Combined steam smoke MGGH system and flue gas treatment technology

A technology of flue gas treatment and steam, which is applied in the direction of lighting and heating equipment, etc. It can solve the problems that the treatment process cannot fully meet the environmental protection requirements, the utilization rate of waste heat of flue gas is low, and the project cost is high, so as to reduce the grade of steam, reduce loss, reduce The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

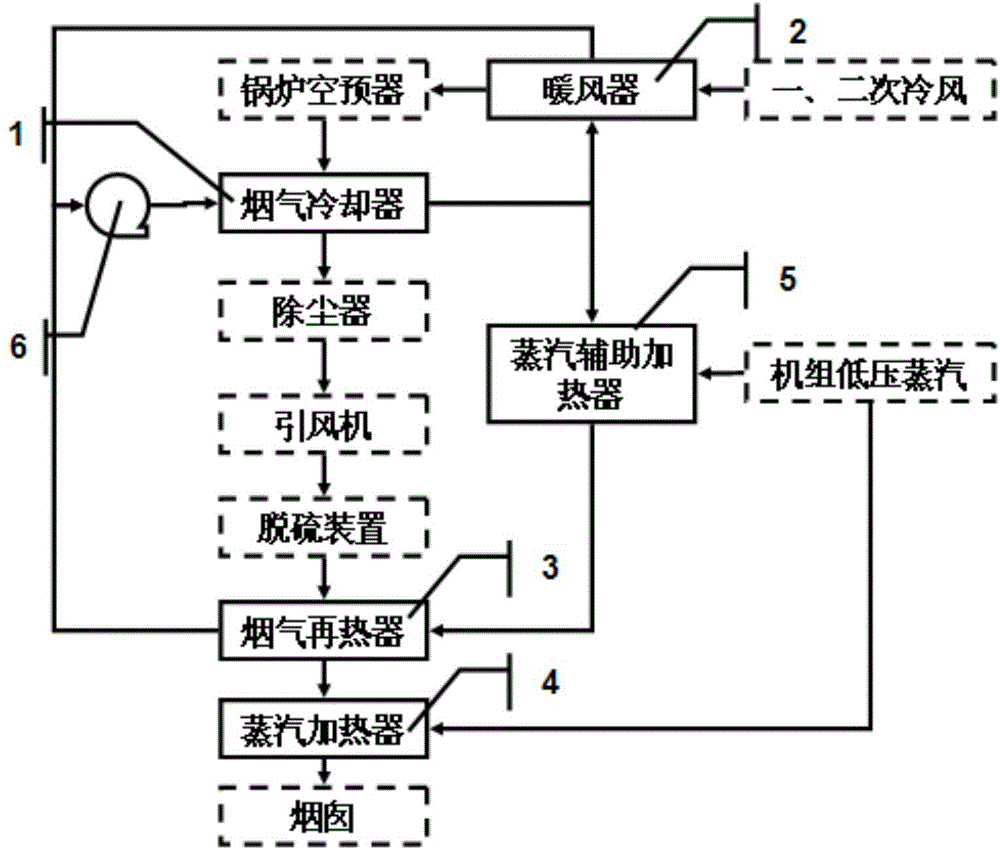

[0034] According to attached figure 1 As shown, this embodiment provides a combined steam flue gas MGGH system. A flue gas cooler 1 is installed on the connecting flue between the boiler air preheater and the dust collector, and a flue gas cooler 1 is installed on the connecting flue between the desulfurization device and the chimney. The flue gas reheater 3 and the steam heater 4, the air heater 2 is installed on the inlet duct of the boiler air preheater, and the steam is installed on the circulating water pipe of the hot section between the flue gas cooler 1 and the flue gas reheater 3 Auxiliary heater 5, a dust collector, an induced draft fan and a desulfurization device are installed between the flue gas cooler 1 and the flue gas reheater 3, and circulating water in the cold section between the flue gas cooler 1 and the flue gas reheater 3 A variable frequency circulation pump set 6 is installed on the pipeline, and a circulating water pipeline connected between the flue ...

Embodiment 2

[0039] This embodiment provides a combined steam flue gas MGGH system. A flue gas cooler 1 is installed on the connecting flue between the boiler air preheater and the dust collector, and a flue gas recooler is installed on the connecting flue between the desulfurization device and the chimney. Heater 3 and steam heater 4, steam auxiliary heater 5 is installed on the hot section circulating water pipeline between flue gas cooler 1 and flue gas reheater 3, and steam auxiliary heater 5 is installed between flue gas cooler 1 and flue gas reheater Set dust collector, induced draft fan and desulfurization device between flue gas cooler 1 and flue gas reheater 3; A circulating water pipeline valve adjustment system connected between the gas reheater 3, steam auxiliary heater 5 and frequency conversion circulating pump group 6 is installed, and a steam and condensed water pipeline valve adjustment system is installed on the steam heater 4 and steam auxiliary heater 5.

[0040] Using ...

Embodiment 3

[0050] This embodiment provides a combined steam flue gas MGGH system. A flue gas cooler 1 is installed on the connecting flue between the boiler air preheater and the dust collector, and a flue gas recooler is installed on the connecting flue between the desulfurization device and the chimney. Heater 3 and steam heater 4, the heater 2 is installed on the inlet air duct of the boiler air preheater, and the steam auxiliary heater is installed on the hot section circulating water pipe between the flue gas cooler 1 and the flue gas reheater 3 5. Install dust collector, induced draft fan and desulfurization device between flue gas cooler 1 and flue gas reheater 3, and install on the cold section circulating water pipeline between flue gas cooler 1 and flue gas reheater 3 Frequency conversion circulating pump unit 6, a circulating water pipeline valve adjustment system connected between flue gas cooler 1, heater 2, flue gas reheater 3, steam auxiliary heater 5 and frequency conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com