A method for reproducing touch screen panel employing vacuum

A touch screen and panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as damage, reduced adhesion, breakage or damage, and achieve improved separation rate, easy separation, The effect of minimizing damage and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

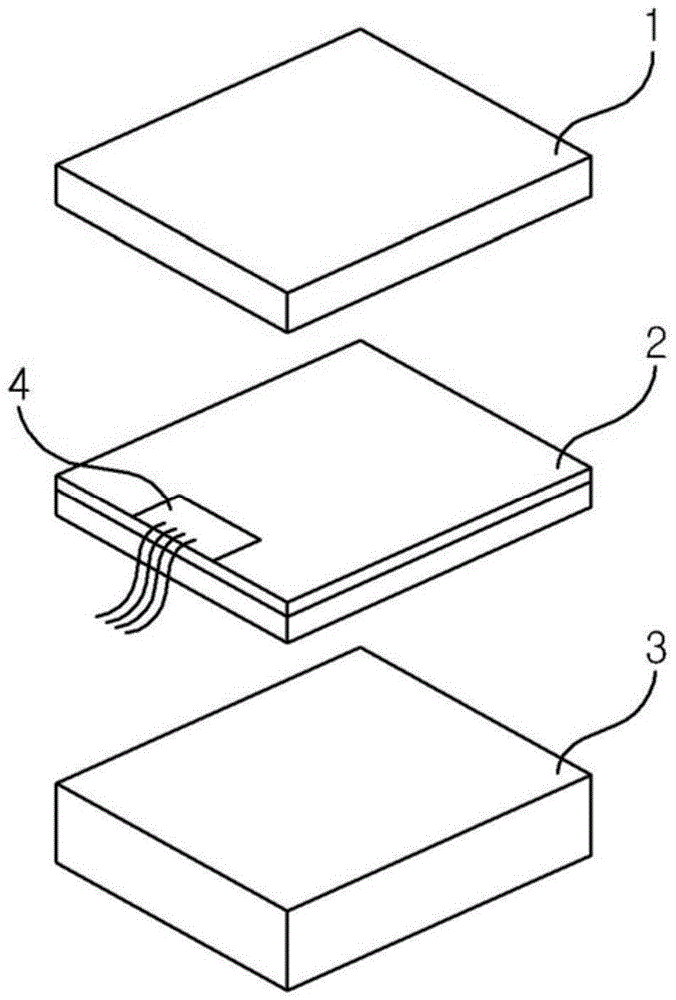

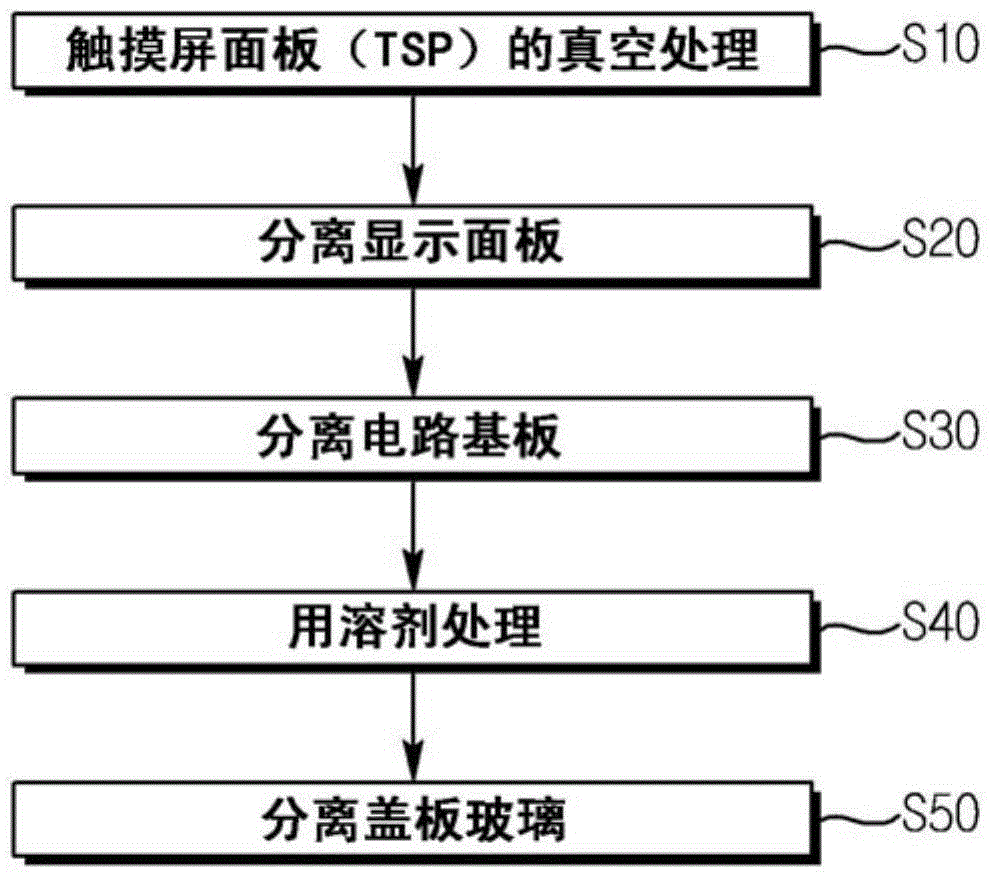

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Vacuum treatment of TSP at sub-zero temperatures

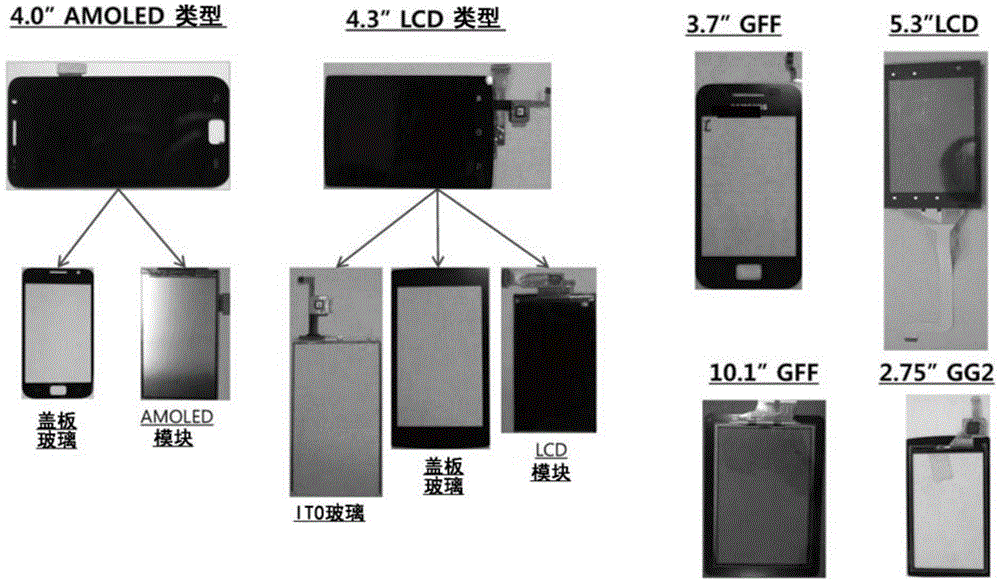

[0065] Move 10 TSPs of 4.0″AMOLED (active-matrix organic light-emitting diode: active matrix organic light-emitting diode) type and 10 TSPs of 4.3″LCD type to the fixture, and put them into the vacuum chamber at one time (manufacturer : HANBAEK SCIENTIFIC).

[0066] Then, after the first cooling of cooling the temperature of the vacuum chamber to -20°C to -30°C at a rate of 5°C / min, after 5 minutes, the second cooling of cooling to -50°C to -80°C is carried out (Examples 1-1, 1-2, 1-3 and 1-4). In addition, within 10 minutes, the vacuum is maintained at -760mmHg for a time ranging from 1 to 10 minutes. Thereafter, the display panel (LCM) and the FPCB were separated from the product by hand by releasing the vacuum for 10 minutes and taking out from the jig.

Embodiment 2

[0067] Example 2: Vacuum treatment of TSP at temperatures above zero

[0068] After moving 10 each of 4.0″AMOLED type TSP and 4.3″LCD type TSP to the jig, they were placed in a vacuum chamber (manufacturer: HANBAEK Science) at one time.

[0069] Then, the temperature of the vacuum chamber was raised to 50-80°C at a rate of 5°C / min (Example 2-1, 2-2, 2-3 and 2-4), and within 10 minutes, the temperature was increased to 760mm Hg is maintained under vacuum for a time in the range of 1 to 10 minutes. Thereafter, the display panel (LCM) and the FPCB portion were separated from the product by hand by releasing the vacuum for 10 minutes and taking it out from the jig.

Embodiment 3

[0070] Embodiment 3: According to the separation effect measurement of different vacuum treatment conditions

[0071] In Examples 1 and 2 above, the degree of separation between the display panel (LCM) and the FPCB was measured. That is, 10 operators sequentially separated the display panel (LCM) and the FPCB part by hand for each of the 10 TSPs, and inspected the appearance for evaluation.

[0072] The evaluation criteria are: based on the standard in Table 1, the full score is 10 points, the results of Example 1 are shown in Table 2, and the results of Example 2 are shown in Table 3.

[0073] 【Table 1】

[0074] Fraction

Result representation

Remark

9~10 minutes

◎

Easy to separate by hand, good appearance

7 to 8 points

○

Not easy to separate by hand, but looks good

5 to 6 points

△

Easy to separate by hand, but poor appearance

less than 5 points

X

Difficult to separate by hand and poor appearance...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap