Pressure-controlled gas drilling device and method

A technology of gas drilling and gas flow, which can be applied in the direction of drilling with liquid/gas jets, etc., and can solve problems such as formation water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

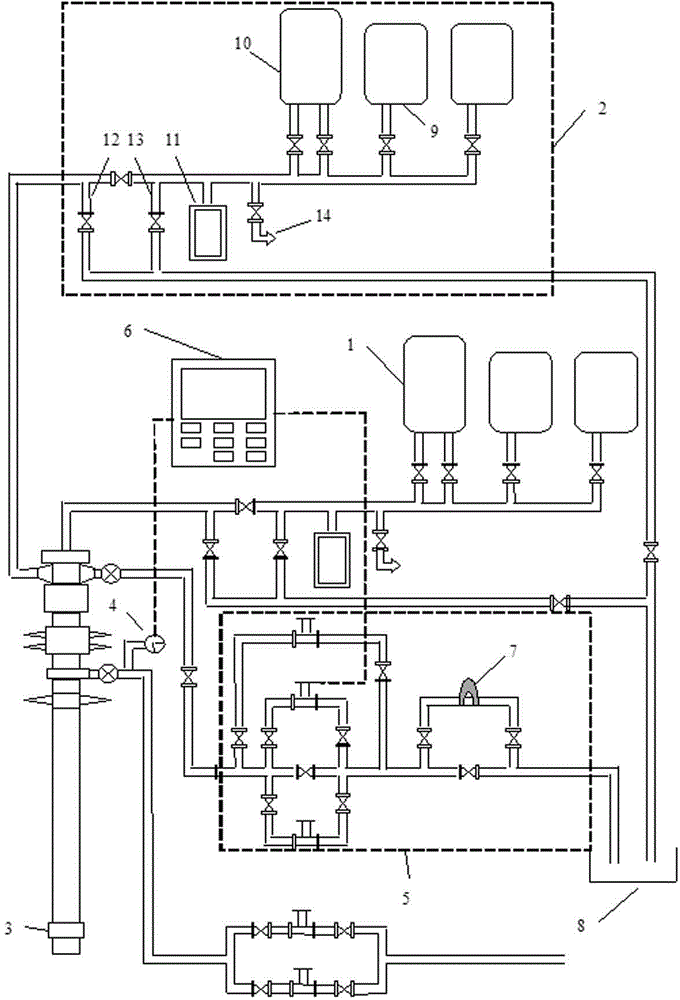

[0053] Attached below figure 1 The device of the present invention is further described.

[0054] The utility model relates to a pressure-controlled gas drilling device, which is modified on the basis of the existing gas drilling device. Existing devices mainly include air pressurization system, wellhead system, air pressure drilling rig and choke manifold of drilling rig, wherein the air booster system includes booster and / or air compressor, gas flow and pressure recorder, pressure relief pipe and / or bypass line, vent line, control valve. The modified device also includes a back pressure system and a fine detail manifold. The wellhead system is equipped with a rotary control head, and the back pressure system and the fine detail manifold are connected to the rotary control head.

[0055] Wherein: the back pressure system includes a supercharger and / or an air compressor, a gas flow and pressure recorder, a pressure relief pipe and / or a bypass pipe, an exhaust pipe, and a co...

Embodiment 2

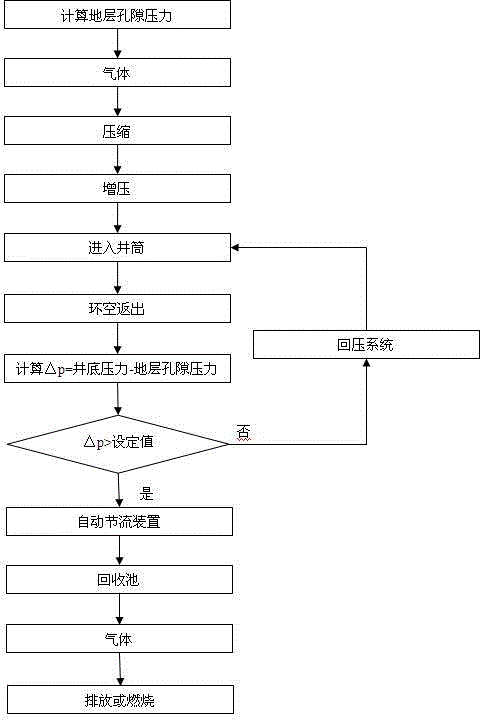

[0059] Refer to attached figure 2 , according to the device pressure-controlled gas drilling method of embodiment 1 is mainly:

[0060] (1) Formation pore pressure is calculated from well logging data, and formation pore pressure is calculated by Terzaghi model:

[0061] P o =P p +σ (1)

[0062] In the formula: P o is the overburden pressure; P p is the formation pore pressure; σ is the vertical effective stress.

[0063] Because the formation stress at different depths with the same acoustic time difference is the same, that is, the degree of formation compaction is the same; the degree of formation compaction is the same, and the skeleton stress of the rock is the same, that is, the same porosity corresponds to the same effective stress.

[0064] If the acoustic time differences of points 1 and 2 are the same and have the same effective stress, then:

[0065] σ 1 = σ 2 (2)

[0066] According to Terzagh formula:

[0067] P o1 =P p1 +σ 1 (3)

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com