Pipeline and pipeline with coupling

A pipeline and airgel technology, which is applied in the field of pipelines with couplings, can solve the problems that oil production pipelines cannot have thermal insulation performance, corrosion resistance and wear resistance, etc., so as to eliminate heat convection, improve thermal insulation performance, and improve The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the pipeline is not particularly limited in the present invention, and various existing methods for forming a multi-layer tubular structure can be used, which will not be repeated here.

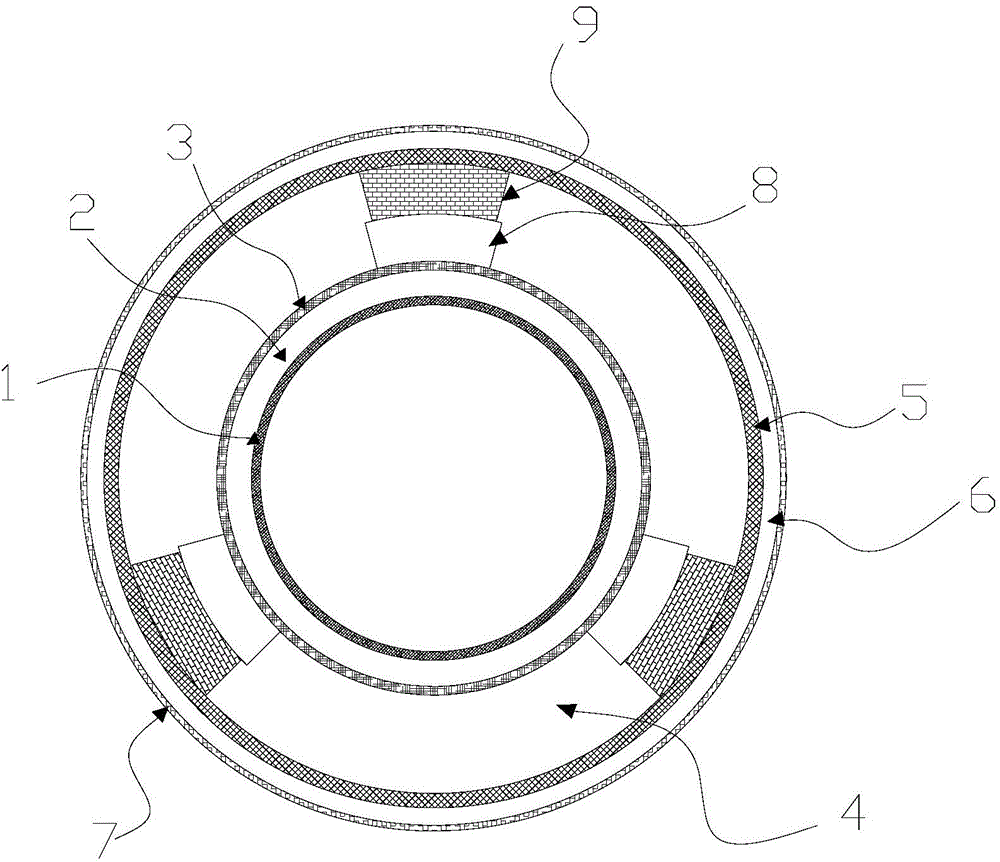

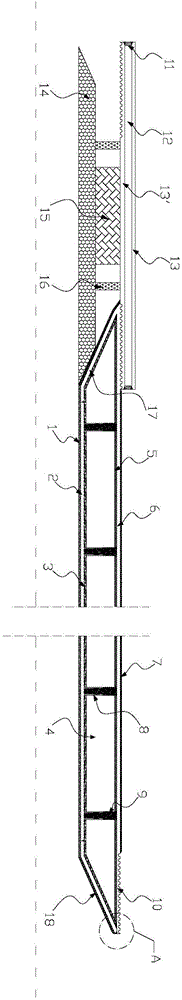

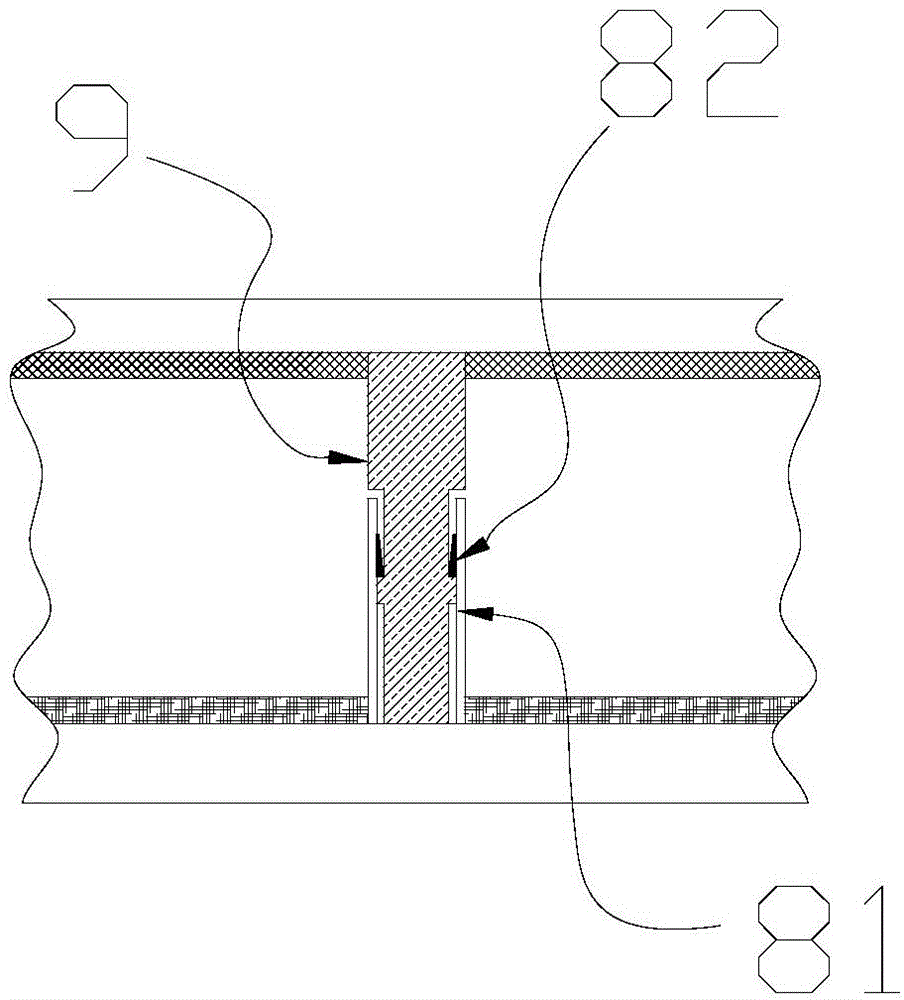

[0058] The pipe with coupling provided by the present invention includes at least two of the above pipes and at least one coupling. in, figure 2 It is an axial sectional view of the pipe with a collar.

[0059] According to the present invention, in order to facilitate the tight fit between the pipe and the coupling, preferably, the outer surface of the end of the pipe connected to the coupling has an external thread structure 10, and the coupling is corresponding The ground has an internal thread structure, so that the two are screwed together.

[0060] According to the present invention, in order to facilitate the tight fit between the pipe and the coupling, preferably, the end of the pipe connected to the coupling is provided with a flared joint 17 . Mo...

preparation example 1

[0081] This preparation example is used to illustrate the thermal insulation powder coating provided by the present invention and its preparation method.

[0082] (1) Spray the solution containing the surface modifier on the surface of the silica porous material:

[0083] Dissolve 5 grams of γ-(methacryloyloxy)propyltrimethoxysilane in absolute ethanol at a mass ratio of 3:100, stir until completely dissolved, and adjust the pH of the solution to 3 with oxalic acid , to obtain an ethanol solution containing γ-(methacryloyloxy)propyltrimethoxysilane. 200 grams of silicon dioxide porous material is added in the centrifuge mixing equipment, then 100 grams of the above-mentioned solution containing γ-(methacryloyloxy) propyltrimethoxysilane is sprayed on the surface of the silicon dioxide porous material and Mix at a low speed of 300r / min for 300min, then mix at a high speed of 2000r / min for 120min.

[0084] (2) Preparation of dry surface-modified silica porous material:

[008...

preparation example 2

[0094] This preparation example is used to illustrate the thermal insulation powder coating provided by the present invention and its preparation method.

[0095] (1) Spray the solution containing the surface modifier on the surface of the silica porous material

[0096] Dissolve 5 grams of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane in absolute ethanol at a mass ratio of 3:100, stir until completely dissolved, and use acetic acid to adjust the pH of the solution Adjust to 6 to obtain an ethanol solution containing N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane. 200 grams of silicon dioxide porous material is added in the centrifuge mixing equipment, then 100 grams of the above-mentioned solution containing N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane is sprayed on the surface of the silicon dioxide porous material On the surface, mix at a low speed of 500r / min for 300min, and then mix at a high speed of 2500r / min for 120min.

[0097] (2) Preparation of dry surface-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com