Method for measuring content of indium in zinc concentrate

A technology for indium content and zinc concentrate, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of high cost, inaccurate results, and complicated methods for determining indium content, and achieves low cost, accurate results, and avoids repeated analysis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

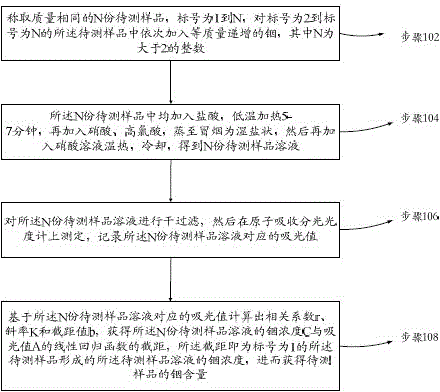

Method used

Image

Examples

Embodiment 1

[0042] Weigh 5 parts of 0.25g sample into a 250mL beaker, add 0, 10, 20, 40, 80μg indium standard in turn, add 15mL hydrochloric acid, cover the watch glass, heat at low temperature for 5-7 minutes to make the sulfur in the sample convert to hydrogen sulfide Form is volatilized, add 5mL nitric acid, 5mL perchloric acid, cover the watch glass, steam until it becomes a wet salt like smoke, cool, add 10mL of 5% nitric acid solution accurately, warm for a while to dissolve the salt, cool, dry filter Solution, the absorbance value is measured according to the optimized conditions selected by the instrument, the absorbance value is the independent variable, and the concentration corresponding to the added indium standard solution is the dependent variable. Through the CORREL and INTERCEPT functions in the EXCEL software, the correlation coefficient r and the intercept value b in the group of measurements are calculated respectively, and the volume of the solution is multiplied by b a...

Embodiment 2

[0044] Weigh 4 parts of 0.5g sample into a 250mL beaker, add 0, 10, 20, 30μg indium standard in turn, add 15mL hydrochloric acid, cover the watch dish, heat at low temperature for 5-7 minutes to volatilize the sulfur in the sample in the form of hydrogen sulfide , add 5mL of nitric acid and 5mL of perchloric acid, cover the watch dish, steam until the smoke becomes wet salt, cool, add 10mL of 5% nitric acid solution, warm for a while to dissolve the salt, cool, and use 5% volume fraction Dilute the nitric acid solution to a 50 mL volumetric flask, and mix well. Take the dry filtered solution, and measure the absorbance value according to the optimized conditions selected by the instrument. The absorbance value is the independent variable, and the concentration corresponding to the added indium standard solution is the dependent variable. Through the CORREL and INTERCEPT functions in the EXCEL software, the correlation coefficient r and the intercept value b in the group of mea...

Embodiment 3

[0046] This implementation example illustrates the determination result of this method to the relatively high content of indium in zinc concentrate.

[0047] Weigh 4 parts of 0.5000g sample into a 250mL beaker, add 0, 40, 80, 120μg indium standard in turn, add 15mL hydrochloric acid, cover the watch glass, heat at low temperature for 5-7 minutes to volatilize the sulfur in the sample in the form of hydrogen sulfide , add 5mL of nitric acid and 5mL of perchloric acid, cover the watch dish, steam until the smoke becomes wet salt, cool, accurately add 10mL of 5% volume fraction of nitric acid solution, warm for a while to dissolve the salt, cool, and use 5% volume Dilute the fraction of nitric acid solution to a 50 mL volumetric flask, and mix well. Dry filter the solution, measure the absorbance value according to the optimized conditions selected by the instrument, take the absorbance value as the independent variable, and the concentration corresponding to the added indium sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com