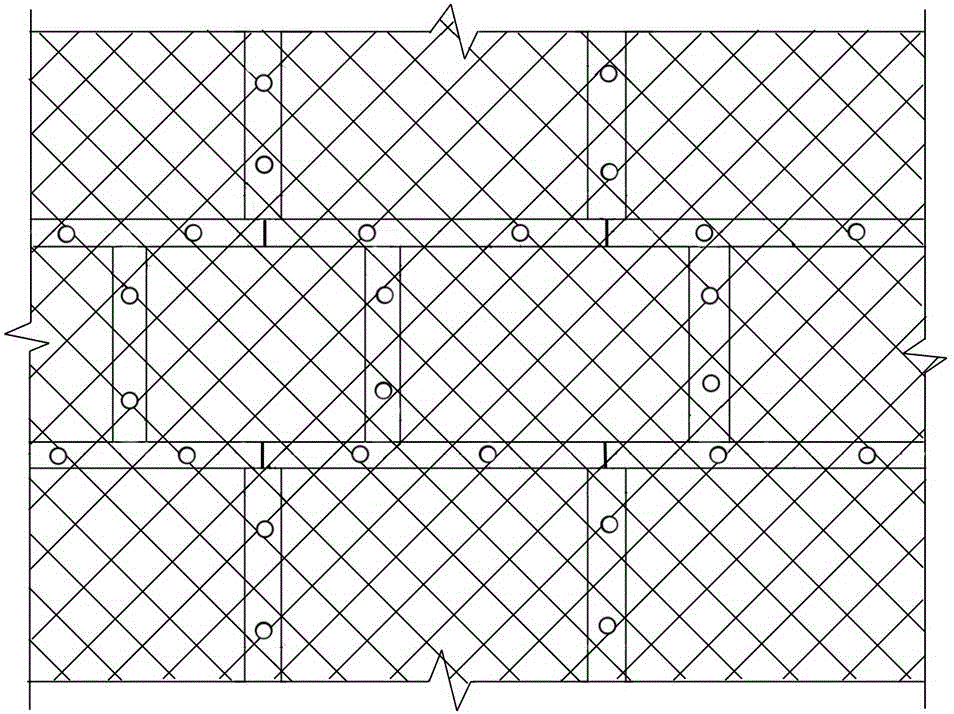

[0058] participate figure 1 , Figure 4-10 , The first building vacuum insulation layer 4 containing steel mesh, including a building vacuum insulation board 11 and a building vacuum insulation strip 12, the building vacuum insulation board 11 is covered by a thermal insulation core material 8 The vacuum package 9 is evacuated and hot-pressed and sealed into a square plate shape, and the building vacuum insulation strip 12 is made of a thermal insulation core material 8 and wrapped in a composite vacuum package 9 that is evacuated and hot-pressed and sealed into a strip shape. In addition, the width of the building vacuum insulation strip 12 is consistent with the distance between the two building vacuum insulation panels after they are attached to the wall.

[0059] In the construction vacuum heat insulation layer 4 containing steel mesh, the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com